Lifetime extension of offshore structures is urgent for ensuring the development and optimal management of Norwegian petroleum resources within an environmentally sustainable framework. Enhanced oil recovery from existing oil fields and tie-in from new fields rely on extended use of existing structures. The use of existing infrastructure is not only energy efficient with reduced carbon footprint but is also regarded as the only economically viable solution for development of many small fields. The physical degradation and aging of offshore structures and components are main challenges for structural life extension. Aged components often need necessary (and expensive) repair and maintenance to ensure that the structural integrity is still retained throughout the extended life.

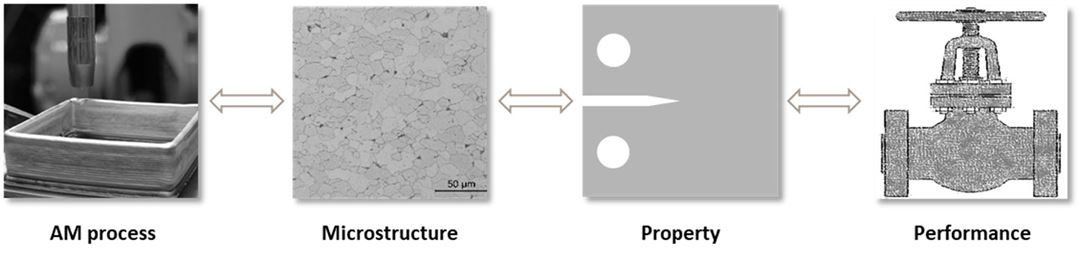

The AMRREX project will introduce two emerging additive manufacturing (AM) technologies, wire and arc additive manufacturing (WAAM) and laser metal deposition (LMD), for "on-site" and "on-time" repair and refurbishment of damaged components in order to secure and extend lifetime of structures. The key R&D challenge in this project is to establish the relationship between AM processes, material properties and performance of repaired components.

The AMRREX project is an Innovation Project for the Industrial Sector (IPN) within RCN PETETROMAKS2 program with a total budget of 25 MNOK. The project is supported by RCN and industry partners Westad Industri, Equinor, Vitec and Nordic Additive Manufacturing (NAM). SINTEF Industry and SINTEF Manufacturing are the research partners. Both institutes will contribute to the development of WAAM and LMD processes, robot control, material characterization as well as numerical simulations.