Solvent studies is essential in the work with developing post combustion CO2 capture technologies. Solvent degradation may lead to a significant loss of solvent performance (solvent losses, corrosion problems etc.) and also lead to a negative environmental impact (emissions to air, production of special waste).

Degradation studies are an important part of screening activities of new solvents but also important in characterizing degradation properties of developed solvents. The degradation of solvent is often classified as oxidative and thermal degradation.

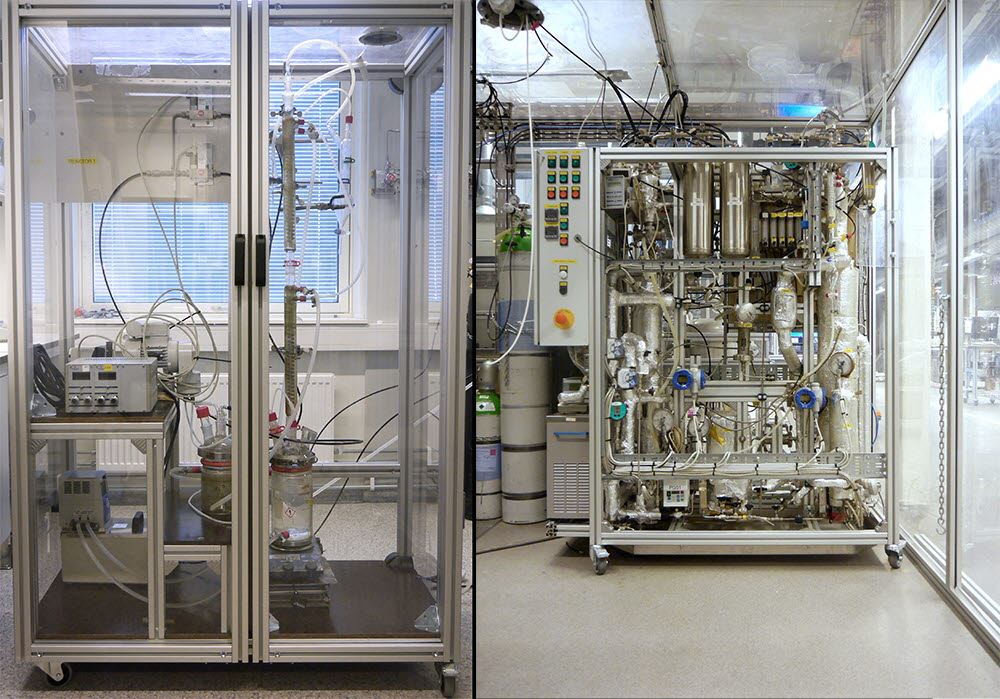

At SINTEF we have apparatus to study separate oxidative and thermal degradation (Oxidative degradation rig and thermal degradation set-up). Metal concentration in samples after thermal degradation experiments have shown to give good qualitative data with respect to corrosivity of solvents.

In addition SINTEF has two solvent degradation rigs (SDR) which enables to study the different degradation mechanisms occurring in a real-life process. The test rig simulates realistic temperatures and solvent CO2 loadings found in absorber/stripper configurations for CO2 capture. The solvent is cycling in a combined absorber and stripper setup where the temperature of the absorber and stripper could be set at different temperatures. The flue gas is a synthetic mixture of different gases and the composition is possible to vary.

The degradation studies are done in close collaboration with SINTEF'S well equipped MS-Lab which includes a wide range of mass spectrometric techniques. This collaboration enables full characterization (degradation compounds and impurities) of the solvent.