SINTEF has early identified data science and AI as key strategic areas for today’s research activities and enforces its application through several internal project initiatives and providing support tools.

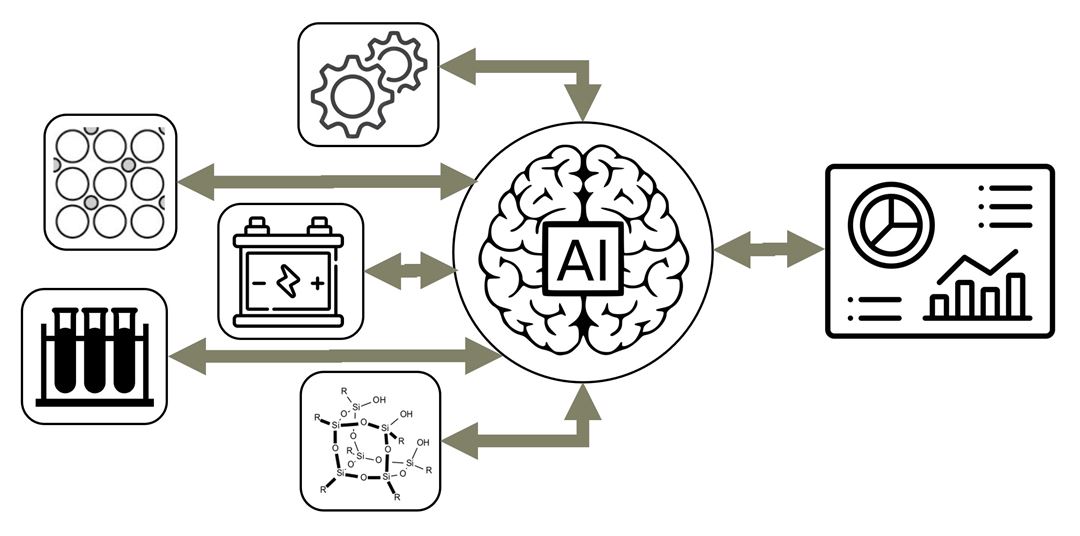

In this project, a common platform for implementing a sharable workflow of AI tools for different research areas of materials and process development will be established. Based on commonly developed templates domain experts are trained to customise case specific workflows. Six showcases will be demonstrated using the platform, including identification of new materials and production processes, real-time process optimization, sequence-data analysis and generative structure reconstruction. The project involves all the departments at SINTEF industry and two research groups at SINTEF digital. The output of this project is used to train SINTEF researchers and external customers to apply machine learning algorithms to R&D data in a wide range of technology domains.

The specific cases are:

- Identification of hybrid materials and electrode candidates

- Efficient and accurate multiscale simulation of aluminum and ferroalloy fabrication

- Autonomous optimization of lab-scale experiments

- Real-time anomaly detection and interpretation of drilling operations

- The application of AI tools in biotechnology research

- 3D generation of electrode material structures for battery/fuel cell development

Links

- Login internal pages