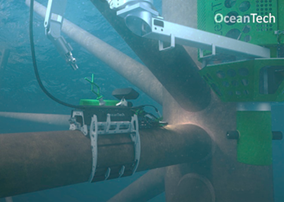

To achieve the goal of the project, OceanTech Innovation, together with SINTEF and partners DNV GL and ConocoPhillips, will develop an automated inspection robot for detection of small fatigue cracks in steel substructures. Calculations of the remaining service life can then be made. The robot must operate in the so-called splash zone and tolerate varying conditions, large forces from the elements and marine entangling. SINTEF contributes expertise in NDT (non-destructive testing) techniques, machine learning, 3D camera technology and robot technology.

ANDWIS

Big jacket structures on the Norwegian shelf are now reaching the limit of their estimated service life, but new discoveries and improved production methods make prolonged operations desirable. There is therefore an increasing need for underwater condition control for offshore steel platforms, but also in connection with offshore wind and fish farming facilities.

Contact person

Key facts

Project duration

2020 - 2023

Financing

OceanTech Innovation has received support through the PETROMAKS2 program for an innovation project where the goal is to carry out condition control quickly, safely, and reliably in the splash zone under the platform deck.

Cooperation partners

ConocoPhillips and DNV GL