Norway has a unique position in the world, i.e. an enormous expertise in environmentally-friendly, cost-effective drilling accumulated during the decades of safe and successful hydrocarbon production. This gives Norway an advantage and allows it to take the lead in the development of cost-effective technologies for deep geothermal drilling.

The technology developed within this project can readily be applied to other areas and can be used for a wide range of rock penetration methods, ranging from smaller wellbores (geothermal, subsurface infrastructure like power cables or district heating/cooling, and oil) to large tunnels (road/rail infrastructure). Another area that has a direct relevance and a solid industry base in Norway is drilling tunnels for hydroelectric plants.

NEXT-Drill is a 4-year long Knowledge Building Project performing from 2012 to end of 2015, granted within the RENERGI program of the Research Council of Norway (former ENERGIX program) with a total budget of 24 MNOK.

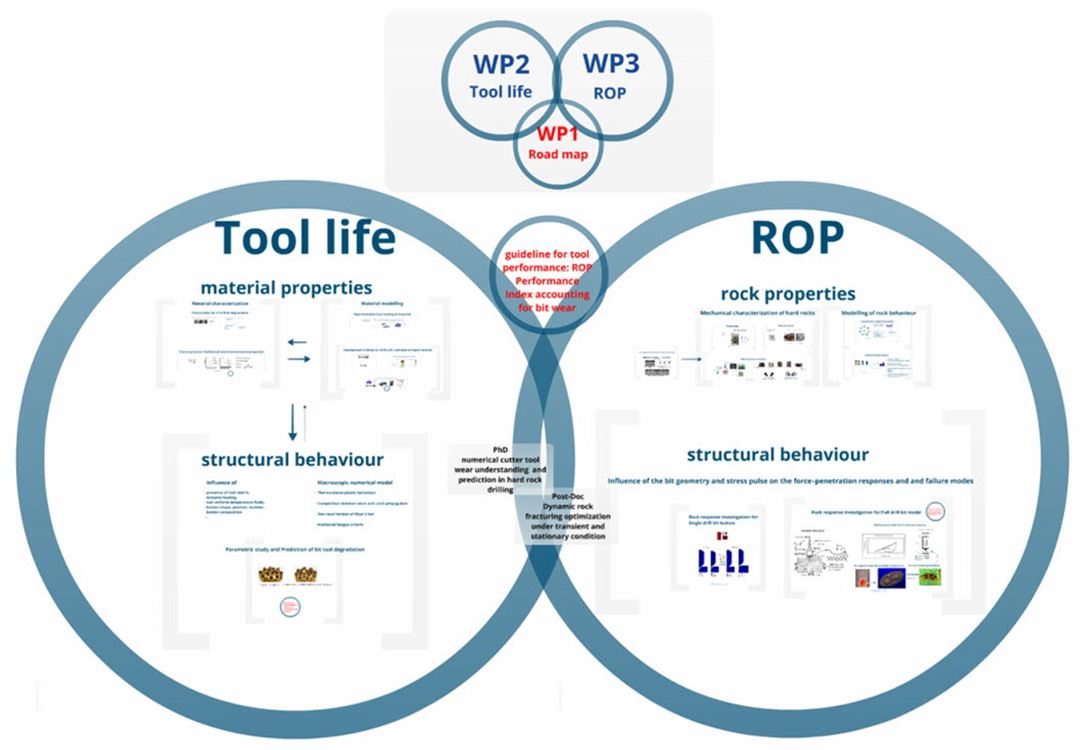

To fulfill the main objectives, the three following research axes are followed:

- Survey and integrate basic R&D and industrial technologies for the identification of technology roadmaps and infrastructure. This axe is mostly carried out by IRIS research institute, where a yearly workshop is also organized to gather industrial and academic contributors.

- Establish test methods for characterization of the fundamental mechanisms of hard rock fracturing induced by dynamic bit-rock interactions

- Establish an experimentally validated numerical model for rock fracturing and tool/rock interaction studies, and to make it available for industrial exploitation.

The two last research axes are mostly carried out by SINTEF/NTNU, where experimental and numerical facilities are extensively used, for testing on both hard rock material and tungsten carbide inserts.

The industrial consortium covers the value chain for drilling: Statoil, BP, LKAB-Wassara, Sandvik, H.C.Starck, Rock Energy, Norhard and Resonator. All industrial partners have contributed to the research activities providing 30% of the total budget and in-kind contributions such as data or experimental facilities. In addition to the Norwegian research partners SINTEF, IRIS, NTNU and UiS, international research partners such as Mines ParisTech (France), University of Minnesota (USA) and University of Tampere (Finland) are strongly involved in the research activities.

For more information about the project, see the Blog posts below