Transport of CO2 in pipelines is a key technology to enable large scale CO2 capture and storage (CCS). CO2 Dynamics contains several flow model formulations and thermodynamic equation of states in order to be able to simulate CO2 pipe flow under various conditions and fluid compositions. In particular, the robust numerical methods handle fast transients, discontinuities and wide or narrow phase envelopes. This tool may be used to study depressurization and distribution of state variables like temperature. CO2 Dynamics has an interface to Thermopack for access to thermodynamic property models. Examples of engineering applications are pipeline design, estimation of how much CO2 is flowing, the lowest occurring temperatures and running fractures.

Validation

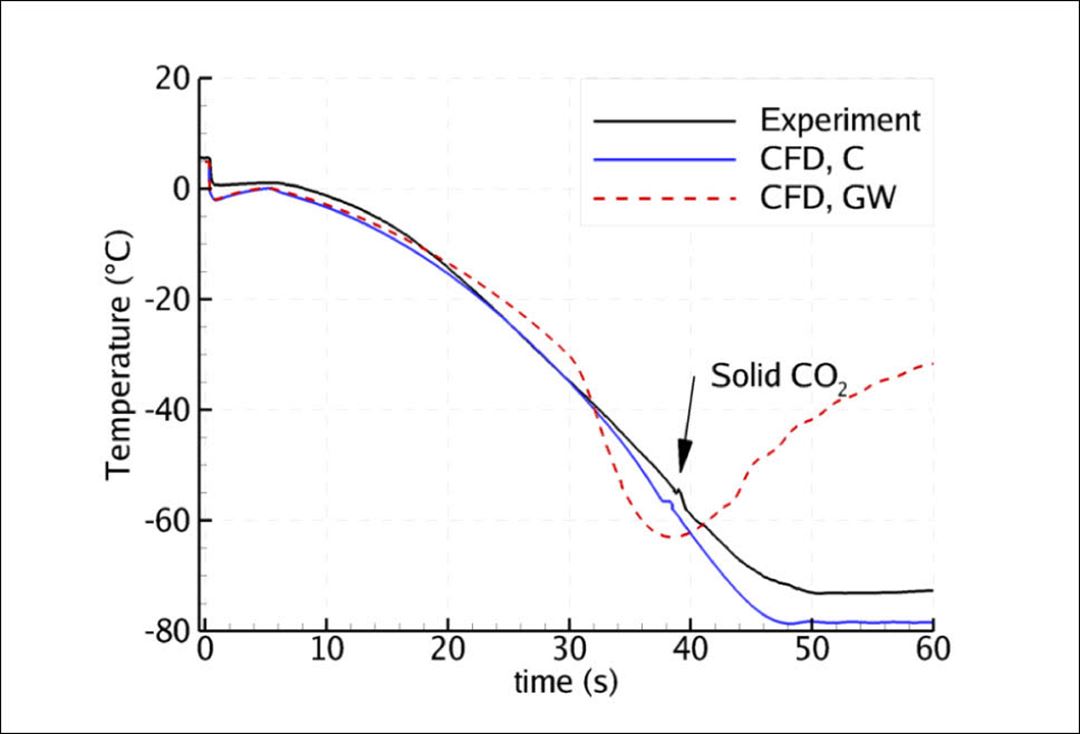

CO2 Dynamics has been validated against various experimental data. An example is depicted in the figure below for the depressurization of a 200 m pipe, where one end of the pipe was opened to the atmosphere while the other remained closed. As a consequence, temperature and pressure starts falling in the pipe.

The temperature calculated with CO2 Dynamics was compared to experimental data from DNV GL. at a point 5 meter from the closed end of the pipe. Two different heat-transfer models were used ('C' denotes Colburn and 'GW' denotes Gungor-Winterton). In this case, the Colburn heat-transfer correlation gives better results. The reason for the large difference is the occurrence of solid CO2 (dry ice). This can be seen as a kink in the experimental data (and in our calculation) at time about 40 s. The Gungor–Winterton correlation gives too high heat transfer, such that the CO2 does not enter into the area where solid CO2 is formed. As can be seen, the solid CO2 contributes to keeping the temperature low.

This calculation shows that CO2 flow and depressurization models must be able to account for the formation of solid CO2. Secondly, it is important to model the heat transfer through the pipe wall to the surroundings.

Further reading:

- CO2 transport

- #SINTEFblog: Flow of CO2 in pipes