With the Net-Zero Industry Act, the European Commission has set a target of capturing and storing 50 million tonnes of CO2 per year by 2030 in the EU – increasing to around 200 million tonnes per year in 2040 and 250 million tonnes in 2050.

– To reach such annual volumes, we must drill and put into operation a minimum of 30 - 50 new CO2 storage wells in the years to come, with an injection rate of 0.7-1.5 million tonnes per year, says Research Manager at SINTEF Ane Lothe.

Norway has been at the forefront of geological CO2 storage for a long time. As early as the mid-1980s, researchers at SINTEF in Trondheim developed the idea of storing carbon dioxide in water-filled pore spaces. Statoil, at that time, started using the technology as early as 1996 and began CO2 storage in water-filled sandstone layers above the Sleipner gas field. This has been a great success, and today, Equinor is injecting an average of 850,000 tonnes of CO2 per year in the Sleipner project and an average of 610,000 tonnes in the Snøhvit project.

– SINTEF has led the research on CO2 storage and has helped to ensure that first Equinor, and now many other Norwegian operators, have a strong focus and knowledge on the subject. In addition to supporting the industry with field-scale studies, SINTEF conducts both theoretical and practical research, from small-scale laboratory experiments to larger-scale field experiments," says Research Manager Peder Eliasson.

Although Norway was an early adopter, we must not forget the hare from Aesos’s fables, who was so pleased with himself that he took a nap before the race with the tortoise was finished.

– 1.5 million tonnes per year may seem like large amounts, but to meet the 2-degree target in the Paris Agreement and the Net-Zero Industry Act, much larger amounts of CO2 must be captured and stored in water-filled reservoirs or depleted gas fields, says Ane Lothe.

A rapid increase in the number of storage licenses has been posted and awarded, both in Norway and in other countries.

– To develop so many new licenses and transition from studies to investment and industrial operations, Norway needs the help from researchers, industry and suppliers to ensure that CO2 storage is carried out as safely and cost-effectively as possible.

Safety is essential in full-scale CO2 storage. Extensive feasibility studies, analyses and knowledge of reservoirs and the formation, are crucial to eliminate various types of risks, such as leakage from the subsurface.

– Both during the injection and up to 20 years afterwards, it is essential that the storage operation is closely monitored to confirm that the CO2 stays in the storage complex and moves as expected. This is a regulatory requirement, but also of the highest interest for operators who want safe, predictable and efficient operation, says Peder Eliasson.

Open research facilities at Svelvik

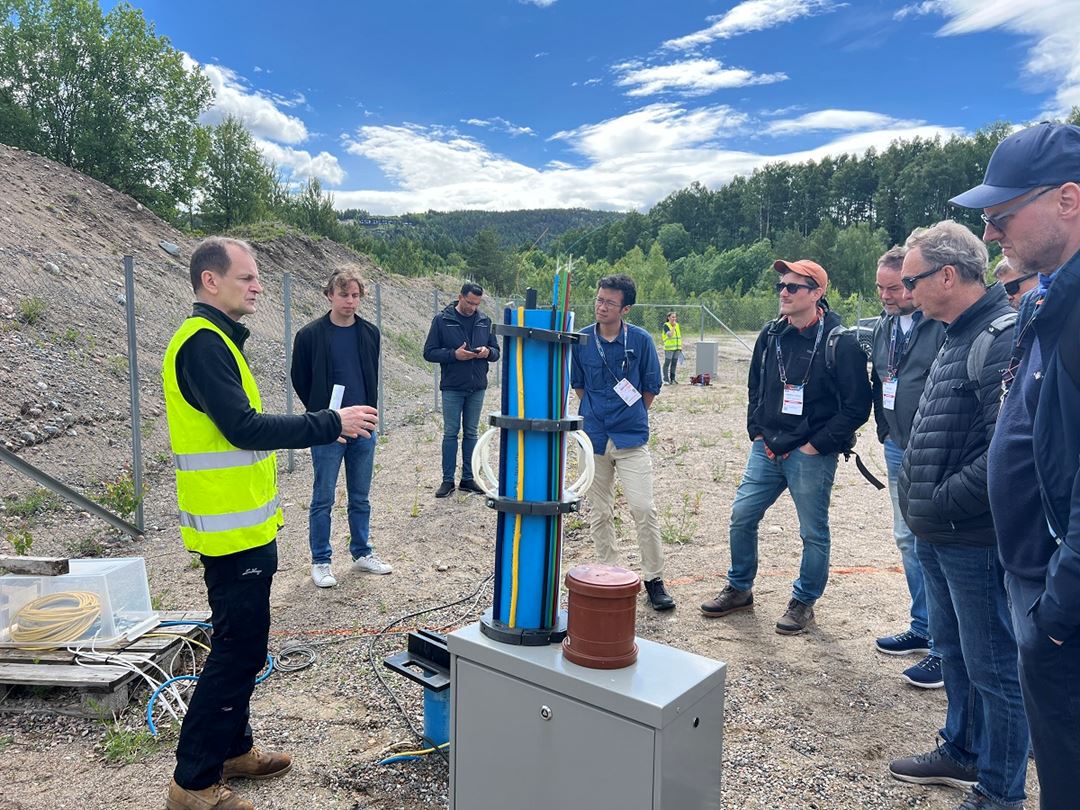

Just outside Svelvik, SINTEF operates the ECCSEL CO2 Field Lab, which is a small-scale field laboratory on land for rapid and cost-effective development and testing of technology for monitoring future CO2 wells. In 2023 and 2024, the lab is used for, among other things, experimental studies as part of the LINCCS project to develop methods for monitoring potential leaks along injection wells.

Due to its size, its controls on the external environment, and its potential for repeated experiments, the field laboratory provides excellent opportunities to carry out a wide range of studies of geophysical monitoring methods and equipment.

Anyone, from the industry and suppliers to researchers and students, can come and test new research methods at Svelvik CO2 Field Lab. The lab is an open research infrastructure and part of the European collaboration ECCSEL.

Although monitoring is essential, and in the long run cost-saving by making operations predictable and avoiding unexpected events, detailed geophysical measurements can be expensive in themselves. A lot of research is therefore dedicated to identify the most effective methods to investigate, confirm and collect the precise information required.

– The Svelvik CO2 Field Lab operates on a different scale than offshore underground storage, with injection at 65 m depth, compared to 800 m depth at Sleipner. Nevertheless, new effectively studies testing innovative monitoring instruments and methods for interpreting collected data. Controlled studies on leakage upwards in the subsurface and check what is being measured, the amount of CO2 and how fast the gas is migrating, can be carried out.

If Norway wants to maintain its leadership in CO2 storage and avoid the fate of the hare in the fable, more research on safe and cost-effective methods for large-scale storage is necessary. Utilizing the field lab at Svelvik and similar research facilities will be essential in the coming years.