Microbiological fertilizers are one of a large variety of products that are needed to make the agriculture industry in Europe more sustainable.

Over the past year, SINTEF has been working in a joint project with the Lithuanian company NANDO. NANDO is one of the leading agro-biotechnology companies in Northern Europe that develops and manufactures high added-value microbiological products and chemical additives for agriculture and industry. Until now, part of their production of microbiological fertilizers has been outsourced to third countries. The company wanted to establish an automated industrial fermentation line for making microbiological fertilizers in Lithuania.

Improved product yields of microorganisms for bio-fertilization

SINTEF contributed to the project with bioprocess optimization to improve the cultivation process for the microorganisms that are basis for NANDO's fertilizers. SINTEF holds leading competence within the design and optimalization of biotechnological processes, such as fermentation technology. Our work supports the shift to greener and more sustainable industries and is used for the production and application of biopharmaceuticals, enzymes, ingredients, biopolymers and materials for human medicine, aquaculture, food and feed, and other sectors.

For the NANDO project, SINTEF has optimized the growth media for the bacterial strains and contributed to the design of a fed-batch process to obtain higher cell densities.

– In the lab we tested several strains and a wide range of different growth media components, with the aim to simplify the medium, reduce costs and increase the productivity, says research scientist at SINTEF, Deni Koseto, and adds:

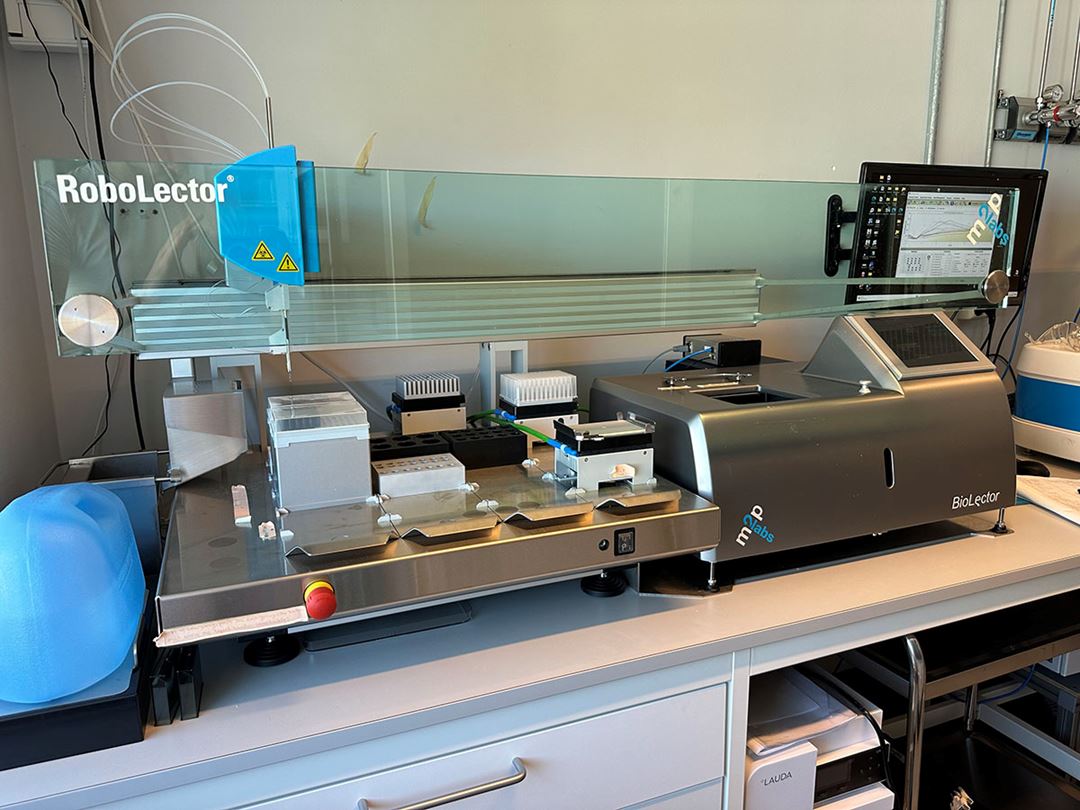

– At SINTEF we have state-of-the-art laboratories with equipment that gives us the possibility to cover every aspect of bioprocesses. Our micro-fermentor platform is ideal for this type of work, making it possible to simultaneously assess a high number of strains and medium components.

During the project, NANDO’s production has been fully moved into the NANDO production centre in Lithuania. The new fully automated industrial fermentation line consists of upstream and downstream processing units, such as fed-batch cultivations and purifications.

The project has been financially supported by the Norway Grants (Norwegian Financial Mechanism 2014-2021 Programme Business Development, Innovations and SMEs' ICT focus area).