SURFER - Supporting Uptake of Renewables with Flexible Electrolysers for Resilient energy systems

SURFER will support Europe’s energy transition by creating more resilient, decarbonised energy systems by advancing hydrogen electrolysers.

SURFER will support Europe’s energy transition by creating more resilient, decarbonised energy systems by advancing hydrogen electrolysers.

BioClima project is a groundbreaking joint EU-China collaboration initiative that enhances how we monitor biodiversity and climate change by combining artificial intelligence with ground-based and satellite data.

SOLARIS drives Europe’s energy transition by optimizing resource efficiency and solar energy sustainability across the entire lifecycle of photovoltaics.

Carbon-negative pressurized hydrogen production from waste using an energy efficient protonic membrane reformer.

The Mecalo project will use hydrogen to convert CO2 emissions from metal production into a raw material that can be returned to the value chain. This way, the production of critical raw materials like silicon and manganese can be made CO2-neutral...

The main objective of the project is to develop food ingredients and products based on innovative processing of cultivated brown algae.

The APOLLO project is set to forge a circular system, intertwining traditional recycling practices with future manufacturing and recycling processes for Photovoltaic (PV) waste modules.

The main objective of COMPAS is to develop a compact, inexpensive, and ultrasensitive PIC sensing platform (PSP) for air and water monitoring, relying on the co-integration of light source, detectors, and electronic IC for on-chip signal processing.

FUEL-UP aims to accelerate the deployment of advanced biofuels made from fast pyrolysis by de-risking and upscaling all the steps until fuel use. Allowing new routes to biofuels entering the market, which will mean an at least 80% emissions reduction...

The project improves industrial energy efficiency by integrating geothermal energy with high-temperature heat pumps and heat-driven cooling systems, ensuring environmental sustainability and operational flexibility.

ICO2NIC will couple developments in polymer membrane-based CO2 capture technology with a novel Gas Diffusion electrochemical cell for CO2 to formic acid conversion. Valorisation of formic acid via innovative biological processing routes will deliver...

The project aims to design, validate and build an integrated prototype demonstrator that utilizes an immersion cooling system in combination with new, highly efficient materials and systems for long-term thermal energy storage.

Complying with the Paris Climate Agreement will mean that the EU economy of 2050 is set to be mineral/metal intensive, rather than one based on fossil fuels.

The HICCUPS project proposes a resource efficient solution to convert biogenic CO2 emissions from wastewater treatment plants into bio-based polymers for the packaging industry.

Carbon capture from syngas to Single Cell Protein (SCP) and use as fish feed ingredient

CAPTUS aims to demonstrate sustainable and cost-effective pathways to produce high added-value renewable energy carriers from the carbon emissions of energy intensive industries.

CAPTUS will demonstrate sustainable and cost-effective pathways to produce high-added value RECs in EIIs by valorizing industrial carbon emissions and integrating renewable electricity surplus.

AURORA will further develop and demonstrate advanced CO2 capture technologies to the point of commercial deployment.

Physics and data-based battery management by multi-domain digital twins (BATMAX) sets out to pave the way for advanced next generation adaptable battery management systems capable of fulfilling the needs and requirements of various mobile and...

The project aims to address the need for flexible and efficient manufacturing that produces zero waste and high-quality products.

The FIREFLY project supports the sustainable evolution of the catalyst-based chemical industry towards its electrification and reduced third-party dependence on metals and fossil energy.

Advancing hydrogen (H2) technologies and smart production systems to decarbonise the glass and aluminium sectors

NEXTCELL’S overarching goal is to provide a new Li-Ion cell generation for both high capacity and high voltage applications by developing and validating a ground-breaking gellified cell concept, integrating several innovations at the material level...

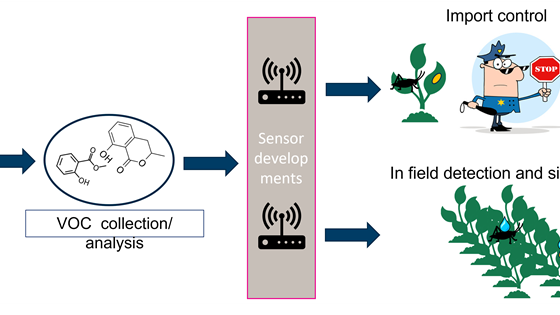

The main objective of PurPest is to control serious plant pests during import and to manage them in the field by developing a unique concept enabling pest detection in a timely and non-invasive manner. One goal is to increase the inspection of plants...

Refinery integration, scale-up and certification for aviation and marine biofuels production.

The Sure2Coat project will demonstrate the benefit of surface treatments with respect to corrosion protection and to improved heat transfer properties.

The SUSTAINCELL project aims at supporting the European industry in the development of the next generation electrolyser and fuel cell technologies (both low and high temperature) by developing a sustainable European supply chain of materials...

Structural reliable offshore floating pv solution integrating circular concrete floating breakwater.

Innovative and sustainable high voltage Li -ion cells for next generation (EV) batteries (IntelLiGent) will pave the way to sustainable European generation 3B Li-ion batteries with increased energy density (≥ 350 Wh/kg) by an optimized high voltage...

Digital and innovative mine of the future

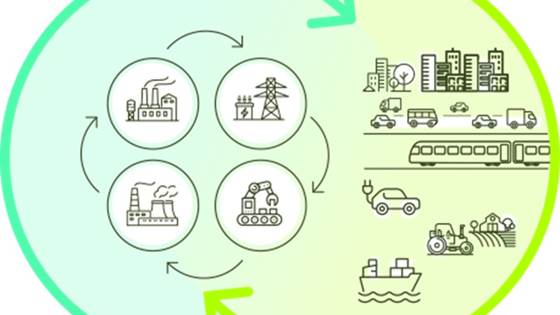

TRINEFLEX is a toolkit for Energy Intensive Industries: a service managing the digital aspects and the flexibility and sustainability transition of industrial processes.

The ultimate solution to the climate change is the total replacement of fossil fuels, not only as energy vectors but also as the primary carbon source for most of the material goods society needs.

Flex4Fact aims to increase renewable penetration in the industry energy mix, overcoming the challenges of fluctuations in prices and availability. It will do so by exploiting plant production flexibility, energy stream optimisation and local...

H4C Europe aims to accelerate the transition to industrial symbiosis, industrial-urban symbiosis, and circular economy by promoting what is called Hubs4Circularities.

Achieving Europe’s climate-neutral objectives will fundamentally depend on our ability to develop clean energy and mobility solutions in the most sustainable way.

The COMPASS project's main goal is to create and test new drilling and completion technologies to boost the number of economically viable high-temperature geothermal wells.

Territorial and regional demonstrations of systemic solutions of key value chains and their replication to deploy circular economy

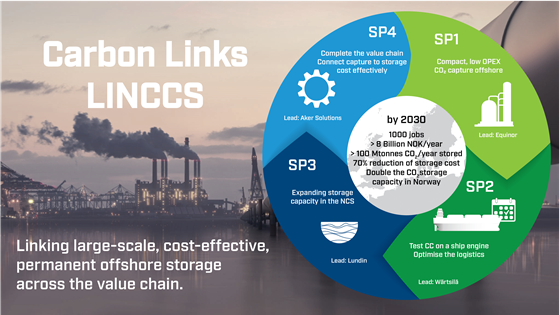

Carbon Links (LINCCS) - Linking large-scale, cost-effective, permanent offshore storage across the value chain.

The PYROCO2 project will demonstrate the scalability and economic viability of carbon capture and utilization (CCU) to make climate-positive acetone out of industrial CO2 and renewable electricity derived hydrogen.

HARARE's overall objective is to eliminate waste from the metallurgical industry while recovering valuable materials and encouraging the use of hydrogen in the industry.

The PERFECOAT project will develop and validate a new generation of industrial wood and decorative coatings with significantly more than 25% bio-based components from climate neutral sources and processes.

In the project, research institutes cooperate with companies to make advanced walls and windows with new or improved properties and a small environmental footprint.

The production of photovoltaic modules generates significant resource flows, much of which currently becomes waste, including silicon kerf, graphite, and silica from ingot production.

The WINNER project aims to develop an efficient and durable technology platform based on electrochemical proton conducting ceramic (PCC) cells designed for unlocking a path towards commercially viable production, extraction, purification and...

In-No-Plastic’s goal is to develop and demonstrate nano-, micro, and macro-plastic clean-up technologies in the aquatic ecosystems.

Hydra will hybridize high-power and high-energy electrode materials to create sustainable Li-ion battery cells with excellent energy density.

REALISE will develop carbon capture, utilization and storage (CCUS) strategies for oil refineries-centered industrial clusters and demonstrate in a pilot scale an absorption technology based on novel solvent for cost-efficient and environmentally...

The main objective of PlastiSea is to develop novel bioplastic materials based on cultivated and wild species of brown algae.

The project aims at better understanding of charge, mass and heat transports in new generation PEM fuel cells MEA for automotive applications.

the objective of the CHANNEL EU project is to develop a low cost and efficient electrolyser stack and balance of plant (BoP) that will become a game-changer for the electrolyser industry.

The main aim of the VIRTUAL-FCS project is to make the design process of hybrid fuel cell and battery systems easier, cheaper and quicker.

DIY4U focuses on digitalizing and transforming European industries and services involved in the formulation, production and supply of particulate and liquid based Fast-Moving Consumer Goods (FMCG), enhancing the innovation capacity and...

The Watereye project will design an advanced monitoring system that will make it possible to remotely detect corrosion levels

COGNITWIN will set a new standard for the design, development and operation of the European process industry by introducing a platform for virtual component-based architecture that integrates IoT, Big data, AI, smart sensors, machine learning and...

Propylene production is classified as the 4th largest emitter of greenhouse gases among the major chemical compounds. As the polypropylene market is huge and still growing, it is essential to find alternatives to current, energy-intensive production...

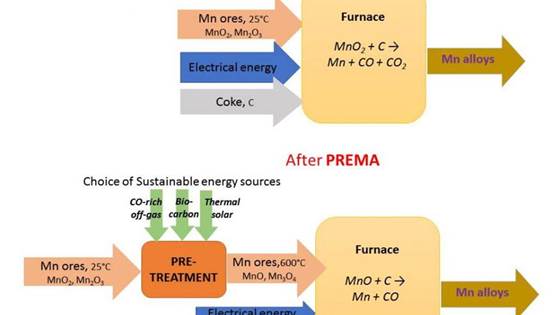

PreMa - Energy efficient, primary production of manganese ferroalloys through the application of novel energy systems in the drying and pre-heating of furnace feed materials, is a H2020 project aimed at demonstrating an innovative suite of...

The main goal of the SecREEts project is to establish a stable and secure supply of critical rare earth elements based on a sustainable extraction from European apatite sources used in fertiliser production.

SUPER PV is pursuing an ambitious bus realistic goal for innovative PV system cost reduction and consequently significant LCOE reduction (26%-37%) by adopting hybrid approach combining technological innovations and Data Management methods along the...

The objective of DACOMAT is to develop more damage tolerant and damage predictable low cost composite materials in particular aimed for used in large load carrying constructions like bridges, buildings, wind-turbine blades and offshore structures...

The GAMER project will develop a novel cost-effective tubular Proton Ceramic Electrolyser (PCE) stack that will produce pure dry pressurized hydrogen. The main objective of GAMER is to design, build and operate a low cost 10 kW electrolyser system...