Aluminium is the most widely used non-ferrous metal in the world with application going from the packaging industry to airplane parts and power lines. It is found as a compound and it is commonly extracted from bauxite. Norway is the biggest producer of primary aluminium in Western Europe and 80 % of it is exported . About 1.2 million tonnes of aluminium were produced in Norway in 2014 . The production of aluminium is a highly energy demanding process: energy constitutes 20-40 % of the production costs .

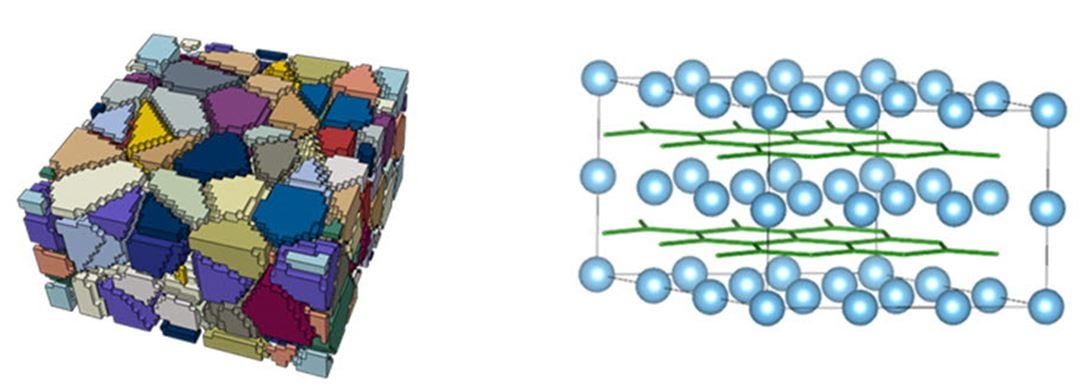

This project aims at understanding the degradation mechanism due to sodium diffusion that decreases the lifetime of one of the main component of the electrolysis cell, the "cathode block". The success of the project will possibly allow improvements in the choice of materials in the electrolysis cell and in the cell design and therefore imply energy savings.

The cooperation between research groups in SINTEF with well-established competences within Al electrolysis process, finite element/numerical analyses, material modelling and fracture prediction, multiscale modelling, and diffusion modelling is the core of the project. The main idea is to bring together such competences to create a multiscale methodology for studying material degradation for materials and components in the electrolysis cell. Both theoretical and numerical calculations (e.g. DFT calculations and FE analyses) and laboratory experiments measuring Na vapour infiltration are part of the project activities.

The project is funded by "Norsk Hydro Fond for SINTEF" where both the Research Council of Norway and Hydro are members of the board.

Related projects:

- CARMA: https://www.sintef.no/en/projects/carma-reactivity-of-carbon-and-refractory-material/

- ROP: https://www.sintef.no/en/projects/rop-knowledge-basis-for-repair-contingency-of-pipe/

- HIPP: https://www.ntnu.edu/kt/research/hipp

- SIMLab : https://www.ntnu.edu/simlab

- CASA: https://www.ntnu.edu/casa

- NextDrill: https://www.sintef.no/en/projects/next-drill-numerical-experimental-technology-platf/

Contacts:

Micol Pezzotta, Mobil: 982 83 962, Epost:

Zhaohui Wang, Mobil: 462 49 405, Epost: