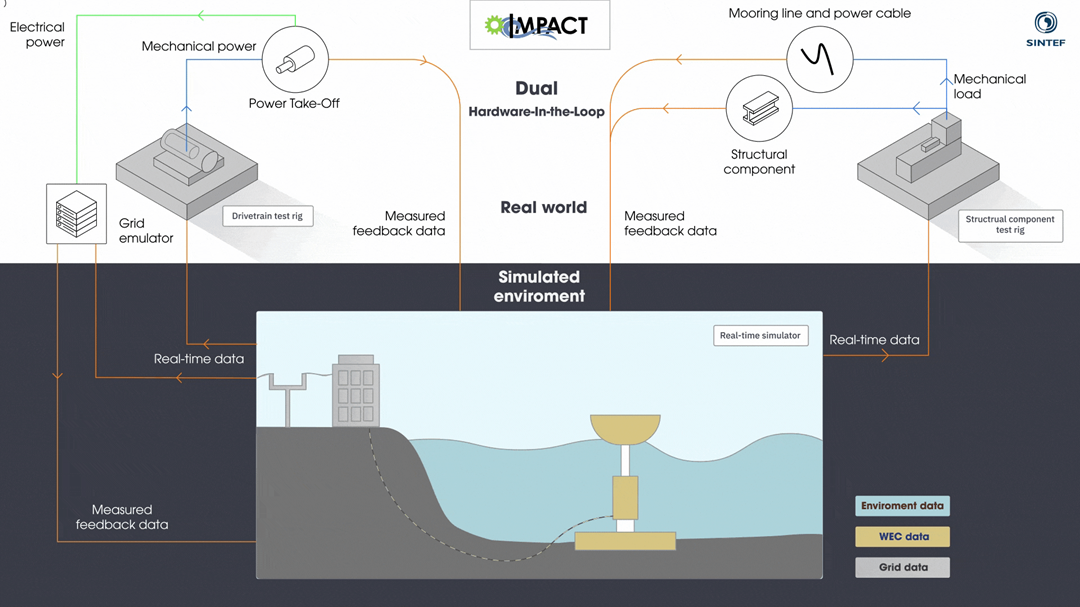

This dual hardware-in-the-loop (Dual HIL) platform tests different parts of the WEC simultaneously, providing a holistic picture of how the various components behave and impact each other. As such, this approach increases confidence in WEC deployment, while reducing both time and expenses connected with testing.

Rig testing is key for WEC development

This work was performed through the Horizon 2020 project, IMPACT (Innovative Methods for Wave Energy Pathways Acceleration through Novel Criteria and Test Rigs).

While WEC development has advanced significantly in recent years, several significant obstacles to its commercialisation remain; in particular, ensuring the device’s reliability and the performance of the power take-off.

Rig testing enables us to address these challenges before the WEC undergoes operational tests in the sea, increasing its chances of success.

With this in mind, the IMPACT project members have developed and demonstrated a dual hardware-in-the-loop testing platform, consisting of two independent rigs: a drivetrain rig and a structural components rig. This testing platform takes advantage of traditional hardware-in-the-loop (HIL) testing, while also considering dependencies between the subsystems.

SINTEF has played a key role throughout the project

SINTEF has been active throughout the entire project, leading three of the eight work packages and playing a fundamental role in three others.

In particular, SINTEF has been key in the development of the two test rigs.

The drivetrain test rig was originally constructed as part of the concluded EU project IMAGINE, but further upgraded through IMPACT to test linear and rotary PTOs for different types of WECs, and to emulate different grid conditions and the point of common coupling.

SINTEF Energy Research assisted with characterising the rig, which included acquiring and verifying results, which were postprocessed using MATLAB. They also started to verify the setup for the dual HIL approach and recommended some small adjustments.

The structural components test rig was designed and constructed in IMPACT, to test the integrity of components under mechanical stress, such as the mooring system, dynamic power cables, joints and seals. This rig has already been used to test the belt of Carnegie Clean Energy’s CETO 6 wave energy converter.

SINTEF Ocean created a digital twin of this rig to enable the collection of even more valuable data about its performance. SINTEF Ocean also oversaw the testing procedures for both rigs, and conducted the necessary risk assessments.

A holistic approach to WEC development

In the Dual HIL, these two rigs run simultaneously, targeting different parts of the WEC. This data is fed back into a real-time simulator, and used collectively, together with environmental data, to influence the next round of tests for both rigs.

This approach only produces a more thorough understanding of how the WEC behaves in different environmental conditions as a whole, but also enables possible failures resulting from the interaction between different subsystems to be anticipated.

The IMPACT platform will now continue as part of the Structural Wave Energy Equipment Test (SWEET) Lab in Deruta, Italy.

About IMPACT

IMPACT received funding from the European Union’s Horizon 2020 research and innovation programme, under grant agreement no. 101007071. The project ran for three and a half years from 2021 to 2024. In addition to SINTEF Energy Research and SINTEF Ocean, the consortium consisted of VGA in Italy (the project coordinator), Yavin Four Consultants in Portugal, and University College Cork (SFI MaREI) in Ireland.

More information about the project, its partners and its results can be found on the project website.