In the EU, the glass and aluminum industries annually emit approximately 21.5 million tonnes of CO2 equivalents. The glass industry must be completely carbon neutral by 2050, according to the EU Commission.

Glass production is energy intensive with its high temperatures and also emits CO2 emissions and other harmful emissions such as nitrogen oxides (NOx). The glass furnaces used in industry have had natural gas and electricity as their most important energy sources. The large furnaces, which have a lifespan of about 12-15 years, will take time to replace. Therefore, it is urgent to start innovation.

Similar conditions apply to the aluminum industry. When various aluminum products are to be made, aluminum is also melted in furnaces and with processes that in many ways resemble those for glassmaking. This energy-intensive production also emits large greenhouse gas emissions, and there are several possibilities for replacing fossil heat sources with hydrogen along the entire value chain.

– A radical redesign and advanced heat recovery systems have been seen as a solution, but even with this, the maximum increase in energy efficiency would not be more than 10-15 percent and not enough to meet the decarbonization goals," says Research Manager at SINTEF Energy, Chiara Caccamo.

Replacing natural gas with hydrogen

This is where hydrogen as an energy source comes in. Instead of natural gas, we can use sustainable hydrogen, which would mean that we only get water and not greenhouse gas emissions when we burn the gas.

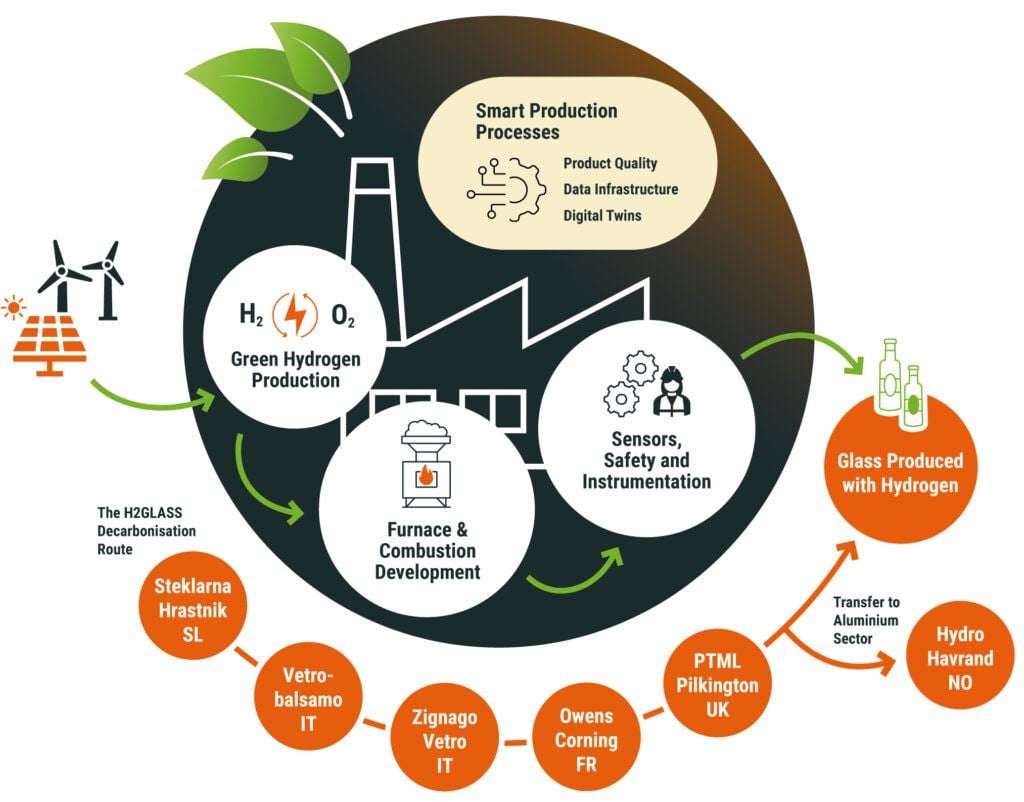

Together with European industry partners, the EU-funded project H2Glass will develop a new technology platform for the combustion of hydrogen at glass and aluminum producers.

– If the project succeeds, an emission reduction of approximately 80 percent will be possible, says Chiara Caccamo.

– The goal is to develop the technologies that glass manufacturers need to realize the goal of 100 percent hydrogen combustion in their production facilities, as well as to ensure the necessary production quality and safety.

The technology platform is built on the development of specific furnace systems with improved heat transfer efficiency and minimal emissions, adaptation of factory infrastructure to H2 processes, and optimization of the use of both fossil fuels and H2.

This will be tested through five pilots at partners in the glass and aluminum sectors to demonstrate potential transferability to other energy-intensive industries. Hydrogen will be supplied by a mobile electrolysis unit co-financed by the industrial partners.

Digital twins will be used for risk-based maintenance, optimised production and control of the combustion system.

A test campaign has been conducted to investigate how the furnace can be modified and for incorporating hydrogen into the process. The test investigated the possibility of producing glass by burning H2, how to control the process and burn H2 effectively.

– We aimed to achieve more stable and reliable combustion emissions results, understand the impact of H2 on glass temperatures and melt, including foam formation in the furnace. We conducted emissions measurements and collected samples of produced glass articles for laboratory analysis to examine how they were affected on such as colour and water content, says Giuseppe Fragapane - Research Manager at SINTEF Manufacturing.

How the technology will be scaled up

In order to reach the zero-emission targets, manufacturers and other energy-intensive industries need to adopt innovative technologies that allow reducing their carbon footprint.

- We are employing a unified methodology for a comprehensive analysis of environmental, techno-economic and societal impacts resulting from the hydrogen solutions. The results obtained in the pilots will be upscaled for a proper understanding of potential consequences of the further implementation of the project solutions in other energy-intensive sectors, says Research Scientist at SINTEF Industry, Thiago Silva.

The first step is to define the scope and potential benefits of the technology at pilot scale. From a techno-economic perspective, hydrogen value chains are then being identified to find efficient alternatives for supply. Economic studies assess the additional capital expenditures and operating costs for the factories with hydrogen combustion. Life Cycle Assessments (LCA) then compare the environmental consequences of solutions with hydrogen supply against the current fossil-based situation across all life cycle stages. Finally, the societal impacts are analyzed, such as job creation. Based on the analyses and findings the project will provide recommendations for decision-makers.

Positive gains for the glass and aluminum industry

The glass and aluminum industry in the EU employs more than 400,000 people in Europe and generates more than €3.5 billion. The innovations generated by the project will potentially create 10,000 new jobs and unlock €1-5 billion in revenue for the deployment of glass technology, triggering over €17 billion in investment and 200,000 new green hydrogen jobs.

SINTEF Energy Research (ER), coordinator of the project, SINTEF Manufacturing (Man) and SINTEF Industry (Ind) contribute to the project with their research knowledge. SINTEF ER leads the work on combustion technology and the work package focusing on safety and risk management. SINTEF Man targets the industrial demonstrators and testing campaigns, whereas SINTEF Ind is responsible for the scientific foundation for the transferability to aluminum production and leads the work package on how the project developments can be scaled up and their potential environmental, social and economic impacts.