BE-sTrONG - Towards the future of sustainable concrete constructions in marine environments

Work Packages

The focus of R&D work is on:

- adaptation of advanced material solutions for environmentally friendly concrete,

- documentation of material robustness and performance tests acc.to national supplement to NS EN 206, and lifetime predictions,

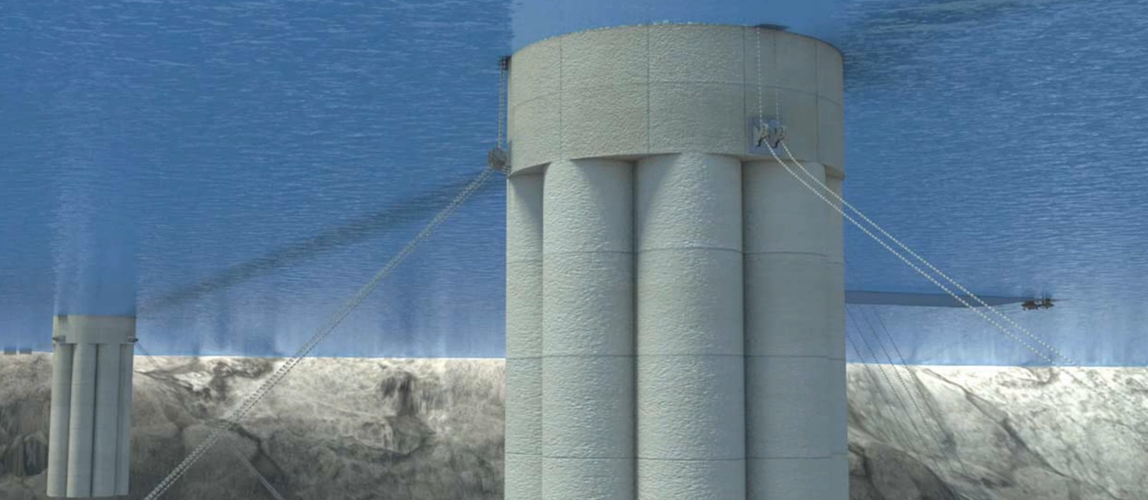

- verification/demonstration of prototypes through long-term exposure in relevant marine environment,

- documentation/certification of environmental performance.

Popular science summary of progress in BE-sTrONG innovation at project month 30:

The purpose of using advanced additives (TSS) in concrete is to compensate for the effect of reduced cement content in concrete and maintain durability. In H1, various TSS in selected binders were screened using a simplified test procedure applied to mortar recipes which yielded in a series of promising concrete compositions (M1.1, Q4/2022). This work resulted in recommended TSS and dosages for concrete recipes with binders provided by the cement manufacturers (M1.2, Q2/2023). Those concrete blends were investigated during profound performance testing in H2 showing that specific material combinations are needed to satisfy the requirement for early compressive strength (B55) and needed concrete resistance. A designated lab-scale program was therefore carried out at the manufacture site where the basic R&D results were verified with improved and up-scaled concrete blends (M2.1, Q1/2024) highlighting four promising concrete recipes to continue with. These mixtures were then first produced in lab-scale and characterized for robust performance in slip-casting before full-scale production with the four BE-sTrONG recipes could be started in summer 2024. In this final phase of material development, these recipes were optimized for intended fresh properties and the blends were transferred to mold boxes specially designed for the concrete beams (prototypes) equipped with dense steel reinforcement mesh and partially instrumented with sensors. This was an important step forward towards the field exposure in Austefjorden from September 2024 (H3). The monitoring protocol for the BE-sTrONG prototypes (M3.1, Q4/2023) foresees data recording and sampling for chloride analyzes over a longer period. In parallel, accelerated performance tests are carried out with small-sized concrete samples originated from the full-scale production to gain insight into selected material properties in short-term, as input to assess revision of existing standard requirements (DNV-ST-C502, M4.2, Q2/2024) in H4.

In the milestone report M4.1 (Q2/2023), the climate footprint of the environmentally friendly binders was evaluated that the cement suppliers brought into the project. Calculations of the CO2 footprint of selected concrete recipes from H2 show that it is feasible with the optimized industrial BE-sTrONG recipes (full-scale production) to achieve 30% reduction compared to the current industry reference for low-carbon concrete (B55; Low-carbon A; NB37/2024).

BE-sTrONG will show that the use of advanced TSS is increasing the durability of new concrete solutions, enabling to design and carry out future constructions in a marine environment with significantly reduced CO2 emissions, and reducing the resources required for maintenance and repair during the construction's planned lifetime.