For power utilities, transformer failures are costly incidents that require expensive replacement work and may result in fires, explosions and significant collateral damage. Such failures are also costly for society causing potentially harmful outages and reduced security of energy supply.

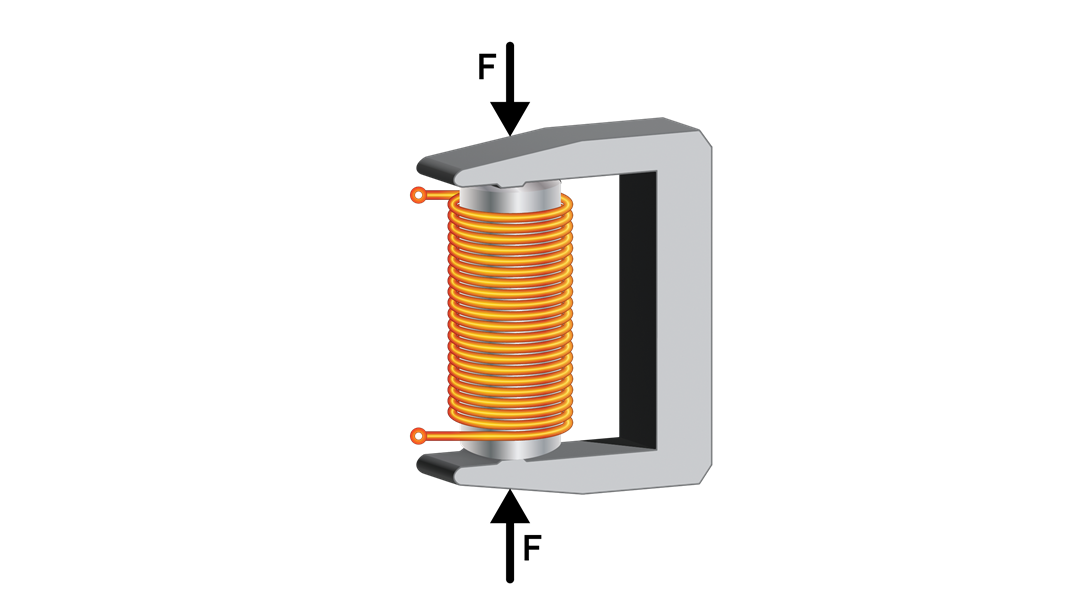

Mechanical deformation of transformer windings due to large electromagnetic forces during short circuit events is already a major cause for destructive transformer failures. This trend is likely to become more severe in upcoming years due to increased intermittent supply from renewable energy sources and heavy load cycling from e.g. high-powered charging facilities, which inevitably lead to new transformer operation schedules characterized by more frequent starts and stops, rapid power ramping, and an increased number of short-time overload periods. In DynaLoad, we address three specific challenges to combat this development: 1) Fundamental material research on improved mechanical endurance of winding insulation, 2) Modelling of the thermo-mechanical impact of rapid dynamic loading on transformer windings, and 3) Sensor-based condition monitoring of transformers in service.

DynaLoad will through experiments and modelling contribute essential knowledge regarding the performance of transformer winding insulation materials and the design of transformers operating under new dynamic load patterns in the future flexible power grid. Combined with real-life sensor data, these results will pave the way for increased sensor-based condition monitoring of transformers, to prevent costly failures and allow more precise estimates of transformer life expectancy for cost-efficient reinvestment plans in the existing transformer fleet.