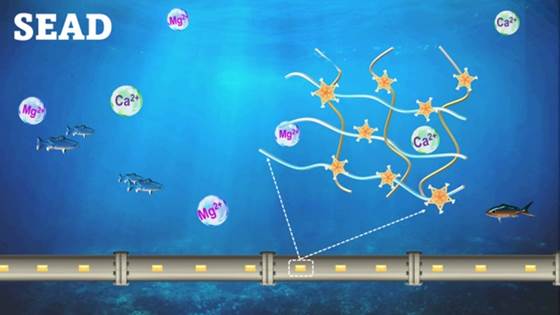

Polymer chemistry lab

In this lab we synthesize polymer materials from monomers. We also modify commercially available materials and make formulations for tailored applications. A third field of R&D is chemical degradation studies to establish routes for chemical...