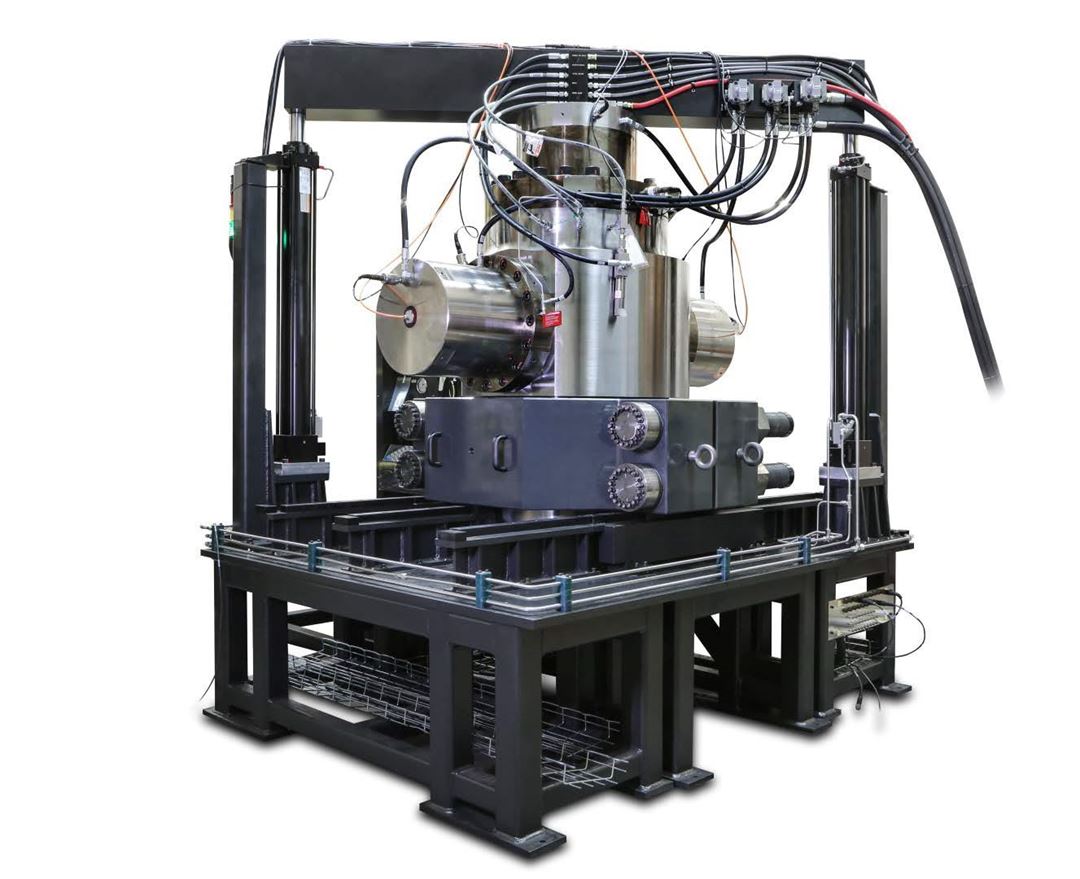

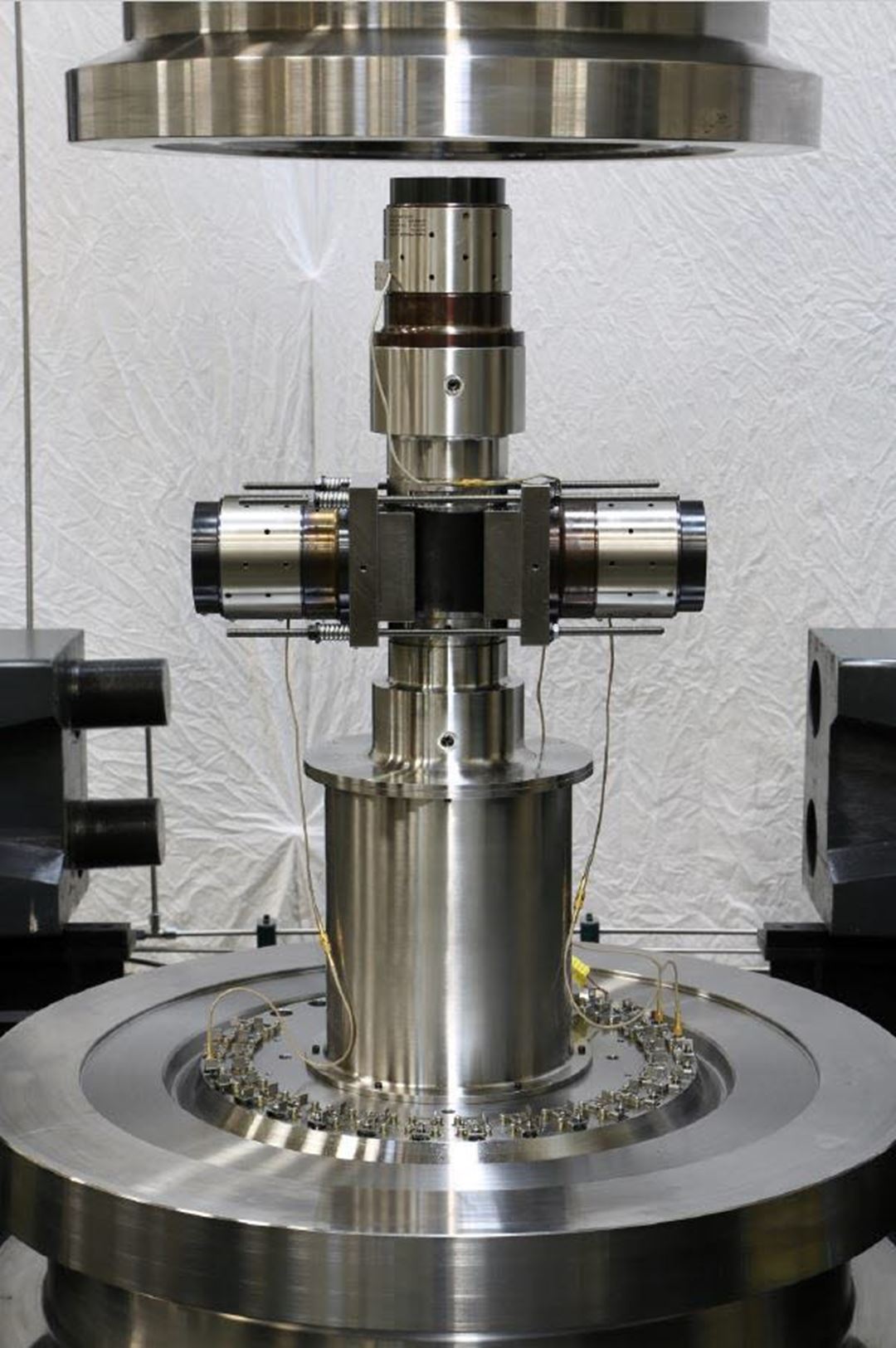

True triax

Contact person

Specifications

- 100 MPa confining stress

- 50 MPa vertical deviatoric stress

- 50 MPa horizontal deviatoric stress

- Truncated samples, 200 mm diameter (and 400 mm diameter in biaxial mode)

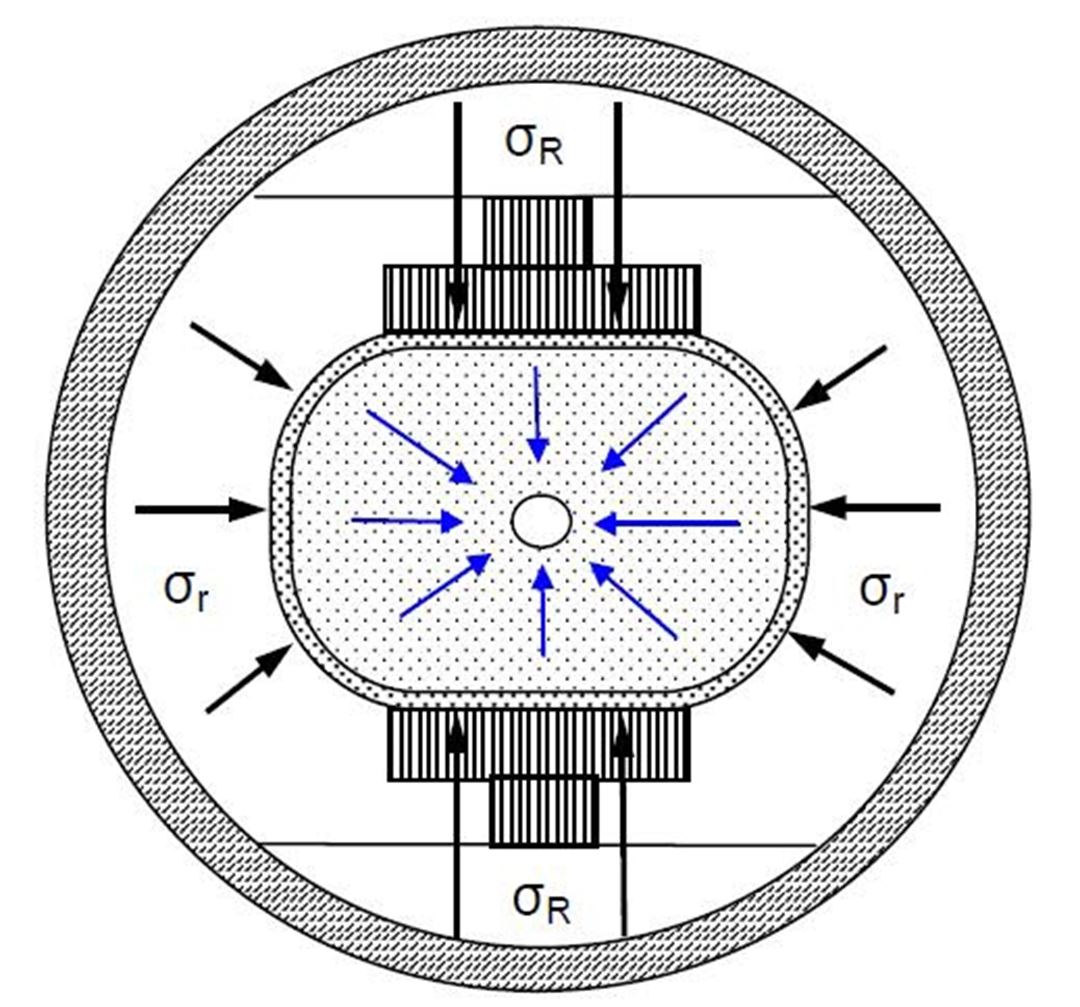

- Hollow-cylinder tests

- Radial flow

Specimens

Different geometry and sizes

Truncated samples (true triaxal-mode)

- 200 mm specimens

- 100 mm specimens

- 50 mm specimens

Round specimens (biaxial-mode)

- 400 mm specimens

Typical length to diameter ratio: 1:1

Areas of use

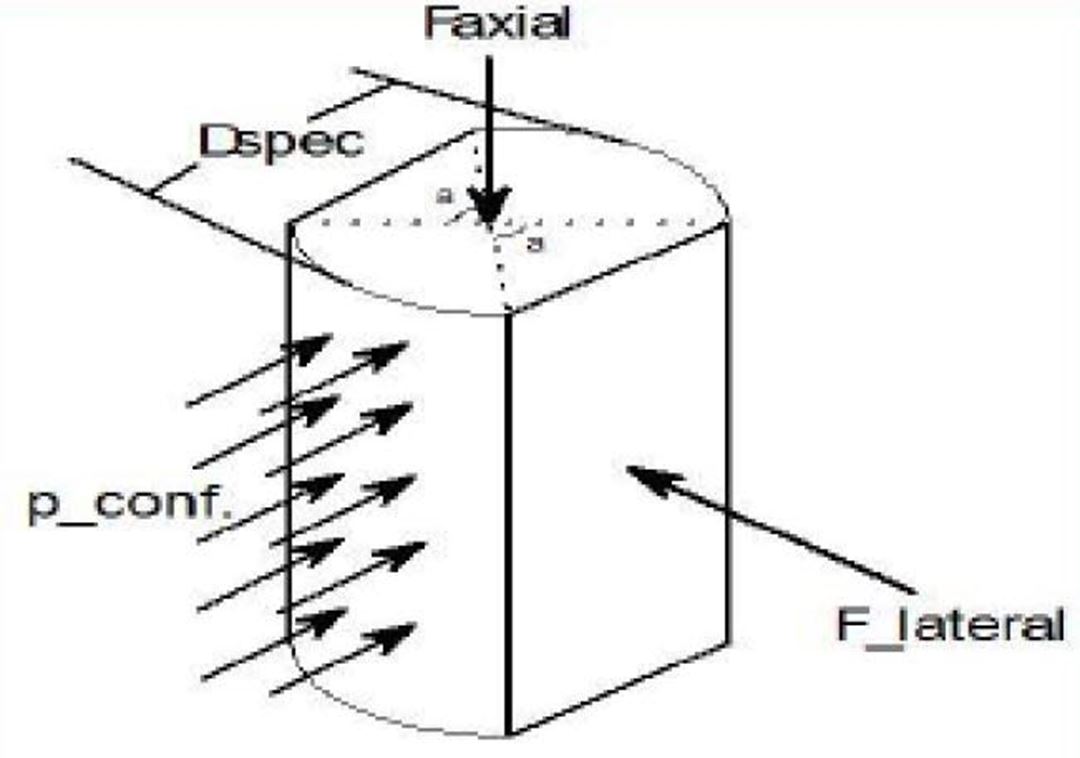

Sand production

the True Triaxial system will help refine sand prediction models to take into account field-relevant stress anisotropy around a well. This will improve the predictive accuracy of volumetric sand production models, helping operators optimize well productivity throughout its lifetime.

Borehole stability

The new system will allow for more realistic testing of overburden shale samples, especially targeting difficult deviated trajectories, where stress anisotropy has a large destabilizing effect. The interaction between stress anisotropy and fabric anisotropy will be studied in more detail.

Gas and oil shales

Testing will improve models of fracture productivity as a function of well orientation and stress.

Hydraulic fracturing (for larger samples, up to 400 mm)

The rig will permit more accurate hydraulic fracturing tests, used in biaxial mode on the largest samples to allow for longer fractures. Additionally, the effect of stress anisotropy on fracture topology can be studied on smaller samples.

Any other area where non-isotropic stress distribution is essential (i.e. most areas).

Pictures and video

Contact information

Postal address: P.O. Box 4763 Torgarden, NO-7465 Trondheim

Visiting address: S.P. Andersens vei 15 B, NO-7031 Trondheim

Phone: +47 464 17 000