P-FAT, SN analysis and Crack growth analysis

P-FAT imports the stress field from a linear, static FE analysis of a structural component. The analysis is done assuming an undamaged component (fatigue cracks need not be modelled). The stress field has been computed by applying a "unit load" to the component. In P-FAT, unit loads are multiplied by load histories, typically obtained in a dynamic analysis of the structure as a whole. This results in a complete description of how the stresses evolve over time at each point within the component, and provides the base for the fatigue analysis.

SN analysis

P-FAT can compute the fatigue life using the widely accepted engineering procedure of using a Wöhler (SN) curve, typically a conservative "design curve" from engineering standards, combined with rainflow counting and Palmgren-Miner summation.

The traditional engineering criteria provide binary answers (acceptable/unacceptable). P-FAT allows to go beyond that and evaluate the probability of failure of a given component based on weakest-link theory, provided that a) the uncertainty on the load side is negligible and b) the scatter of SN data is available. The probability of failure computed by P-FAT takes into account the "volume effect": for a given stress amplitude, if a larger volume of material is loaded, the probability of failure increases.

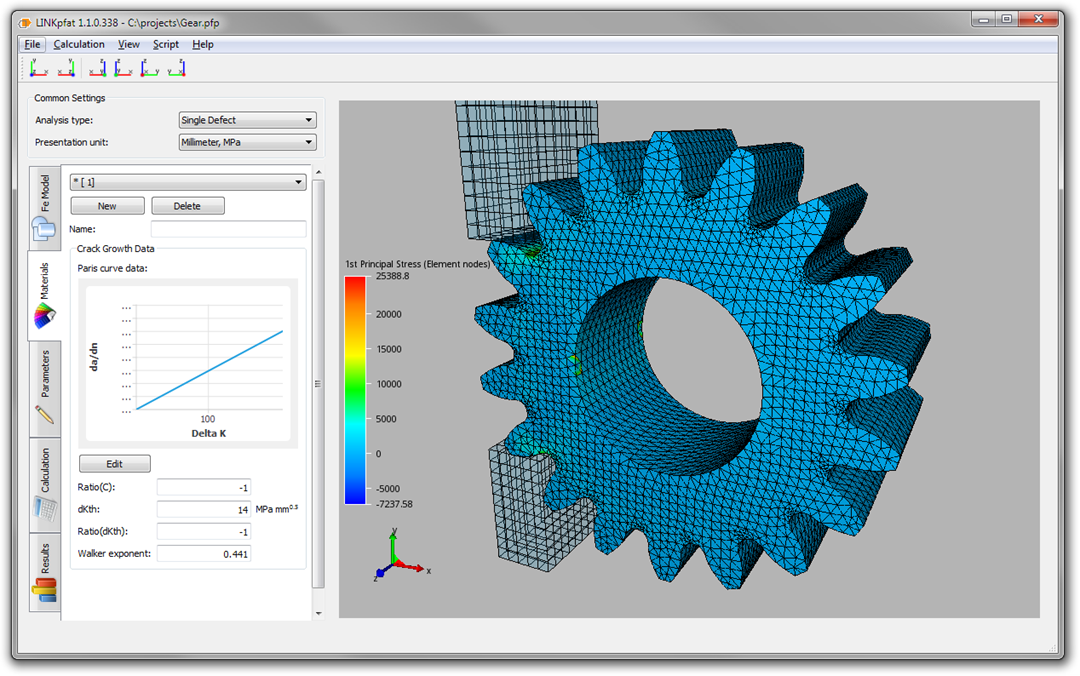

Crack growth analysis

If a fatigue crack pre-exists in the component, crack growth is traditionally computed using Paris law (or refinements of it). If the un-cracked component has strong stress gradients, then computing crack growth using the highest stress (computed using a stress concentration factor) can be very conservative. Design codes permit a more precise analysis which accounts for the stress, but this is seldom used in practice because the computations are more complex. P-FAT makes this option easily available.