The idea is as brilliant as it is simple.

“In principle, it works almost like a bicycle pump” says engineer and Project Manager Edgar Kvernevik at Kvernevik Engineering AS.

For the last two years his company has been working with Geir Arne Solheim, the founder of Havkraft AS in Norway, and the man who came up with the idea, to develop and build the wave power plant now installed in a former trawler/autoline vessel.

Then and now. The vessel as it once was, and today in its role as a small power plant. It is now anchored and generating electricity offshore Stadt. Havkraft AS aims to scale up the plant to enable it to produce hydrogen. Photo: Havkraft AS

But how do you get a fishing vessel to work like a gigantic bicycle pump?

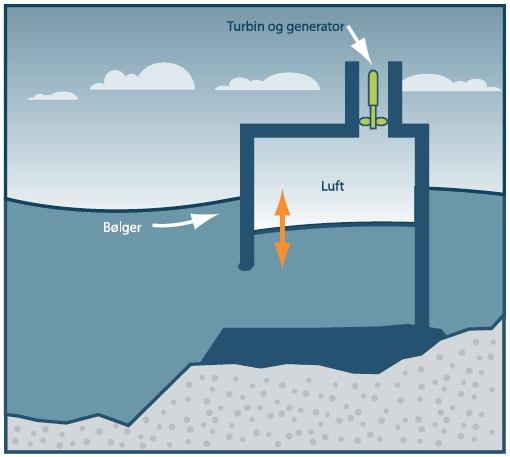

The makers have met this challenge by installing four large chambers in the vessel’s bow. As the waves strike the vessel, the water level in the chambers rises. This creates an increase in air pressure which in turn drives four turbines – one for each chamber. The pitch of the vessel also contributes by generating additional air pressure in the chambers when the wave height is large. The design of the chambers is such that they work in response to different wave heights, which means that the energy is exploited very effectively.

“The plant thus produces electricity with the help of what is called a fluctuating water column”, explains Kvernevik, who has spent much of his working life designing and building vessels. “All we have to do is to let the vessel swing at anchor in a part of the ocean with sufficient wave energy. Everything is designed to be remotely-controlled from onshore”, he says.

- Also read “Building a hybrid fishingboat”

New application of a tried and trusted principle

The company Havkraft AS, which came up with the original concept, is based in Raudeberg in Nordfjord, Norway. Solheim, the company’s founder, has been working here with wave energy for more than 15 years. The company is now receiving funding from Innovation Norway to help put the idea into practice.

The “fluctuating water column” concept is a tried and trusted approach. However, installing a wave energy plant inside a fishing vessel is something no-one has done before.

“This floating power plant has also been equipped with a special anchoring system which means that it is always facing into the incoming waves”, explains Kvernevik. “This ensures that the plant is in the optimal position at all times”, he says.

A fluctuating water column is enclosed in a partly-submerged hollow structure. The column is open below the water line and contains a pocket of air in its upper part. The water column rises and falls within the structure in response to wave movements. These movements cause pressure fluctuations which force air in and out of the surge chamber at the top of the structure. (Source: Fornybar.no) Illustration: Endre Bardal.

Full overview of energy production

But Havkraft AS is not alone. One of the organisations contributing to the project is MARINTEK, which has developed a mathematical model and run a number of simulations of the plant. This has provided developers with a better overall picture of how much energy can be extracted from the waves. The project has advanced on the basis of analyses, model experiments and full-scale simulations.

“The use of simulations and dynamic analyses, in combination with model experiments, has enabled us to avoid beating repeatedly around the bush using the standard approach of trying out different scales of model”, says Kvernevik. “This has saved us time and money. We now have a full-scale model constructed and installed”, he says.

The nominal capacity of the plant is 4 x 50kW – 200kW in total. MARINTEK’s computations indicate that the plant is capable of producing 320,000 kWh per year.

Advanced engineering

Even though the principle behind the plant is simple, there is a lot of advanced engineering installed on board.

None of the moving parts are in direct contact with salt water. In fact, the only moving parts are the turbines, which are installed above the vessel’s deck. Moreover, it is constructed so that it runs the same way regardless of whether the chambers are “inhaling” or “exhaling”.

The vessel is currently located offshore Stadtlandet, in an area where the company Stadt Wind AS has a renewable energy testing licence. This is one of three test sites in the Stadthavet area, which together comprise the so-called Stadt Test Area.

A study of an offshore wind farm (the 1080MW Stadtwind project, involving floating wind turbines) was previously carried out in the same area. The Norwegian Water Resources and Energy Directorate (NVE) subsequently declared the area as one of the few in Norway suitable for the installation of floating offshore wind farms. The annual average wind speed measured in the area is 11 m/s, which is higher than any other location in Norway, including the North Sea. This indicates that the area is clearly well suited to the exploitation of renewable energy from wind and waves, which is interesting because in the long-term, the project plans to look into the possibility of combining floating wave power plants with wind turbines.

Hydrogen production next

“We see this project as a three-stage rocket”, says Kvernevik.

“The first stage is to test the model we have just built to make sure that electricity generation can be carried out as planned. Next, a hydrogen production plant will be installed on board the vessel so that the electricity generated can be stored in the form of hydrogen gas. We have high hopes that hydrogen will be the car fuel of the future. Our aim is to work with others to produce hydrogen at a competitive price – based on an infinite resource and involving no harmful emissions”, says Kvernevik optimistically.

FACTS: The following organisations have taken part in the project:

The plant was built at Stadyard in Raudeberg. The company Smartmotor in Trondheim has supplied the power electronics which convert the electricity produced by the generators. Ulvesund Elektro in Deknepollen has supplied the electronics that enable the entire plant to be remotely-controlled from onshore. The turbines which produce the electricity were designed by Kvernevik Engineering, while Nyborg has manufactured the turbines themselves and their housings. OffTek has performed the calculations of the plant's operation and has conducted the model experiments. MARINTEK has developed the computational model of the plant, and further field tests at sea will contribute towards improving this model.

“The plan is then to construct a plant with a nominal capacity of 1000kW (1MW). We will do this by installing five production modules similar to the current plant either on a larger vessel or a custom-built barge. Finally, we will build a semi-submersible platform designed to carry a 4MW wave power plant with a 6MW wind turbine installed on top”, he says.

MARINTEK in Trondheim is one of the project partners which have contributed towards the development of the wave power plant.

“We have built a basic computational model of the plant”, says MARINTEK’s Jørgen Hals Todalshaug, a hydrodynamicist and an expert in wave energy. The project will now be running a series of field tests at sea which will provide Havkraft AS with experience of how the plant works under operational conditions.

The tests will also provide quantitative data that can be used to improve and calibrate the computational model, and thus improve its accuracy.