BioCarbUpgrade

BioCarbUpgrade - Upgrading biocarbon for sustainable metallurgical industries

BioCarbUpgrade - Upgrading biocarbon for sustainable metallurgical industries

Sustainable wood stoves through stove, building integration and value chain optimisation

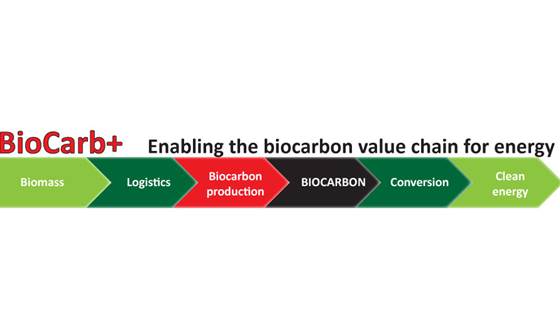

In the project BioCarb+ 2014-17, a huge effort was made towards studying the biocarbon value chain and its different value chain elements with respect to improvement possibilities while satisfying end-user demands.

In November 2018, the European ARBAHEAT consortium launched a research project to investigate the conversion of the ENGIE Ultra-SuperCritical coal-fired Rotterdam power plant into a biomass-fired heat and power plant.

Biomass to energy (BtE) and waste to energy (WtE) plants in Norway need to comply with stricter emission limits and/or adjust to tighter profit margins, and EU have implemented a further reduction of emission limits from medium (scale) combustion...

Clean and efficient wood stoves through improved batch combustion models and CFD modelling approaches

The overall objective of BioCarb+ is development of new strategies for use of low-grade biomass, pulpwood and energy wood resources for biocarbon (BC) production for raw material for industrial applications (reduction agent / metallurgical coke) and...

New solutions and technologies for heating of buildings with low heating demand: Stable heat release and distribution from batch combustion of wood.

STable OPerating conditions for biomass combustion plants

KRAV is a research project within combined heat and power production from biomass.