Or 0.5% more for an avocado for a 35% reduction in emissions? Or 2% more in tolls to cross a bridge for a 70% reduction in emissions? SINTEF, NTNU and TU Delft have investigated the effect that implementing CCS in 10 different industries would have on the emissions and costs of nine products and services. The results showed that CO2 emissions could be significantly reduced at a marginal cost to the public.

“While more research is still needed, these results provide invaluable insight into the real cost and benefits of CCS on a societal level – not just on an industry level,” said Simon Roussanaly, research scientist at SINTEF Energy Research and lead author of the study.

This work was conducted in connection with the Norwegian CCS Research Centre (NCCS). The results have been published as a paper: “Putting the costs and benefits of carbon capture and storage into perspective: a multi-sector to multi-product analysis” in a recent edition of Progress in Energy.

Investigating the cost of CCS for the consumer

Cost has long been cited as a barrier to large-scale CCS implementation. However, these costs often reflect the impact of implementing CCS on the industrial facility, and not on the resulting product or service that would be sold to or used by the public.

In 2023, research from SINTEF and TU Delft demonstrated that implementing carbon capture and storage (CCS) in steel and cement production could have lowered the CO2 emissions associated with a bridge’s construction by 51% for at just a 1% increase in cost for the public.

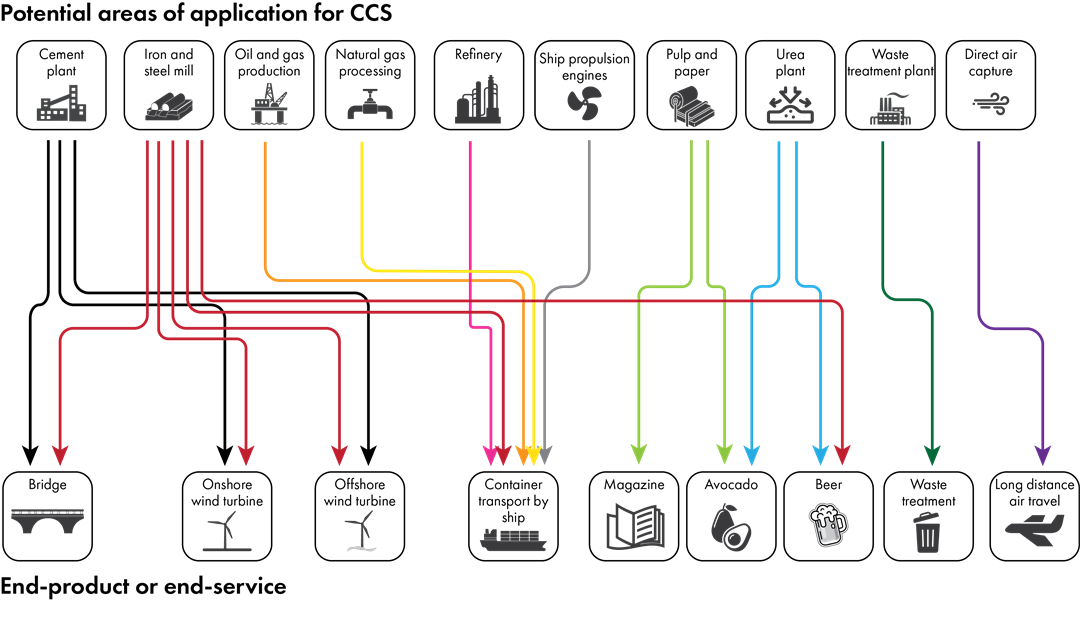

Now, a new study has sought to broaden this understanding by examining ten industrial areas with the potential for CCS implementation: a cement plant, an iron and steel mill, oil and gas production, natural gas processing, a refinery, ship propulsion engines, a pulp and paper mill, a urea plant, a waste treatment plant, and direct air capture.

The study then investigated the impact of CCS in terms of emission reduction and cost increase on nine end products and services: bridges, onshore wind turbines, offshore wind turbines, container transport by ship, magazines, avocados, beer, waste treatment, and long-distance air travel.

A 50-80% reduction in emissions for a 0.5-2% increase in cost

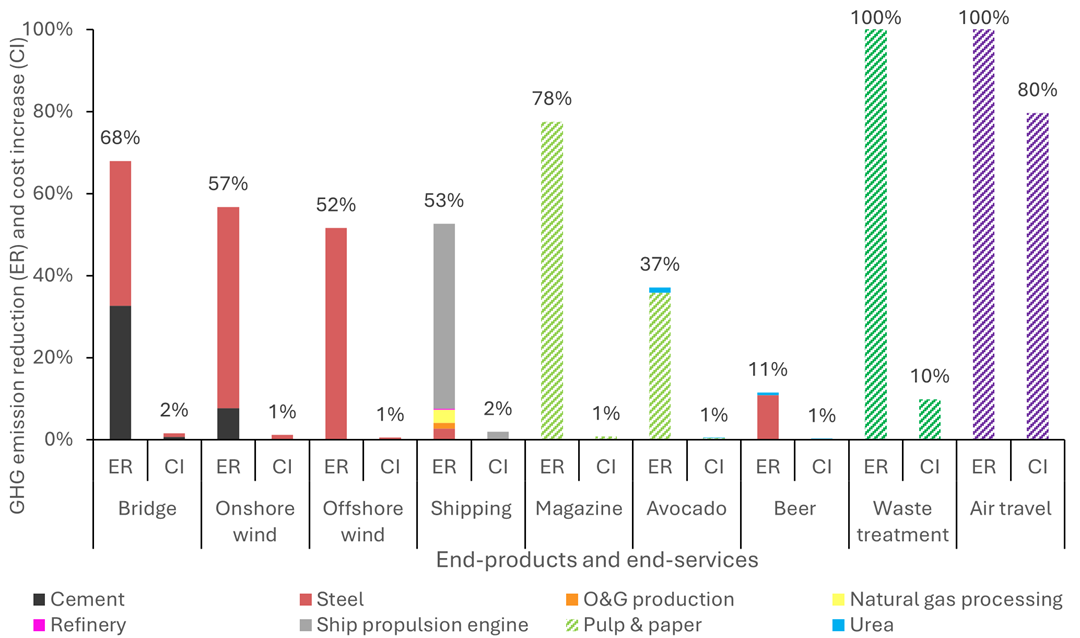

The results show that five of these end products and services (bridge, onshore wind, offshore wind, shipping and magazine) could reduce the emissions associated with their production by 50-80% for between 0.5-2% cost increase.

While the potential emissions reductions would be less for an avocado and a beer, 35% and 10%, respectively, this would be for a marginal cost increase of 0.3% and 0.2%, respectively. Implementing CCS on a waste treatment plant could eliminate the associated emissions in their entirety, but at a slightly higher cost increase of 10% (corresponding to €20 per year for a family of four).

Long-distance air travel was the only outlier. While capturing CO2 directly from the air had the potential to compensate for 100% of the associated emissions, it comes at a significant cost increase for the consumer: 80%.

From potential to reality: first CO2 capture on cement facility due to start in 2025

These results indicate that the increased costs associated with CCS implementation in these industries could be covered by a minimal increase in service charges, cost of the product itself, or taxes. However, financial support will still be needed to cover the higher costs of early movers.

One such early mover is Heidelberg Materials, who are due to start capturing CO2 from their cement plant in Brevik, Norway in 2025 as part of Longship: the Norwegian government’s first, full-scale CCS value chain initiative. The project is jointly financed by Heidelberg Materials and the state of Norway.

“For society as a whole, we need to see where we can get the largest CO2 cuts per Euro/Dollar. 50% of inherent carbon in a reference building originates from concrete, so if you want to cut the really large CO2 volumes, the obvious answer is CCS cement – this is where we get the most bang for the buck,” said Pia Prestmo, head of public affairs at Heidelberg Materials.

While this work provides valuable insight into the real costs and benefits of CCS, which will hopefully soon be realised by industries such as Heidelberg Materials, CCS is not the only decarbonisation technology available. As such, it would be interesting to go further to understand how CCS can be combined with other technologies to achieve net-zero emission products and services without breaking the bank.