Safety and lightweight solutions are main focuses in today's automotive industry. Multi-material and lightweight structural components, such as aluminium-steel, in vehicle system with high-performance is deemed necessary to have great contribution to reduction of greenhouse gas emissions. The key to success is a combination of multi-material product design, optimal material selection and cost effective manufacturing processes for high volume production.

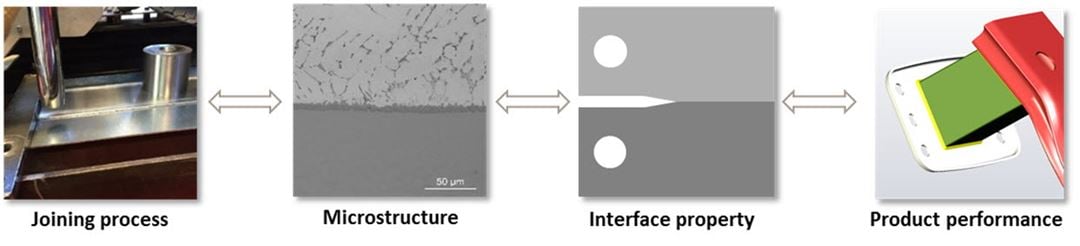

The project will develop new principles for design and material selection for automotive structural components and crash management systems, as well as new innovative joining technologies for joining of aluminium to steel. The project will aim to achieve a measurable weight reduction (5-10%) for 2-3 automotive components while keeping or improving specific structural requirements. Successful implementation of the innovations will significantly contribute to lightweight solutions not just for automotive industry but also other industries and sectors, e.g., transportation industry, marine industry, green shipping as well as oil and gas industry.

OPTIMALS is an Innovation Project for the Industrial Sector (IPN) within RCN BIA program with a total budget of 23.2 MNOK. The project is supported by RCN and industry partners Benteler Automotive, Hydro Aluminium and HyBond. SINTEF Materials and Chemistry is the research partner, and will contribute to the development of cold metal transfer (CMT) welding process for joining aluminium to steel, material and component characterization as well as numerical simulations. SINTEF laboratories involved in the OPTIMALS project include: Welding Lab, Characterization Lab and Materials Testing Lab.

The project is supportet by the Inudtry partneres and The Reseach Council of Norway.