Designing measurement technology in a multidisciplinary team

Most of the sensors we have developed for the food industry have been optical, where we have developed measurement solutions based on imaging and spectroscopy. Spectroscopy is a way of measuring the composition of food by measuring a light interaction fingerprint. For example, the light will have a different signature depending on whether the food has a high or low-fat percentage, or similarly if it has high or low protein content. We have been very lucky to work closely with food spectroscopists at Nofima, who have given us greater insight into how light interacts with food and what the end-user needs when measuring food quality parameters, for example, how accurate does it need to be, what speed does it need to operate at or the specific requirements of the industrial environment it needs to operate in. The iterative process that occurs when you discuss challenges from different perspectives often leads to creative ideas.

Following the light for better design

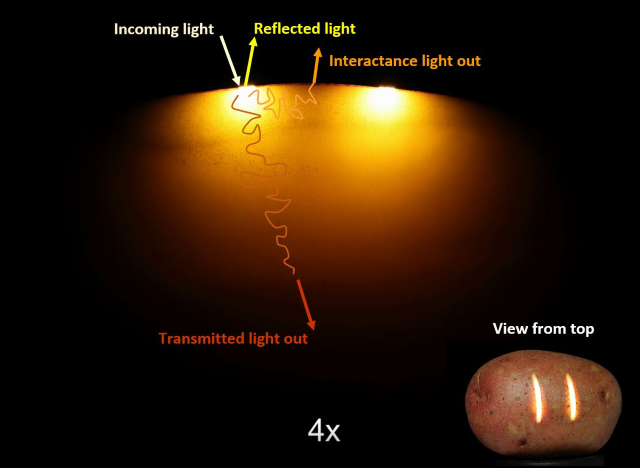

One of our commercial success stories, QVision, started with a design challenge that was solved by better understanding the interaction between food and light. Measuring light that has been transmitted through the food gives more stable representative measurement than if it were just reflected off the surface. This is because the light interacts with more of the food, allowing better 'coverage' of food, which is especially important if the food is heterogeneous. However, to get through the food (transmitted light), you must access the food from both sides, which is not very practical in most industrial cases, for example on a conveyor belt. Another difficulty is that light intensity is significantly reduced when it travels longer paths, and this means you cannot measure as fast because you need to pause to collect enough light.

This led to us developing a hybrid geometry that benefits from the best of both worlds. Instead of measuring the light on the other side of the product, we took advantage of the fact the light bounces all around the inside of the food. We designed a high-speed system that measures light after it has bounced around and exited just a short distance away, on the same side as it entered the food (interactance light). It will not have travelled as far as the transmitted light, but it will have covered more of the food than light that has just bounced off the surface. The best of both worlds! With careful design, we have achieved very high measurement speeds, making it suitable for measuring food on conveyor belts travelling at up to 2m per second.

The random path of a photon is illustrated as it bounces around the inside of the food.

Where are we now, and where are we going?

When research over many years, applying sensor technology in a specific industry, you build a specific kind of expertise that should be further built upon for generating further innovation. This is why, Nofima, SINTEF and NMBU have established a Centre for Research and Innovation called Digifoods, enabling a long-term strategy for digitalisation in the food industry, focussing on a combination of novel optical sensors, robotics, and advanced data analytics. The centre has many partners covering different stages of the food and technology value chains. Our consortium is paving the way for an exciting research and innovation journey for the food industry.