In order to make a hyperbaric arc model we need to know the thermodynamic properties density, enthalpy and specific heat, and the transport coefficients viscosity, thermal conductivity and electrical conductivity of the arc plasma for typical hyperbaric pressure conditions. We are considering plasmas of either argon or helium or a mixture of the two. In our last ROP project meeting we discussed the availability of these data. To our knowledge data at one atm are readily accessible; both calculated as well as measured. There is an excellent agreement between the calculated and measured data in the temperature range 300-30000 K. However, for hyperbaric pressures the situation is in sharp contrast. Hardly any measurements for pressures above 25 atm exist. And when there are data the temperature range in most cases is too limited to be useful. Measurements at high temperatures and pressures are difficult and unreliable, and calculated values are accepted as more accurate. Thus, the only data available for pressures above 25 atm are calculated from first principles and the Chapman-Enskog method.

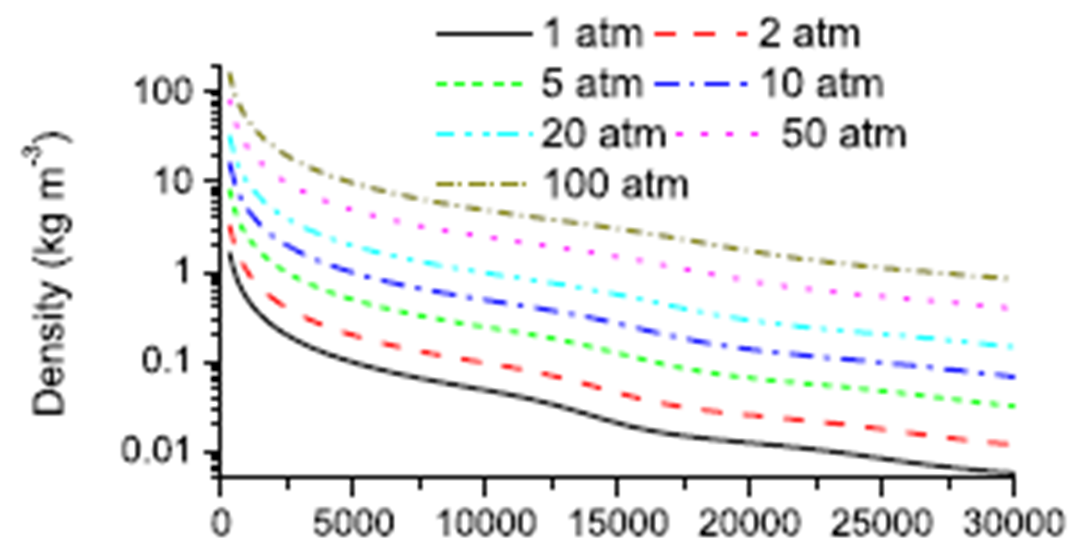

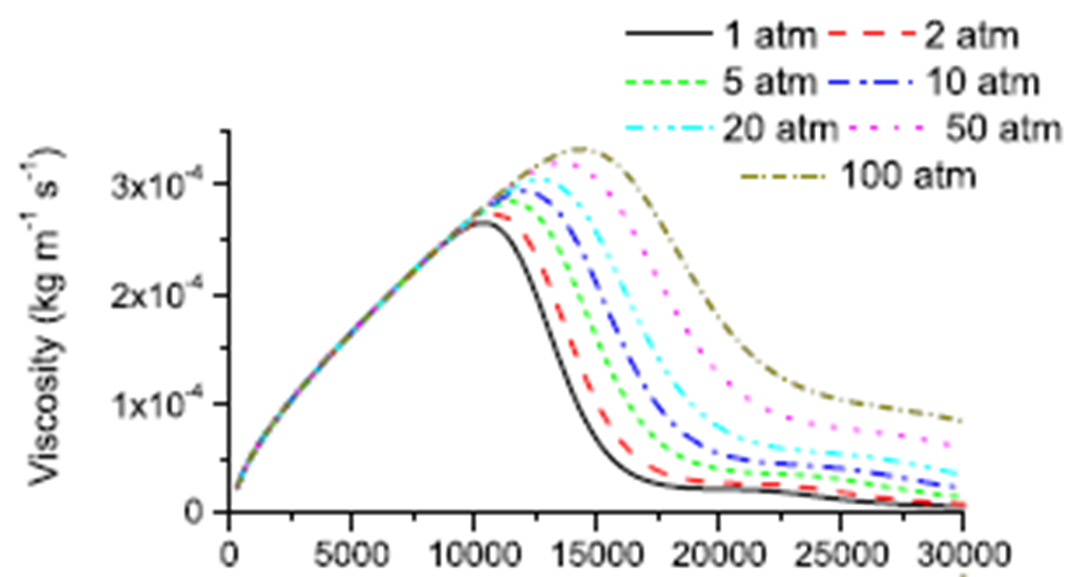

From the comprehensive literature review from last year we observed that A. B. Murphy at CSIRO Australia had published a number of relevant papers, but at atmospheric pressure. We approached Mr. Murphy by email and asked if he could help us with high pressure data. He replied kindly and indeed he could help. In 2014 he published a paper where these data are calculated in the temperature range 300-3000 K and pressure range 1-100 atm for argon, krypton and xenon. The goal for him was to provide simulation data for high intensity discharge lamps (HID-lamps). Typical operating pressures for HID-lamps are 30-100 atm. Murphy has provided us with an Excel file containing this data set. In the figure below we see the density and viscosity of argon taken from this data set.

Furthermore I asked him if it would be any added difficulty in calculating data for pressures as high as 400 atm. He replied that there are no added problems in going up to pressures in the 400 atm range. He was also willing to provide these data on the condition that he will be a co-author of papers using these data. A most generous offer I think. The only thing the ROP project partners have to decide is what shielding gas mixtures are of most interest. I think 3-4 mixtures are realistic to ask for. Your input will be valued!