The ICARUS project aims to turn this waste into valuable secondary raw materials.

The project unites 18 European partners to develop innovative methods for refining secondary raw materials from silicon PV manufacturing. Current production generates significant waste, including silicon kerf, graphite, and silica. ICARUS aims to transform this waste into valuable resources, potentially unlocking 3.5 million tons of silicon, 700,000 tons of silica, and 480,000 tons of graphite by 2027.

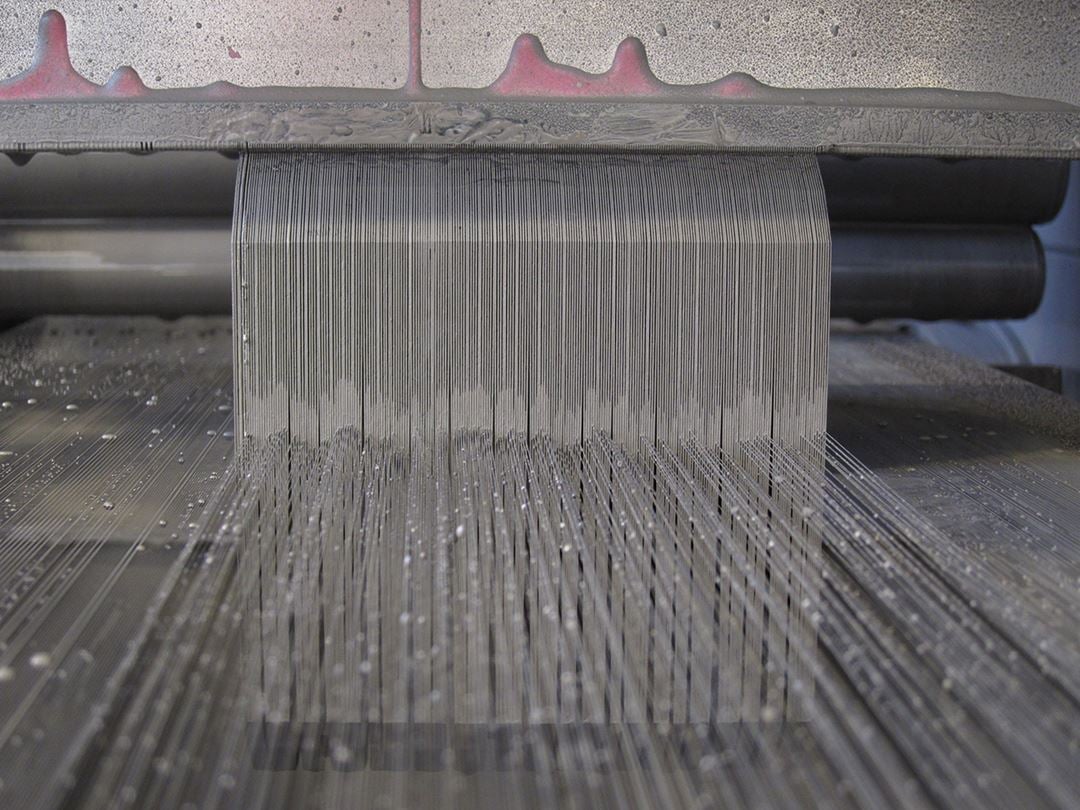

The project ICARUS focuses on four key industrial pilot technologies to recover and refine these materials. Purified silicon can be reintroduced into PV production through two methods: compacting dried silicon powder into “cold granules” or melting it into “hot granules.” A low-cost chemical process is also being developed to convert silicon kerf into green hydrogen, silicate, and silica by reacting it with sodium hydroxide under controlled conditions.

Beyond silicon kerf, ICARUS addresses waste from silica crucibles and graphite parts used in silicon ingot production. These high-purity materials are currently landfilled or downcycled. The project proposes recycling them through carbothermic reduction of quartz to produce metallurgical-grade silicon, later refined to solar-grade. This process replaces primary raw materials like carbon black and high-purity quartz with graphite and silica waste, making silicon production more sustainable.

Please read about the ICARUS project in "pv magazine"

Video