The process design includes finding the optimum relative load between the heat supplies: solar heat, waste heat, heat from energy storage, and steam power generation. We also perform optimisation with regards to footprint to enable the retrofit integration of solar heating in existing industrial processes.

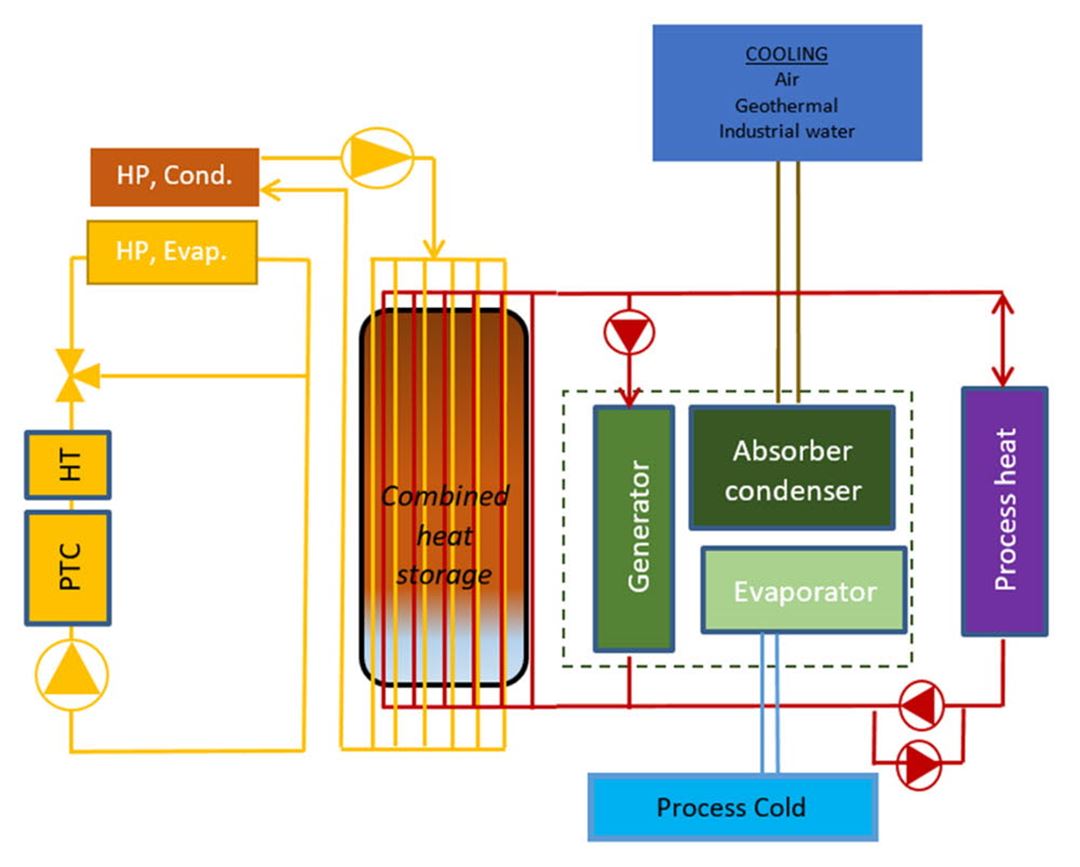

In addition to process design, we have the expertise to model and design specific components required for integrating solar heating in industrial processes. Examples are:

- Parabolic trough collectors (PTC) – the devices that collect the solar heat

- Electric heaters (HT) – used to compensate for the varying solar heat due to the weather conditions

- Heat pumps (HP)

- Evaporators

- Compressors

- Expansion valves

- The heat storage system – based on phase change material or storage of sensible heat in, e.g., oils

- Absorption chillers – to provide the required process cooling

We perform cost estimation of specific components and the overall process. Detailed cost estimates for the systems are challenging due to the variety of configurations, settings, temperature levels, and environmental conditions that the systems will encounter.

SINTEF combines knowledge on component modelling, process design, and cost optimisation to determine the best possible way to integrate solar heating and waste heat recovery for any specific industry. A collaboration with SINTEF can enable the integration of solar and waste heat in various sectors and provide the possibility to unlock attractive funding opportunities to help enterprises achieve net-zero by 2050.

Background:

The European Green Deal sets the ambition of a climate-neutral EU by 2050. The use of fossil fuels must be dramatically curtailed if the EU is to achieve this goal.

Solar thermal, possibly integrated with waste heat, can help meet the target by fulfilling a large amount of heat demand in industrial and agricultural processes.

Combining solar and waste heat into industrial processes requires detailed process modelling, with particular attention to guaranteeing an effective integration into existing industrial sites.

SINTEF has a portfolio of projects covering component and system design to integrate solar heating in industrial processes combined with waste heat recovery from the process itself.

The development of a heat supply for industrial processes by combining solar heat and waste heat recovery requires complex process modelling to cover many scenarios.

In one scenario, the available thermal energy could cover the industrial process's total heating demand. In this case, the main concerns are constant supply and energy storage if surplus heat is available. Energy storage could, for example, be based on the novel concepts of phase change materials (PCM) or the more conventional oil heat storage.

More frequently, the heat will not be enough to completely cover the process needs, regardless of the season and the clouds on a particular day. The solution, in this case, could be to integrate solar heating only in subprocesses at the site to reduce fuel consumption and consequently the site's carbon footprint.

The EU provides financial support and technical assistance to help those that are most affected by the move towards the green economy. This is called the Just Transition Mechanism. It will help mobilise at least €100 billion over the period 2021-2027 in the most affected regions.