Foundry and recycling laboratory

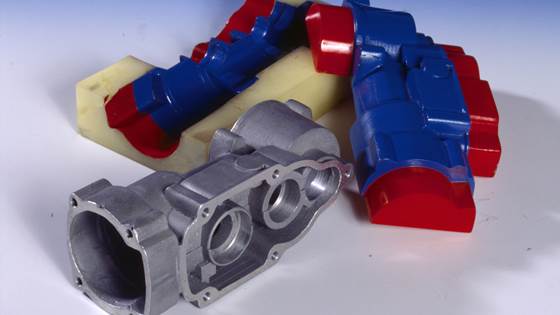

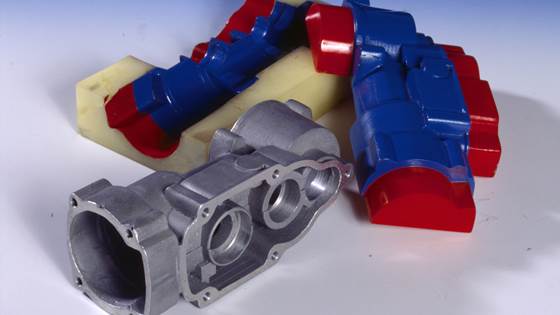

In our foundry and recycling laboratory we work with casting, recycling and melt treatment of metals such as aluminium, iron, steel, titanium, magnesium and copper-based alloys.

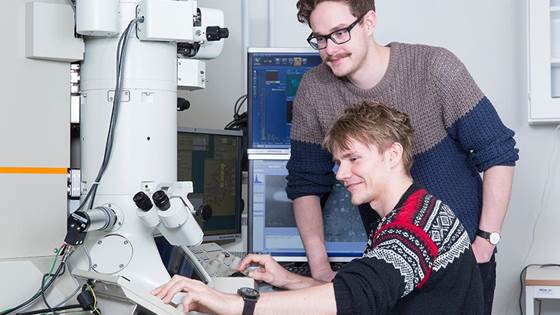

Our skilled staff analyses results and data from our high-quality laboratories, where we design and carry out controlled, reliable and repeatable experiments. We co-operate with other SINTEF units to offer sustainable and multi-angelled solutions to our client's challenges.

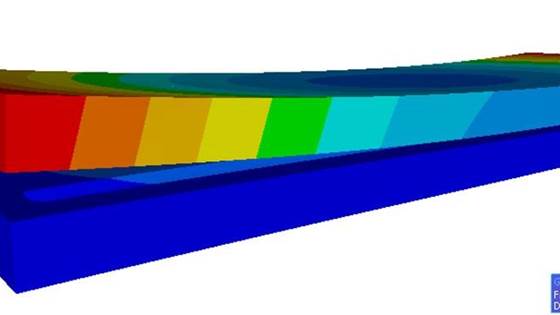

Our well-equipped and up to date infrastructure and the unique competence of the staff is the backbone of the research groups scientific quality. The research group has been working with refining, casting, forming, and recycling for several decades. Very often in close cooperation with industrial customers either through projects funded by the Norwegian Research Counsil (NRC) or directly funded by the customers. We cooperate with international customers through EU projects, NRC projects or in direct projects. Within casting the group has very good reputation nationally and has contributed significantly to increase productivity and quality and reduce scrap-casting at many national foundries. Within forming our material and process knowledge has been used in development of new aluminiumalloys and optimalization of customer products and processes. Within recycling and refining we are at the international research front especially for aluminium alloys. Additive manufacturing is a growing competence field for the research group. The group already contributes to several national and international projects within this emerging and exciting field.

In our foundry and recycling laboratory we work with casting, recycling and melt treatment of metals such as aluminium, iron, steel, titanium, magnesium and copper-based alloys.

Additive manufacturing is a growing competence field for the research group. The group already contributes to several national and international projects within this emerging and exciting field.

In our unique wetting laboratory, we have competence on investigating interactions between liquid and solid materials at high temperatures. It is vital for the progress of metallurgical processes to further improve the understanding of reactions...

AluMar will develop improved, seawater-resistant aluminium components for marine applications.

Aluminium is extensively used in food packaging because it provides a unique durability. Longer durability leads to less food wastage. The challenge is to make sure that the aluminium packaging is reclaimed and goes back into the circuit. The main...

Automotive car makers increasingly use light-weight aluminium structures to reduce the environmental footprint of cars during life-of-use (lower energy consumption) and to allow for the heavy batteries used in electric vehicles.

An interdisciplinary Centre for Research-based Innovation (SFI). Focus: During the next decades, the Norwegian metal industry will need to achieve even higher-quality output with more efficient use of materials and energy.

PhysMet is an interdisciplinary center for research-based innovation (SFI) in physical metallurgy. Our goal is to establish knowledge and technology to realize new innovative material solutions in cost-effective, low-carbon production chains in the...

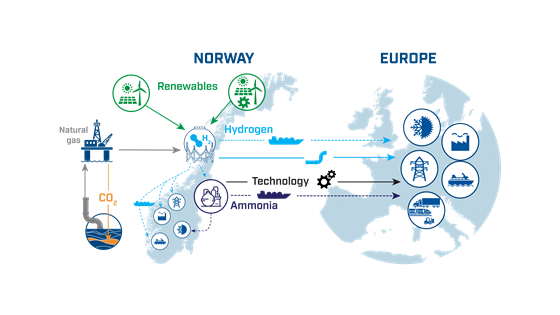

HYDROGENi is a centre for environment-friendly energy research (FME) dedicated to the research and innovations within hydrogen and ammonia needed to meet the 2030 and 2050 goals of the Norwegian hydrogen road map.