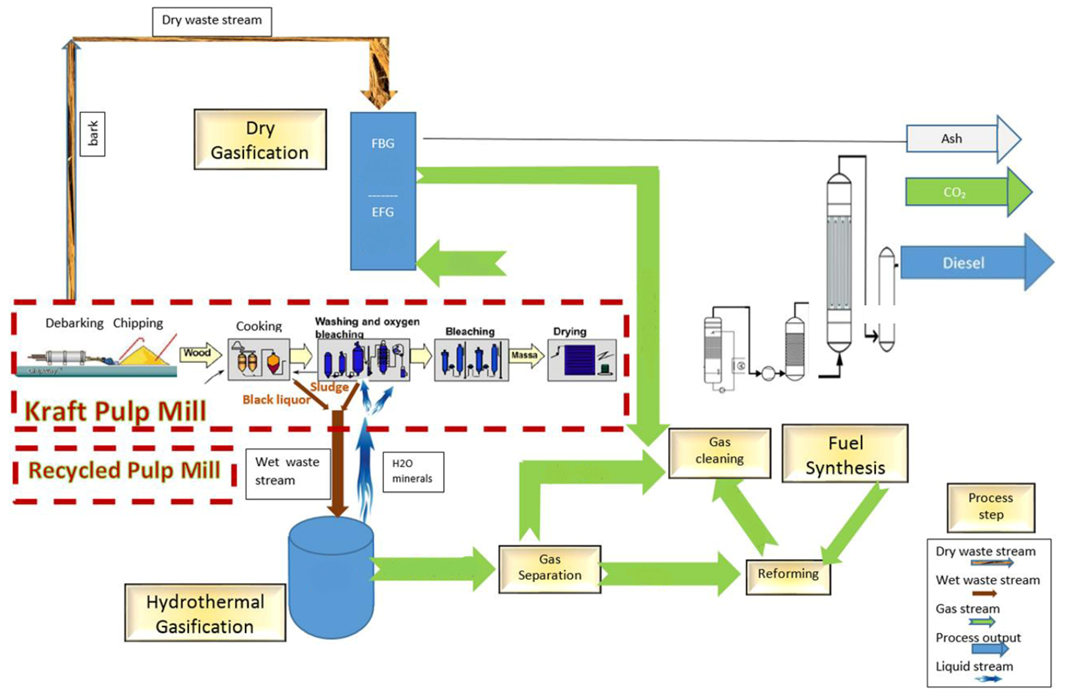

For the PULP&FUEL project, we have chosen to study the integration of the full process on a pulp mill. The developed process will take advantage of low to negative value wet and dry resources on a paper mill to add value to the overall process. The yield of biofuels will be significantly increased to 28% compared to a classic approach that would only yield 18%. The PULP&FUEL final objective is to produce biofuels below 1 €/L without having a negative impact on the existing operations of the pulp mill.

To achieve these goals a team of 10 partners, leaders in their field, from 4 EU-member states, will join efforts. To this end, we have defined five ambitious specific objectives:

- Improve the efficiency of the dry gasification process from 70 to 80%

- Improve the carbon conversion of the wet gasification process to above 90%

- Improve fuel synthesis to obtain carbon efficiencies above 50% (state of the art 45%)

- Integration of the full process and synergy between dry and wet gasification

- Integrated assessments will show that biofuels can be produced below 1 €/L

The PULP&FUEL project addresses the topic "liquid diesel- and gasoline-like biofuels from biogenic residues and wastes through either chemical, biochemical and thermochemical pathways, or a combination of them" of the LC-SC3-RES-21-2018 call.

Project consortium:

- CEA Liten, France (Coordinator)

- SINTEF

- EPFL, Switzerland

- RICE ETC, Sweden

- IVL, Sweden

- Grenoble INP, France

- SOFRESID, France

- Fibre Excellence, France

- Top Industrie, France

- Absiskey, France

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 818011.

For more information about the project, see http://pulpandfuel.eu/

https://cordis.europa.eu/project/rcn/218227/factsheet/en