Geothermal energy has high cost related to exploration and reservoir mapping and thereby high upfront risk. However, successful geothermal projects have lower levelized cost of electricity (LCOE) than some solar and wind energy projects. Equinor has an ambition to investigate possibilities for harvesting geothermal power from hydrothermal HT reservoirs by producing supercritical fluid (reservoir temperature about 450-550°C and pressure up to 300 bars). In this condition, the geothermal fluid has a much higher energy (enthalpy) than steam and liquid extracted with conventional geothermal wells, thus potentially multiplying the electricity output by a factor of 5 to 10 and hence lowering LCOE of geothermal projects.

However, the aggressive fluids and high temperatures encountered in these geothermal reservoirs are tough challenges for any materials and structures to sustain during the operation lifetime of at least 20 years. The casing system, which is a composite structure with a steel casing and cement sheath on its outside, needs to be designed to protect the integrity of the geothermal well, and protecting the shallow environment against contamination, under the expected harsh conditions. An improper design may lead to severe failure in casing, e.g. by a) mechanical buckling, b) tensile failure (in threaded connection or cross section), c) hydrogen embrittlement, and d) corrosion, and consequently result to loss of the well, as happened in the past Icelandic Deep Drilling Project No. 1 (IDDP1).

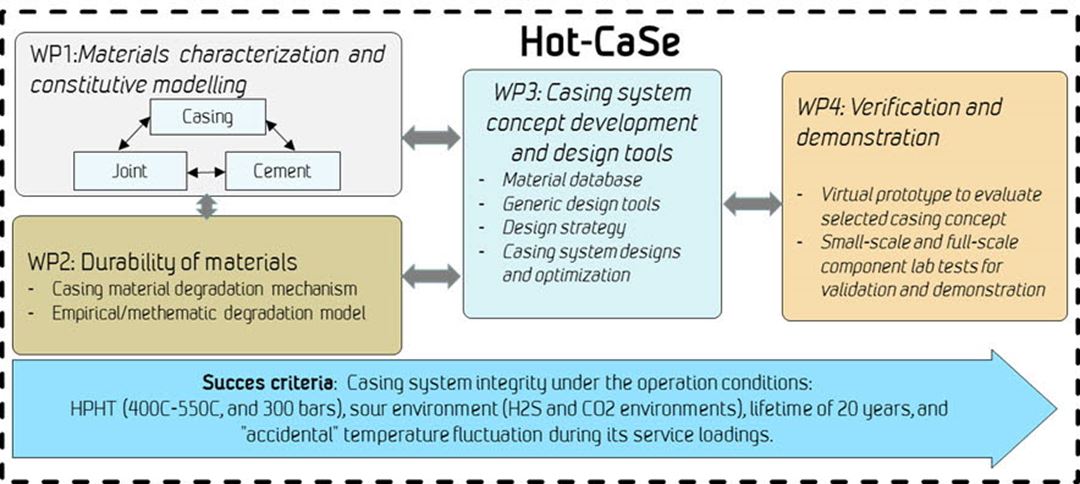

The project has an important mission in itself to solve these challenges related to the well construction. To achieve that, the research activities will be carried out in four coupled work packages as illustrated in following Figure: WP1: Mechanical characterization and constitutive modelling, WP2: Durability of materials, WP3: Casing system concept development and design tools, WP4: Verification and demonstration.

At the initiation of the project, a three-day workshop, gathering personnel resources from the involved companies, R&D institutions and other national/international experts, was organized to freely scout for innovative solutions for cost-effective and reliable casing systems. The project is developing Design Tools to evaluate the identified casing alternatives, by exploring combinations of mainly pre-existing technologies. The functional and mechanical performance of selected well completions solutions will be tested and verified under the mentioned super HT condition, both in physical laboratory and numerical simulations with help of data computers. The successful HotCaSe project is going to contribute to access a new dimension in geothermal energy utilization, thus having a significant impact on both society and environment.

HotCaSe is a four-year Innovation project (from 2017 to 2021) with total budget of 30 MNOK, led by Equinor and backed up by the Research Council of Norway (ENERGIX Programme) together with national and international industries & research partners: SINTEF (No), Elkem (No), Norcem (No), IMERYS Aluminates (Fr), Curistec (Fr), HS ORKA (IS), OR (IS) and ISOR (IS). SINTEF has mandate to manage the project on behalf of Equinor.

The project will also create arenas that gather national and international actors along the industrial value chain, thus strengthening the partnership to further mature and industrialize the project results