Biofuels are foreseen as a promising alternative to today's fossil fuels, given their potential to substitute fossil fuels in the existing energy supply infrastructure. In contrast, intermittent renewables such as wind and solar energy are clearly more challenging considering the ways energy is distributed and consumed, particularly in the heavy transport sector.

Biofuels are often categorized by their generations. Biofuel generations are mainly determined by the feedstock resources used for fuel production.

The production of first generation biofuels (bioethanol, biodiesel) employs specially cultivated biomass, often food crops. The production technologies for these biofuels are well established. However, first generation biofuels have several issues such as direct or indirect competition with food production, low production yields and lower CO2-saving potentials compared to second and third generation biofuels. On the other hand, second generation technologies process lignocellulosic based feeds, primarily for diesel and ethanol production. The production processes, in this case, are more complex, costly and they are not commercially available yet.

Sustainable, second generation biofuels are and will be essential in decarbonization of the heavy transport segment, such as aviation, marine and long-haul road transportation. In Norway, for instance, aviation is a major transportation mean for people and goods. Aviation is a significant contributor of the world's economy. Aviation's role is expected to increase in the future and with it the fuel demand and the environmental impact. The expected increased CO2 emissions are of major concern and emission-reducing measures such as the replacement of fossil fuels by biofuels are strongly recommended and expected.

Third generation biofuels are produced from aquatic biomass, with microalgae and macroalgae as two major feedstock resources. The production of these biofuels employs existing conversion routes applied for first and second generation biofuels. The challenges associated with third generation biofuels are the high prices and the limited availability of the so called blue biomass feedstock.

We work within these areas:

- Generic up-to-date information about biofuels through participation in professional and scientific committees

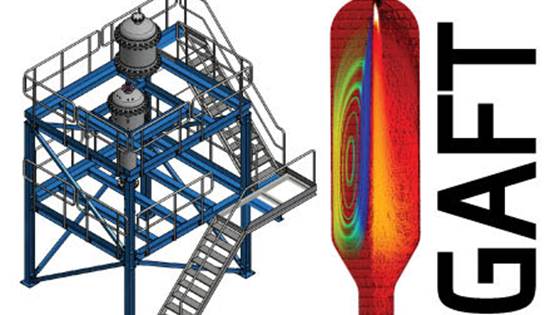

- Thermochemical biofuels conversion pathways (with gasification and hydrothermal liquefaction as main focus areas)

- Second and third generation biofuels, with particular focus on aviation biofuels and algal biofuels

- Value chain analysis

- Techno-economic studies

Methods

Our projects range from feasibility studies to laboratory testing from micro to bench-scale. We are specialists in value chain assessments with a strong techno-economic component and have experimental facilities covering the majority of the relevant value chains.

Why choose SINTEF?

SINTEF offers an industrially relevant multidisciplinary approach integrating experimental and modelling work, with unique laboratory infrastructure to conduct research on biofuels production technologies and in-house models for reactor development and value chain assessments. This approach is complementary with our participation in professional and scientific committees, such as the European Biofuels Technology Platform, European Energy Research Alliance and IEA Bioenergy, with first-hand strategic information to provide to our clients, both at national and international level. We work with Norwegian and international industry across the whole value chain, from raw material suppliers to technology providers and end-users.