Research group of Corrosion and Tribology

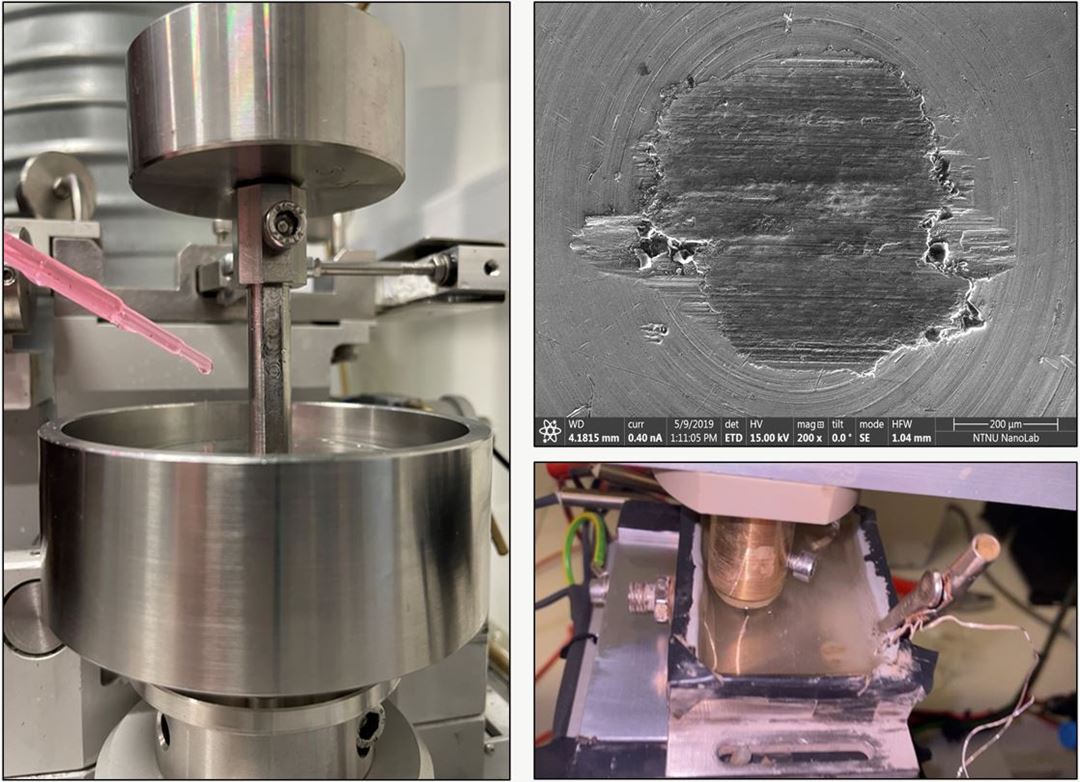

Material degradation due to corrosion and wear often undermines the sustainability of products and processes. We perform research on complex corrosion and wear phenomena and contribute to increased product life, reduced energy consumption and emissions, optimised maintenance and improved safety.

Contact person

Research areas

- Corrosion mechanisms

- Corrosion protection & coatings

- Corrosion monitoring & prediction

- Environmentally assisted cracking

- Friction & Wear mechanisms

- Functional friction & wear coatings

- Wear monitoring & prediction

- Environmentally friendly lubricants

- Functional surfaces, anodising

Research approach

- Collaboration in the SINTEF-NTNU-Industry triangle

- Laboratory based research:

- Electrochemistry laboratory

- Tribology laboratory

- Seawater laboratory

- H2S laboratory

- Wind turbine laboratory

- High-temperature / high-pressure autoclaves up to 200 °C / 200 bar

- Exposure tests, both accelerated and field conditions

- Corrosion- and wear mechanisms as basis for materials development

- Use of numerical simulations and neural network image analysis

Industries that we cooperate with

- Energy production

- Transport and infrastructure

- Mechanical industry

- Process industry, incl. metallurgical

- Lubrication industry, incl. recycling

- Electronics