What is circular manufacturing?

Circular manufacturing creates systems where resources, materials, and products are reused, remanufactured and recycled.

One of the primary goals of circular manufacturing is to minimize waste and pollution.

Key aspects of circular manufacturing:

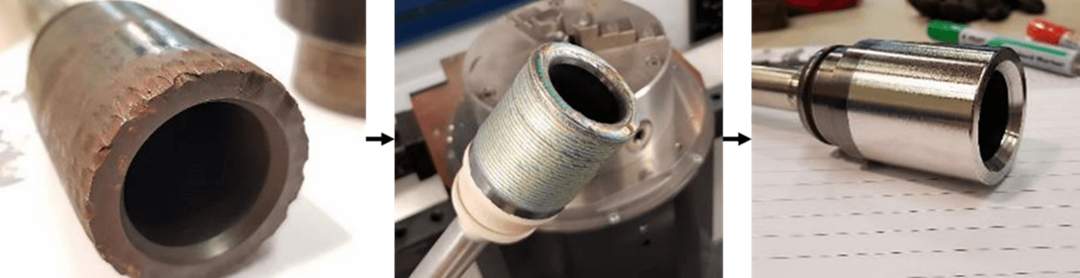

- Designing products and manufacturing processes for durability, reuse, refurbishment, and recycling.

- Using recycled and renewable materials as inputs.

- Using modular design to facilitate maintenance, repair, and remanufacturing.

- Recovering and reusing materials and energy on-site

- Leveraging digital technologies like IoT sensors, blockchain, and so on.

- Adopting new business models like product-as-a-service.

- Building industrial networks where the waste from one industry/process is used as a resource for another.

Circular strategies, companies and research

Circular strategies may include closing loops, slowing loops, intensifying loops, narrowing loops, and dematerialising loops, and typically include multiple actors in the value chain and industry sectors.

Manufacturing companies play a key role in achieving the goal of green and digital twin transition through enhancing circularity, facilitating decarbonisation whilst enhancing competitiveness.

Research topics address challenges of the circular manufacturing transition and development of innovative solutions and tools for achieving circular manufacturing systems with minimal environmental footprint. New circular products and related services are essential, paving the way for new business models.

Also, this transition requires new mindsets and expertises, with emphasis on human aspects of development and uptake of technologies, and upskilling/reskilling of the workforce. A broad range of digital technologies have a great potential to accelerate the circularity.

Data pooling

Data pooling and sharing among sectors and across the whole value chain, as well as the use of external environmental impact data such as LCA-data, would facilitate recycling and remanufacturing, by modelling and monitoring the life cycle of products and components.

Such data pooling would enable a better insight into the environmental footprint, including the CO2-footprint, of products and components. To achieve that, there is a need to build trust by ensuring data exchange and interoperability across industry sectors and relevant stakeholders, while also focusing on aspects like data quality, cybersecurity, reliability, and accessibility.

Preparing for the future

The forthcoming Sustainable Product Framework (SPI) that has been announced as part of the Circular Economy Action Plan 2.0 in 2020 is proposing the Digital Product Passport to electronically register, process and share product-related information amongst supply chain businesses, authorities and consumers, therefore the manufacturers should be prepared for its implementation.