Project overview

A battery separator is an ion-permeable membrane installed between the anode and cathode of the battery to separate the electrodes to prevent short circuits. For Li-S batteries, it is vital that Li+-ions can pass, but intermediate reaction products where lithium is chemically bound to sulfur (so-called lithium polysulfides, Li2Sx) are blocked at the cathode side.

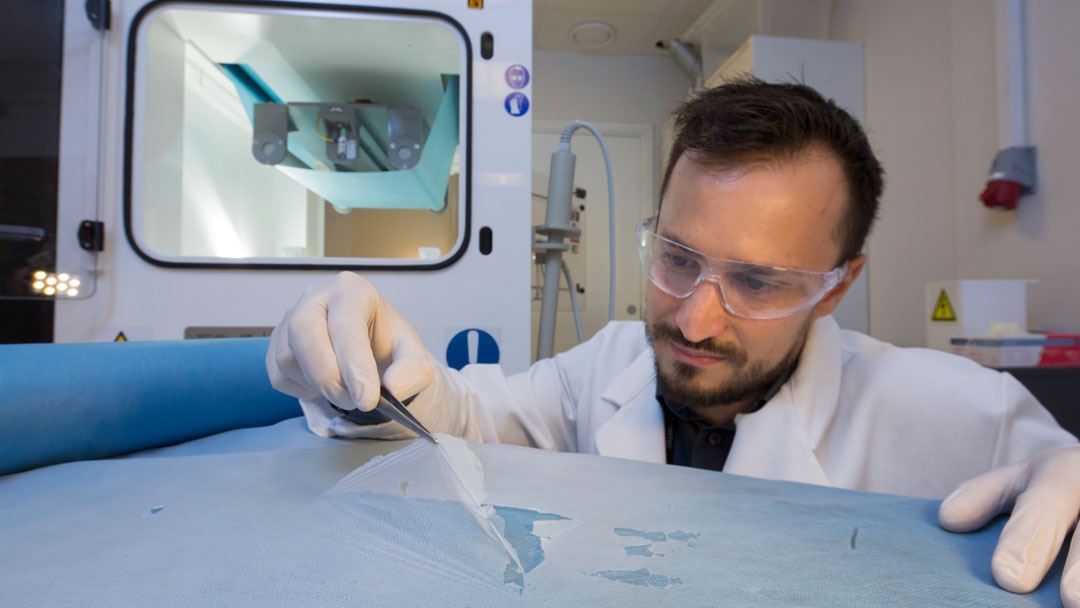

The goal of the 3S Battery project is to develop highly effective membranes as separators with tailored functionalities using advanced nanostructures and/or coatings to mitigate the issues caused by polysulfide migration and dendrite formation. The defined separator should act as a selective medium that effectively suppresses the polysulfides migration while facilitating the Li+ ion transport with uniform distribution. Functional coatings will also reactivate the trapped sulfur to increase cathode efficiency.

The developed separators are expected to enable Li-S batteries to achieve high performance as indicated by the project’s key performance indicators (KPI), including high cycle stability of >2000 cycles, corresponding to a capacity decay of ~0.01% per cycle, with an initial discharge capacity of ~1300 mAh g-1 at a 0.1 C.