“It’s a new approach to manufacturing battery electrodes”, says Researcher Tor Olav Sunde at SINTEF.

In 2019, Tesla paid about NOK 2 billion for the American company Maxwell Technologies just to get their hands on a similar technology, known in the industry as dry-processed electrodes.

As Sunde will tell you, the electrodes are the heart of any battery. They are made of metal foil with a thin coating of active chemical materials. Electrons flow as electricity when the ions move from one electrode to another. Batteries can be used in everything from torches to telephones and cars, as well as the major components of energy systems used for grid balancing.

Energy- and space-demanding production process

The problem is that electrode manufacture uses a lot of energy and takes up plenty of space. The process is also hazardous to both people and the environment.

“The active electrode material, through which the ions pass in and out, has to be mixed with additives”, explains Tor Olav Sunde. “This is necessary in order to ensure that the electrodes bind together and conduct the electricity”, he says.

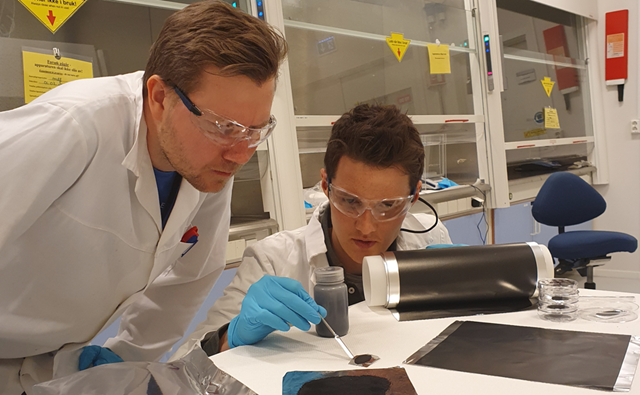

If you want to manufacture batteries, you need plenty of space and energy. SINTEF researcher Tor Olav Sunde (left) and Nikolai Helth Gaukås have discovered how to save on both. Photo: SINTEF Industry.

Sunde compares the process with that used when making pancakes. As well as flour, sugar is needed to taste, and eggs to hold the pancakes together. Milk is added to make sure that all the ingredients are mixed together.

The same principle applies when you manufacture electrodes. In order to mix the active chemical materials with the additives, they are all stirred together with a solvent to produce a wet mass, which is then coated onto the metal foil. Before the battery is assembled, the solvent has to be removed, and this is done by drying the electrode.

Environmentally hazardous solvents demand expensive HSE

“This process requires a lot of energy, and more than one third of the energy required to make a battery may be dedicated to this drying process”, says Sunde.

“So could this dry battery system be Elon Musk’s next big thing?”, he adds.

Not only are large volumes of energy needed to remove all the solvents, but the process also requires a lot of space. The drying ovens used to achieve fully dry electrodes have to be many tens of metres long. The process also takes time because the electrode material must be dried in a uniform and controlled way in order to prevent it from cracking.

“Moreover, the solvents commonly used can be very nasty”, says Sunde. “They are toxic to people and hazardous to the natural environment. You need massive systems and equipment to recover them and prevent them from being discharged. Massive amounts of HSE equipment have to be installed as part of the process, making it even more complex and expensive”, says Sunde.

Switching to ‘dry processing’

And so – to the solution. Sunde is ready with the hard facts about dry processing manufacture.

“We simply carry out the mixing process without using solvents. The active material and the additives are mixed dry”, he says.

The most difficult aspect is making the thin electrode coating. This is what SINTEF is researching into now. You can’t just mix a number of raw substances together and hope that things will turn out alright. If it had been as simple as that, someone would have found out long ago.

“We’ve now tested a number of different ways of doing this and have learned a great deal about what works and what doesn’t”, says Sunde. “We also need heat and pressure. We have to work with temperature and pressure in order to give the electrode its correct properties”, he says.

Energy efficiency is key

Spoiler alert! The researchers succeeded.

“The electrodes we’ve made so far are looking very good”, says Sunde. “When we test them in batteries, they appear to work just as well as those made using solvents. “We’re making excellent pancakes without milk!”, he says.

The result means massive energy and economic savings. There is some way to go before reaching the ultimate goal, which is to make the big battery plants less energy-demanding and more eco-friendly. In the meantime, SINTEF has succeeded in achieving small-scale dry processing in the laboratory. However, more work is needed before the process can be industrialised – both in terms of quality and scale of production.

“But we have the first results, and we’ve demonstrated that the process works”, says Tor Olav Sunde.

Now he’s on the lookout for opportunities to advance the technology.

The researchers are now in the process of getting their IP rights and patenting in order. When all that is completed, the next stage will be scientific publication.