With the results, a techno-economic study will be carried out for large scale implementation in industry processes.

On the road to a more energy efficient industry, it is necessary to develop flexible technologies for excess heat recovery and storage. Specifically, recovery of excess heat generated at 120-300 °C needs high attention given the few technologies that can enable efficient and sustainable solutions.

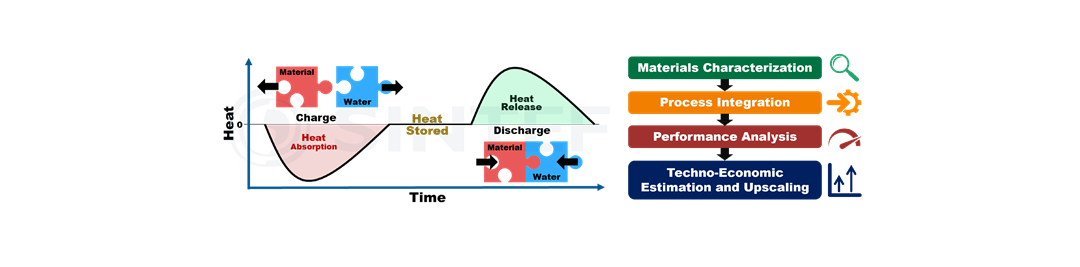

Water-sorption thermochemical energy storage (TCES) systems have potential as a flexible, compact, and sustainable solution to this, however the technology readiness level is still low. Compared to storage media such as phase change materials, PCMs, TCES offers the advantage of loss-free, long-term (up to weeks or even months) storage at room temperature, and an energy density several times that of PCMs.

Nowadays, research on TCES focus mainly on material properties at very low quantities, without further analysis of their behaviour at lab scale; or in development of reactors designed for one specific TCES material. The scarceness of lab scale validation of material properties needs to be overcome to advance TCES towards industrial uptake. Potential compounds with reaction temperatures in the excess heat range, such as MgSO4, are barely studied at lab scale.

Through lab scale characterisation of selected materials, we aim to overcome the crucial next step towards industrial use by performance analysis of candidate materials under relevant conditions at lab scale and study the path for further upscaling and integration. One advantage of TCES is the potential for economic upscaling, as storage tanks and recirculation rate of the material can be easily upscaled to enable an improved heat storage capacity without big modifications in the reactor (the costly part).

The first objective of ITChES will be materials selection by thermo-chemical analysis of potential candidates for excess heat recovery. Based on this, potential industrial processes will be reviewed as candidates for implementation, which will provide necessary experimental condition inputs to the laboratory study.

The second objective will consist in experimental performance analysis of selected materials in an existing lab-scale reactor, whose results will contribute to develop an integration and techno-economic study of an upscaled SA-TCES system for selected industrial processes.

The concept of ITChES, as a part of FME HighEFF, addresses the HighEFF goals of reduced energy consumption and CO2 emissions through several pathways:

- Allowing for an increasing share of renewable and intermittent energy sources in the energy mix by decoupling energy production and consumption in time.

- Saving waste heat by providing a means of affordable decoupling of industrial excess heat and its utilization, e.g. in steam processes.

- Peak shaving allows auxiliary equipment such as heat pumps to operate on full/optimal rather than partial load.