TRAFFIC NOISE: Current growth in the use of electric cars is providing environmental benefits far beyond simply reducing CO2 emissions. Reductions in traffic noise, for instance. Firstly, an electric motor makes less noise than a conventional engine and secondly, most electric cars are fitted with specially-developed low rolling resistance (EV) tyres that make less noise than traditional car tyres.

Facts:

The World Health Organisation (WHO) has demonstrated that there is a clear link between heart and pulmonary diseases and noise exposure at levels above approx. 58 dB.

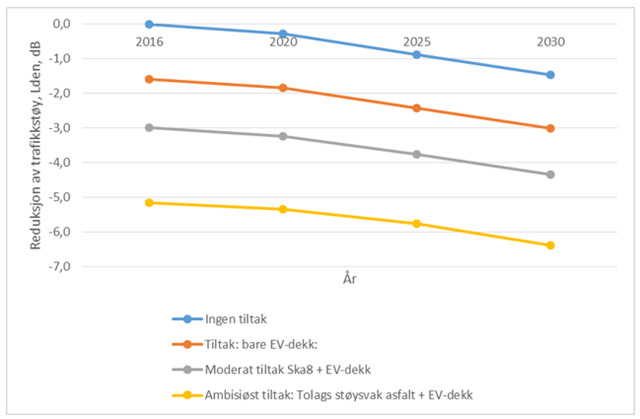

Current international initiatives such as more stringent noise limits for cars and car tyres will only have a limited effect up until 2030 (see figure). If Norway is to achieve its target of reducing the number of people affected by noise nuisance by 10 per cent by 2020, additional local measures must be put in place. Examples of such measures that may help towards achieving this target are a combination of lower-noise car tyres and road surfacing.

The results of the research project LEO (Low Emission Optimized tyres and road surfaces for electric and hybrid vehicles) show that such a combination could make a contribution. The winning combination provided a reduction in rolling noise of the order of 10 dB which, to the human ear, represents a noise reduction of one half.

About 750,000 people in Norway find themselves in this risk zone and, statistically, between 60 and 100 persons will die in Norway each year as an indirect result of noise exposure. Source: SINTEF.

This is why a team of researchers have recently been looking into whether the benefits of EV tyres can be exploited to help reduce noise in more conventional traffic situations.

But tyres aren’t the only things that the researchers have had under the microscope. They’ve also been looking into different kinds of road surfacing textures, because these can also contribute towards noise reduction.

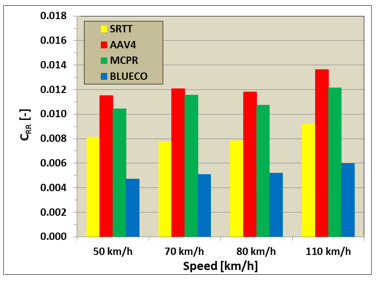

The figure below shows the rolling resistance coefficient for four different types of tyre, where MCPR represents a conventional “standard” passenger car tyre, and BLUECO an EV tyre manufactured by Continental. The results show the average values for 80 different road surfaces. On average, the EV tyre exhibits a rolling resistance that is approx. 40% lower than that for the conventional tyre. This can lead to a reduction in energy consumption of the order of between 12 and 16 per cent in built-up areas, and between four and eight per cent on out-of-town highways.

“The results show that there is a massive potential for reducing both traffic noise and fuel consumption linked to conventional cars by combining low-noise tyres and the right kind of road surfacing”, says Truls Berge, an acoustics researcher at SINTEF.

His experiments have been carried out as part of a joint project between SINTEF and Gdansk Technical University (TUG, in Poland) called LEO (Low Emission Optimized tyres and road surfaces for electric and hybrid vehicles).

Rolling resistance holds the key

The project has involved recording a large volume of data using a variety of combinations of road surfaces and car tyres, including those specially developed for electric cars. The aim was to discover combinations beneficial to reducing both traffic noise and CO2 emissions produced by conventional cars, and for extending the range of electric cars.

What happens if we leave things as they are and simply observe the results of imposing international noise regulations on cars and car tyres, set against the use of a combination of low-noise asphalt and car tyres? SMA8 refers to road surfacing with a denser surface and smaller aggregate size. Experiments using SMA8 surfacing have been carried out in Norway during the period 2012-2015 and have been shown to exhibit lower noise properties than traditional surfaces such as SMA11 and SMA16, even after having been exposed to winter conditions and studded tyres.

The winning combination provided a reduction in rolling noise of the order of 10 dB which, to the human ear, represents a noise reduction of one half.

The experiments were carried out on test tracks with a wide variety of road surfacing textures, as well as on ordinary public roads and in the laboratory.

The results showed that the road surfacing texture was very important. However, for four of the EV tyre brands rolling resistance was reduced by an average of 40 per cent. Based on theoretical calculations, this provides a potential reduction in energy consumption of between 12 and 16 per cent at constant speeds of 50 km/h in built-up areas, and between four and six per cent at 80 km/h.

“For example, the measurements showed that a SMA8 surface that was tested in Norway in the period 2012-2015, and which is known to provide minor levels of noise reduction, exhibits a difference in rolling resistance of 23 per cent when comparing an EV tyre manufactured by Continental (standard on electric VW Golfs) with a popular brand manufactured by Michelin”, says Berge.

Technology transfer

“The results, which demonstrate a reduction in both noise and energy consumption, raise the interesting issue of a technology “transfer” by which conventional cars could be fitted with tyres developed for electric cars, combined with a re-assessment of what road surfacing textures should be used in heavy traffic areas. This may be of particular relevance in locations where it is impractical to implement conventional measures such as noise barriers”, says Berge, who believes that in a few years’ time, we will be seeing many low-noise tyre brands on the market.

Climate change is a key driver of the development of low rolling resistance tyres because of the way they reduce energy consumption. Extra benefits in the form of noise reduction are a welcome bonus.

Facts about the LEO project:

During the period 2013-2016, SINTEF and the Gdansk Technical University (TUG) have been working together on the project called LEO (Low Emission Optimized tyres and road surfaces for electric and hybrid vehicles), which is being funded by the Polish-Norwegian Research Programme CORE 2013 (NCBiR – EEA agreement, Norway Grants).