“The price of solar-generated electricity continues to plummet, and the technology is taking over as the least expensive form of energy in more and more parts of the world”, says solar cell researcher John Atle Bones at SINTEF.

“We’re at an economic tipping point that favours solar cell technology”, he says. “Good illustrations of this from the USA include the Berkeley Energy Group/EDF Renewable Energy project, which recently shut down a coal mine and established a solar park on the same site. In California, the authorities have recently decided to introduce roof-based solar panel standards for new housing”, explains Bones.

Perfecting raw material selection

Price reductions in increasingly more popular solar panels are the result of developments in both technology and production methods – and it is exactly this technology and its raw materials that Bones and his colleagues are looking into. SINTEF researchers now intend to use robots to enhance the quality of the end product.

Perfecting the manufacture of so-called monocrystalline silicon (the material that forms the basis of a solar cell’s ability to generate electricity) has been preoccupying the research community at SINTEF for many years. Researchers have now focused their attention and, more to the point, that of their sensors towards the important quartz crucible that plays one of the key roles in the manufacture of solar cells (see fact box).

The role of the quartz crucible in the manufacture of solar cells:

A quartz crucible is a bowl-like container, between 50 and 70 cm in diameter with walls about 1 cm thick. The quality of the crucible is very important. If it is inadequate, the end product will be unusable. The crucible is built up of different quartz layers that perform a variety of functions during the manufacturing process. It acts as a container used in the furnaces that melt silicon prior to the production of monocrystalline silicon. As part of this process, a so-called “seed” crystal is dipped into the molten silicon, and a large monocrystalline silicon crystal is then withdrawn from the melt. This crystal withdrawal process takes up to two days. The end product is an approximately two metre-long and 20 centimetre-wide crystal which in turn is used as the raw material for the manufacture of so-called silicon wafers. These wafers are then divided up to produce solar cells.

“The better the raw materials we have, the more efficient the solar cells will be, and this in turn will reduce the environmental footprint of the electricity the cells generate”, says Bones. “So it’s important that the quartz crucibles we use are of the highest quality. Currently, quality assurance of the crucibles is carried out by visual inspection, but this has its limitations”, says Bones, who is leading the project.

Robotic optics – yes please!

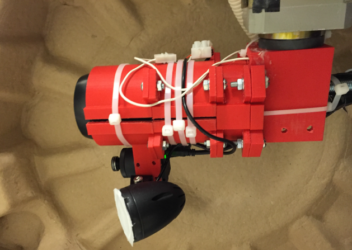

The robot has been developed by SINTEF researchers and a group of students at NTNU, and is based on a number of optical sensors that can detect much more than is visible to the human eye.

This dedicated sensor package has given the robot both super sight and the characteristics of a detective. Quartz crucibles are built up of different layers with varying structures that combine reflectivity and transparency. To reveal a crucible’s properties, faults and defects it is necessary, literally, to search in depth.

“Before we built this robot we studied crucibles in order to identify the connection between their quality and the properties of the monocrystalline silicon end product”, says Bones. “To do this we had to be quite brutal”, he says. “We applied what are quite simply called destructive methods. This means crushing, grinding up and dissolving the materials in chemicals. Subsequent analyses gave us clear indications as to the properties of the different layers that should make up a given crucible”, says Bones.

But now they have taught the robot to recognise defects in crucibles without so much as a grain of dust being destroyed in the process. SINTEF’ new robot enables a crucible to be guided through a rapid and very accurate sorting process before it is used in the melt furnace. Here it plays one of the main roles in the crystal withdrawal process that precedes wafer manufacture.

Eyes on stalks: This robot is equipped with a very special package of sensors combined with machine vision. This allows it to detect much more than is visible to the human eye. Photo: SINTEF.

“The crucibles are typically between 50 and 70 centimetres in diameter and weigh 10 kilograms”, says Bones. “It is thus important to be able to utilise them as optimally as possible”, he says. “Using a crucible with the wrong properties may result in having to re-melt the manufactured silicon”, he says.

Laser vision and sensors

Finding a single sensor that could do everything that the researchers wanted proved to be impossible. So they combined a selection of sensors and enabled them to communicate with each other. According to Bones, the confocal white light sensor is one of the most important included in this system.

It functions by responding to the different colours and corresponding wavelengths in the white light spectrum (see the illustration).

A confocal white light sensor is able to split white light by transmitting it through different lenses. The result is that the focal length is distributed across a specified number of points on the object, which together provide a light spectrum composed of different colours. When the light is reflected back to a spectrometer in the measuring instrument, the intensity of the wavelengths enables us to make an exact measurement of the distance to the object being inspected. Illustration: SINTEF.

Among other things, a high-resolution digital CCD camera is also included that can “see” at very detailed scales. This in turn is connected to a machine vision device that enables the system to identify small variations in materials that should not be there.

The robot then locates itself in the correct physical position.

“Among the things we’re measuring is the curvature and thickness of the quartz crucible, which is bowl-like in shape”, says Bones. “Here, the robot has to adjust its “eyes” at the correct angle for all the points it is programmed to inspect. This is made possible using several distance sensors and by carrying out calculations that permit the robot continuously to correct the track along which it moves”, he explains.

No problem in sharing

“It gives us extra pleasure to have succeeded in achieving this with limited funding – and the collaboration of NTNU students who have worked on this project as part of their Bachelor’s and Master’s degrees”, says Bones, who is now ready to share the analytical sensor technology with anyone who thinks they can put it to good use.

“What would be even better is if someone read this article and decided that’s just what I need for my project!”, he says. “Much of what we’ve achieved here is transferable to other processes and raw materials”, says Bones.

So, if you are one of those who believe that this technology may be useful to you, just call John Atle Bones at SINTEF.

Facts about the project:

Name: Crucible inspection robot

Duration: Started in 2014, currently ongoing

Participants: SINTEF and NTNU

Funding: Internally-funded project.

Results:

Automated sorting of quartz crucibles

Better data for specification of crucibles

More intelligent use of crucibles in the melt furnaces

Tailored smelting processes adapted to individual crucibles