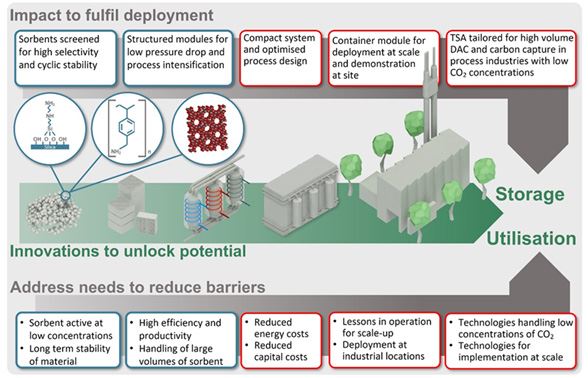

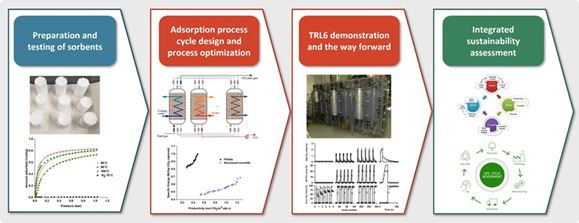

The technology will be demonstrated at TRL6 level for both the Direct Air Capture (DAC) case and for CO2 capture from the emissions of a glass plant by temperature swing adsorption using structured sorbents. The project involves screening and structuring of sorbents, process modelling and optimization, design and construction of a pilot unit, TRL6 demonstration at two different sites, techno-economic analysis, life cycle assessment and social assessment, as well as exploitation activities including commercialization and scalability.

The 2021 United Nations Climate Change Conference (COP26 Glasgow) confirmed that to limit the temperature increase to 1.5 °C above pre-industrial levels, global carbon dioxide emissions must be cut by 45 % by 2030 relative to the 2010 level and to net zero by midcentury. Reaching this target requires significant reduction of CO2 emissions and further development of negative-emission technologies, such as DAC, to cut atmospheric concentrations. In addition, there is also a need to advance technologies that can effectively handle flue gases with low CO2 concentrations, since the cumulated effect of low-concentration CO2 emitters is significant.

The main challenges of low-concentration CO2 capture are the high costs and energy requirements. Due to this, there is currently no capture technology available for industries with low CO2 concentrations in their off gas. To reach the climate goals, technologies for capture of low-concentration CO2, including both capture from air by DAC and from industries with low CO2 concentrations in their off gas, need to be implemented at large scale.

In SENSATION, reduction in the energy demand and the cost will be achieved through optimization of both the adsorbent used in the capture technology, as well as optimization of the process configuration through structured adsorbents for a low pressure drop and intensified capture cycle. Further, SENSATION puts great emphasis on the fact that the technology needs to be scalable, and thereby accelerate the time to market and contribute to a significant CO2 reduction by 2030.

Partners in the project: SINTEF, TNO, Corning, HyGear, IFEU, Removr, TotalEnergies and Freija

Total budget: 4.12 M€

SENSATION is funded through the CETPartnership (Clean Energy Transition Partnership) 2022 Joint Call