Hydro Aluminium has a total of 27 melting and holding aluminium furnaces located in 5 different casthouses in Norway. Surveys of the fuel consumption and the energy efficiency for the different furnaces show large variations, over time for each furnace and between different furnaces.

By understanding and controlling these variations, the potential for reduction in fuel, cost and CO2 emissions might be realized. The FurnAl project will therefore develop numerical models and monitoring techniques for casthouse furnaces for improved energy efficiency. This includes detailed numerical models of the furnace process and 'digital twins' / 'Maintenance Predictor'.

The detailed models will be used to achieve better understandings about the root causes and mechanisms for the large variations in energy efficiency for the different furnaces and for assessment of new and improved technologies and operations. The 'digital twins' / 'Maintenance Predictor' will utilise monitored data for combustion gases and temperature in the furnace, for early warning of wrong furnace behaviour and initiation of correct maintenance procedure with respect to infiltration of cold air or poor combustion.

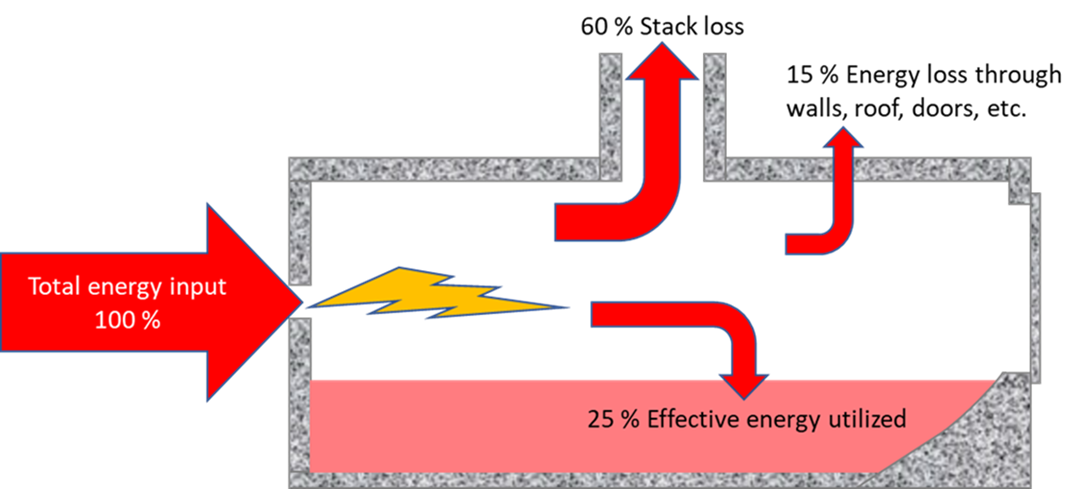

The project will contribute to the development and implementation of high efficiency Aluminium smelting and holding furnaces in Hydro's casthouses and help facilitate a 10 - 20 percent improvement in the energy efficiency for the best benchmark furnaces.

The FurnAl project is an Innovation Project for the Industrial sector (IPN) financed through Norwegian Research Council's ENERGYX program, with the partners Hydro Aluminium AS, NEO Monitors, Linde Gas AS, Gränges AB and SINTEF AS. SINTEF contributes with development and use of detailed modelling of the furnaces and development of the 'digital twin' / 'maintenance predictor'.