Silicones production is the most valuable application of silicon in chemical industry. This market is growing quickly (~5% per year) and will reach US$ 20 Billion by 2022. Elkem Silicon Products strategy is based on specialisation by developing new, high-performance, specialty products for each market segment.

HECSI research project focuses on the silicone value chain and aims at understanding coking in the chemical reactor (first step to form silicon precursors) and supporting the development of dedicated silicon material to reduce or prevent coking.

In the silicones value chain market, silicon providers are facing three simultaneous challenges related to the productivity of the chemical reactor: (i) the process is continuous (silicon powder continuously injected in the reactor) which requires good material chemistry stability (ii) complex parallel reactions of different types of methyl-chlorosilanes which requires specific elements and phases to promote the desired reaction and (iii) presence of adverse reactions that can slow down or even kill the catalysed process mainly by carbon deposition.

Over the last decades the first two points have drawn much attention, leading to improved silicon material properties. Nevertheless, the third point is now becoming increasingly important and needs to be addressed in order to further improve the productivity. The challenge in reducing carbon formation is linked with the complexity of the chemical reactions occurring in the Fluidized Bed Reactor (FBR).

The new premium silicon grade for silicones production will have two main characteristics:

- High Reliability: ensuring homogeneous material composition and intermetallic phase content

- High Reactivity: ensuring that the material contains not only the right promoters but also inhibitors for the detrimental reactions.

SINTEF will contribute to this project by providing atom scale simulations to understand the chemical mechanisms leading to coking. SINTEF will also support data analysis and the design of new silicon products.

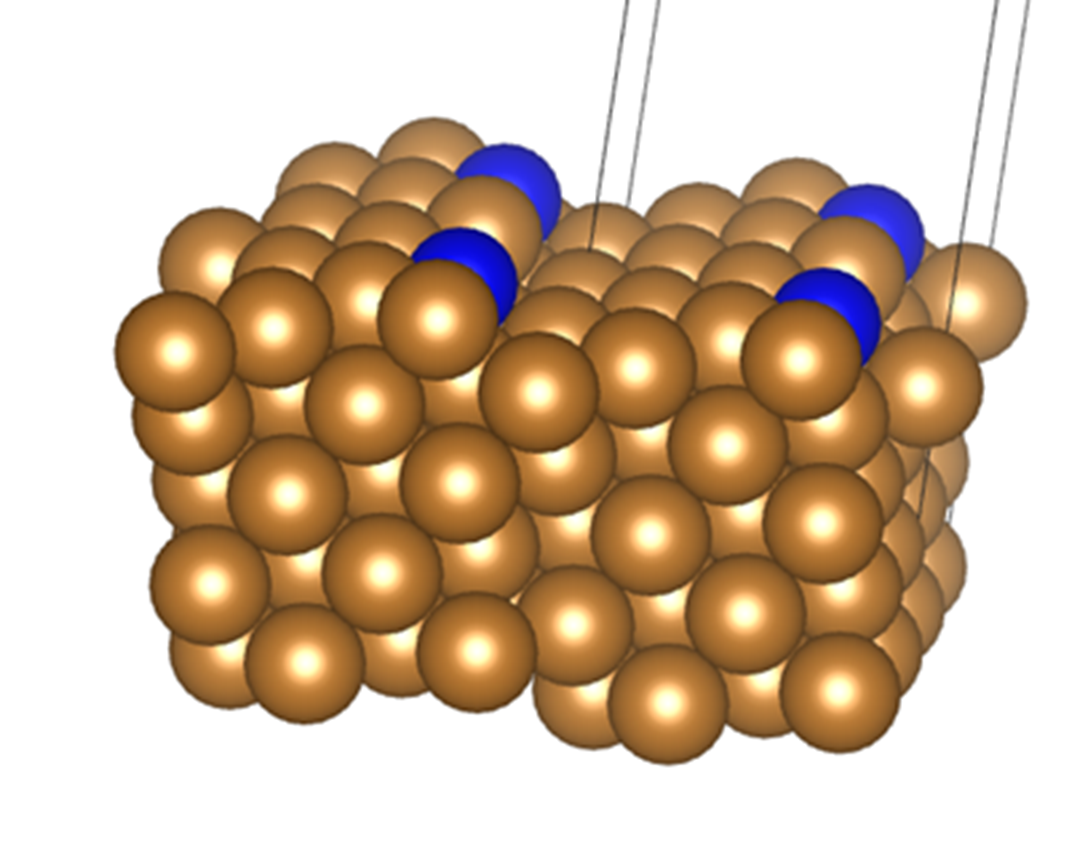

Relevant surface models will be adopted to investigate the effect of small surface alterations on reactions relevant for coke formation. Density Functional Theory will be used to calculate reaction and activation energies. Choice of models will be made based on data from experimental results.

Partners: Elkem Silicon Products, NTNU.International collaboration with Elkem Silicones (France). This project is funded by the Research Council of Norway.