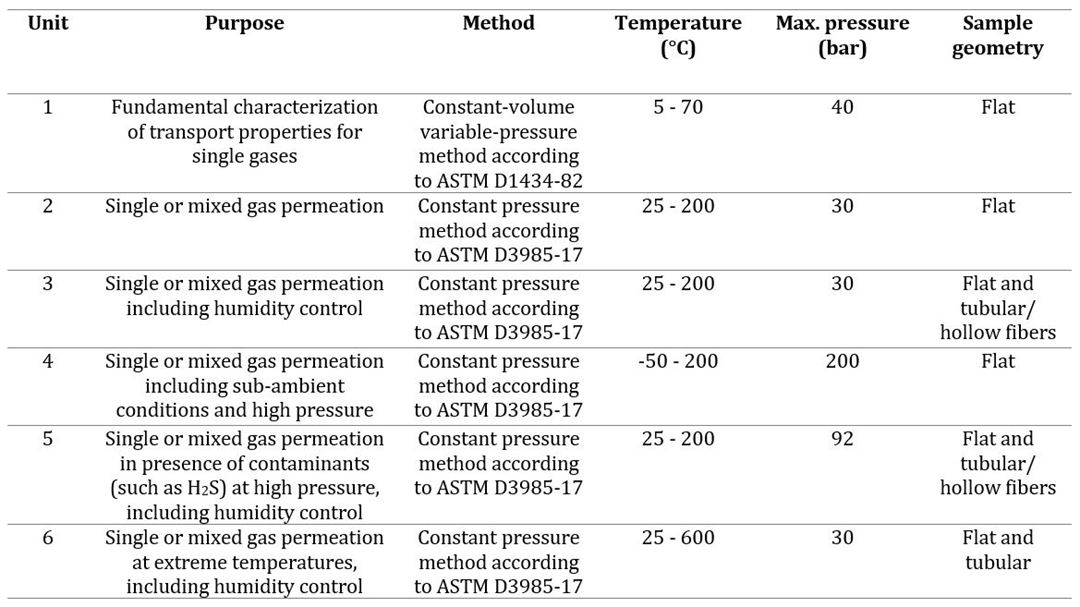

Equipment available for evaluating single and mixed gas permeation, presence of contaminants (such as H2S, NOx etc.), under normal and extreme conditions.

The laboratory is equipped with various experimental facilities covering a range of experimental conditions, from sub-ambient to high temperature (-50 to 600oC), and from atmospheric to high pressure (200 bar ). Measurements are performed using either the constant-volume variable pressure or the constant-pressure method.

- Constant volume variable pressure method (according to standard ASTM D1434-82, procedure M) is pressure-based, and for this reason, only single gas can be measured. Diffusivity (D) and solubility (S) can be determined from the permeation time-lag.

- Constant pressure method (according to standard ASTM D3985 – 17) uses gas chromatography (GC) analysis to determine gas composition of the permeated components. For this method, diffusivity (D) and solubility (S) can also be determined from the permeation time-lag, but this can be challenging for fast permeating components due to analysis delays with the GC.

The laboratory is based around a comprehensive gas infrastructure which allows for controlled gas mixtures of O2, H2, N2, CO, CO2, CH4, Ar and He. In addition, other gases and pre-mixed gas bottles can be acquired and connected to the equipment if desired. Extensive safety precautions have also been made for running experiments with flammable and toxic gases such as H2S and NH3. For instance, they are equipped with wall-mounted gas detectors and magnetic valve closing of the gas supply in case of an emergency.

All equipment units are connected to LabVIEW software, allowing for continuous long-term testing and monitoring.

This laboratory is typically used for, but not limited to:

- Fundamental characterization of transport properties for membrane materials (P, D and S)

- Performance and stability of polymeric membrane for CO2 capture or biogas upgrading (have tested membrane area up to 0.5 m2)

- Performance evaluation of barrier materials for gases under extreme conditions (have tested sample’s thickness up to 5 mm)

- Membrane evaluation in humid H2S natural gas feed streams

Equipment

An overview of available experimental facilities at this laboratory at SINTEF, and their characteristics, are given in the table below. Note that this is for current configuration and modifications can be done to accompany specific needs.