We conduct research for improving and retrofitting existing systems, and for developing novel solutions for both the design and control of industrial process systems.

We work in these areas:

- Optimization of processes for liquefaction of natural gas and hydrogen.

- Process integration (heat integration, exergy analysis) of industrial processes.

- Optimal design of heat exchangers and heat-recovery systems (cycles).

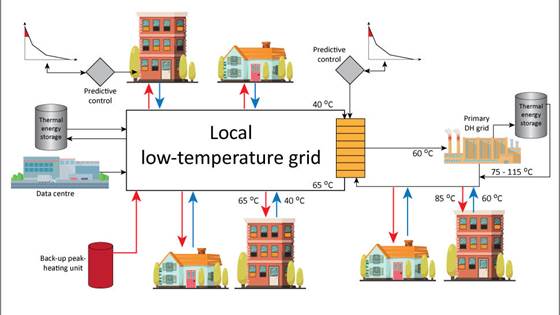

- Optimized solutions for utilization of industrial surplus heat.

- Model predictive control (MPC) of district heating and thermal grids.

Methods:

Our projects within process optimization involves developing suitable simulation and optimization models, incorporate process knowledge and available measurement data from the plants, interact with the plants engineers to adjust and verify the models, and apply mathematical optimization or thermodynamic methods to optimize the relevant processes or units. We use both commercial and open-access optimization and modelling tools and we develop in-house software.

Typical projects for us are:

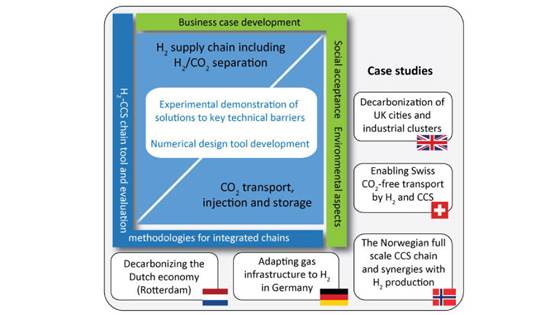

- Optimization of process flowsheets for various criteria.

- Optimal design of unit operations in hydrogen production from natural gas.

- Optimization of operating conditions for CO2 capture processes.

- Optimal design of thermal grids utilizing surplus heat sources.

- Analysis of optimized control solutions for thermal energy storage.