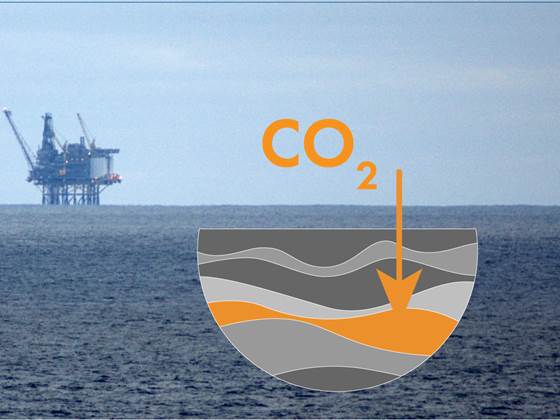

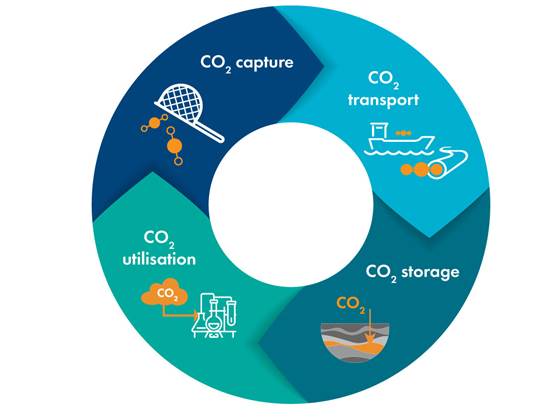

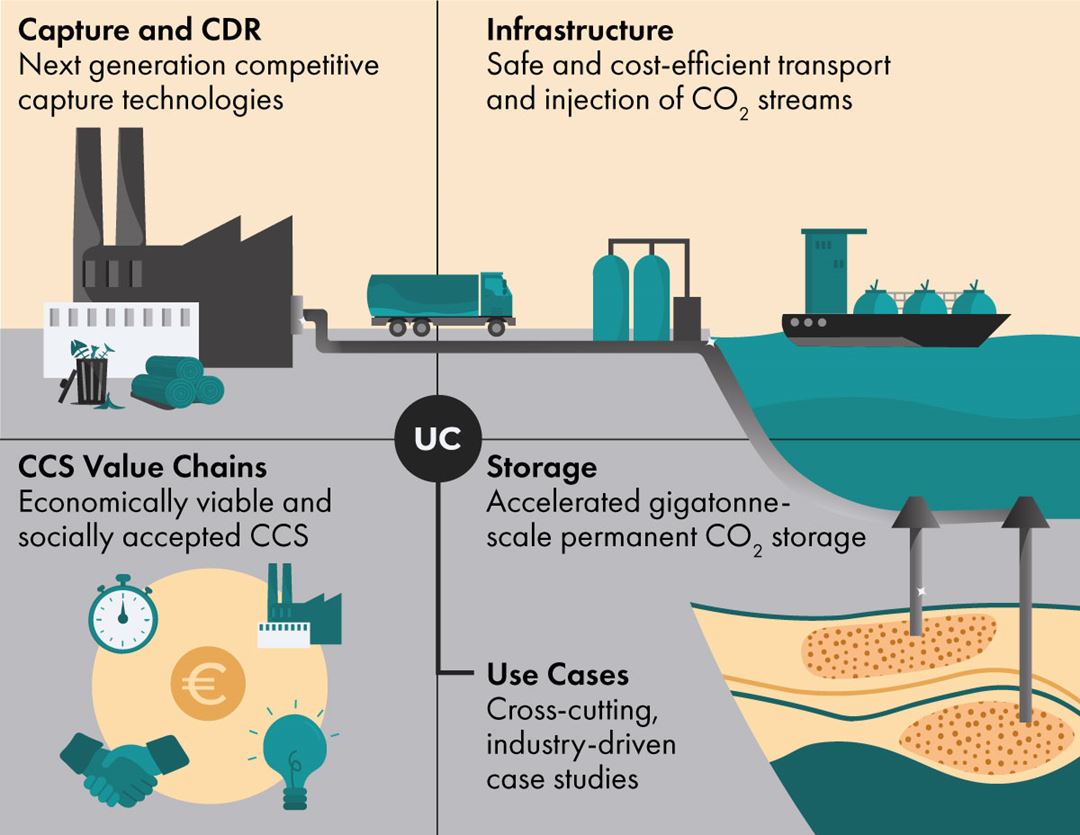

CCS involves capturing waste CO2 from industrial processes, transporting it in concentrated form and injecting it deep underground.

Why CCS Matters

The IPCC found that to meet the challenging targets of the Paris Agreement, global CO2 emissions must be reduced by 50-85 % by 2050. IEA findings say that to meet these targets, 14% of the total emissions reduction by 2060 must come from CCS.

Also, CCS is today also the only way to decarbonise some of the world's critical industrial sectors, including cement, metal production and waste incineration. This matters, because the global cement industry, for example, accounts for around 8% of CO2 emissions.

The storage capacity within the geological layers on the Norwegian continental shelf gives Norway great opportunities to create value and new green employment by realizing CCS.

Decades of CCS Research Experience

The recent announcement of the Longship project by the Norwegian government has brought the concept of CCS into the mainstream. Together with our partners at NTNU, SINTEF researchers have been working on CCS for decades.

Today, SINTEF conducts research on the whole value chain for CO2 capture, transport and storage.

CCS Research Expertise

SINTEF hosts the Norwegian CCS Research Centre (NCCS), a continuation of the successful BIGCCS research centre. NCCS aims to research solutions to key technical and cost challenges in order for us to fast-track the deployment of CCS at scale.

Our researchers work closely with both academics and industrial partners to ensure that quality scientific results can be successfully applied to industrial problems.

CCS Research Labs

SINTEF invests heavily in research infrastructure. From CO2 storage research at our Reservoir Lab to the world-class Multiphase Flow Lab, SINTEF offers many specialist research facilities relevant for CCS research.

SINTEF is a proud member of the ECCSEL network of European CCS research infrastructure. 11 relevant labs in Oslo and Trondheim are available as part of the pan-European distributed research infrastructure.

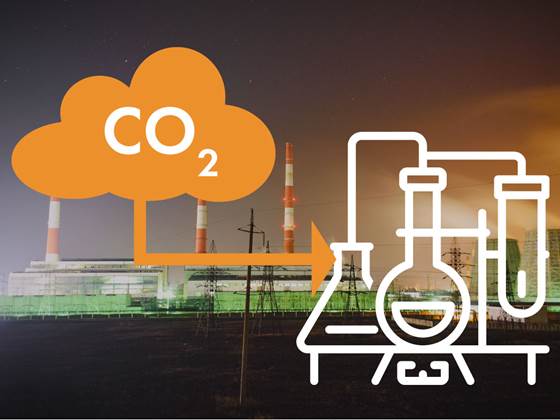

Utilization of captured CO2 (CCU)

CO2 captured from emission sources (CCU) can be converted into valuable chemicals and materials. Alongside carbon capture and storage (CCS), the utilization of captured CO2 will have a positive climate impact. Reusing carbon will not only reduce overall CO2 emissions, but also offer economic benefits to industries by transforming it into valuable products rather than incurring storage costs.

At SINTEF, we research and improve CCU technologies and processes to reduce energy consumption, develop efficient and scalable processes, and create new products from CO2. Our goal is to maximize product yield, utilize waste and by-products, and promote sustainable carbon management.