Oxides for batteries

Oxides for batteries

The use of batteries has increased dramatically in the recent years, due to the market entrance of Li-ion batteries. There is enormous interest in battery technology for the transition to green energy in e.g. transport (road, rail, maritime), grid storage (peak shaving, frequency regulation, backup), and for remote energy storage.

For further implementation of rechargeable batteries in transportation, energy density must be increased and two routes are mainly explored: increased capacity and increased voltage, which both call for new materials.

Oxide materials are currently used as cathode materials in Li-ion batteries. A variety of techniques is used by SINTEF for tailoring the composition and structure of the cathodes in order to increase the capacity and the operational voltage.

Objectives in OXIPATH

In Oxipath, SINTEF will develop modified high energy cathodes with special focus on maritime applications, within the NMC material family. Electrochemical testing protocols have been established, and the on-going characterization shows that the properties are comparable to state-of-the-art cathodes. We are also preparing environmentally friendly slurries with high loadings of active material for tape casting and screen printing of electrodes for future commercial production. Oxipath will also generate hands-on competence on the assembly and testing of a full battery to define best practices and evaluate the effects of cell and components geometry and property on overall performance.

Solid-state batteries

All-solid-state batteries are investigated for future battery systems, due to their proposed high energy density attainable by direct-series-stacking of cells and their enhanced safety. SINTEF is investigating novel materials solutions as potential solid state electrolyte candidates.

What SINTEF can offer

For more information about SINTEF's competence on batteries:

For more information about other projects related to piezoelectric materials:

- MOZEES is a Norwegian Centre for Environment-friendly Energy Research (FME) where SINTEF has a large activity related to battery development.

- ADMIRE, where SINTEF is developing amorphous vanadium oxide cathodes for magnesium oxide batteries.

- ZAS, European H2020 project about zinc-air batteries coordinated by SINTEF

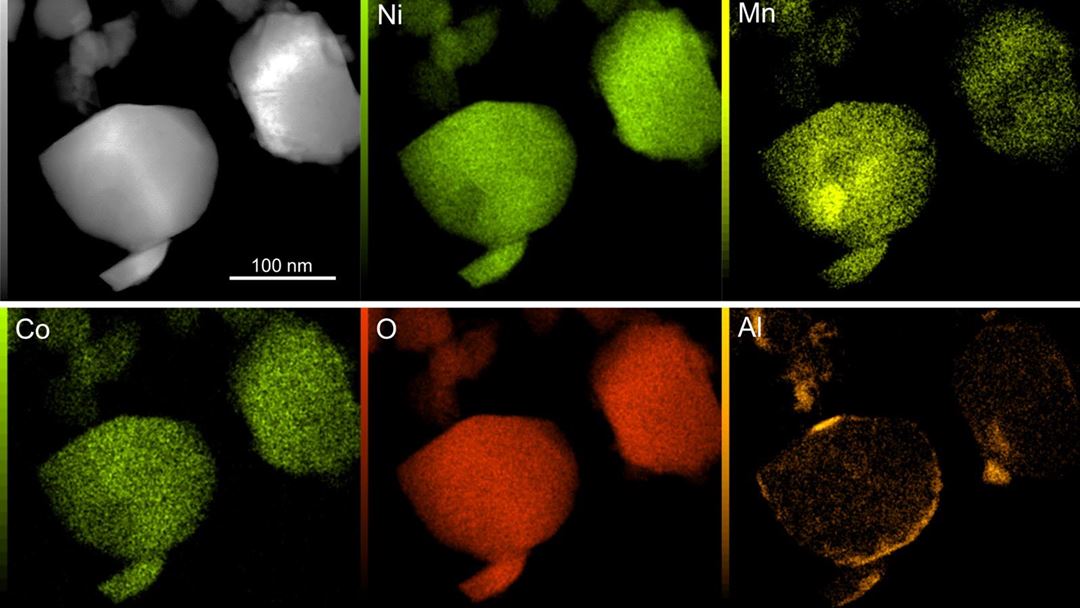

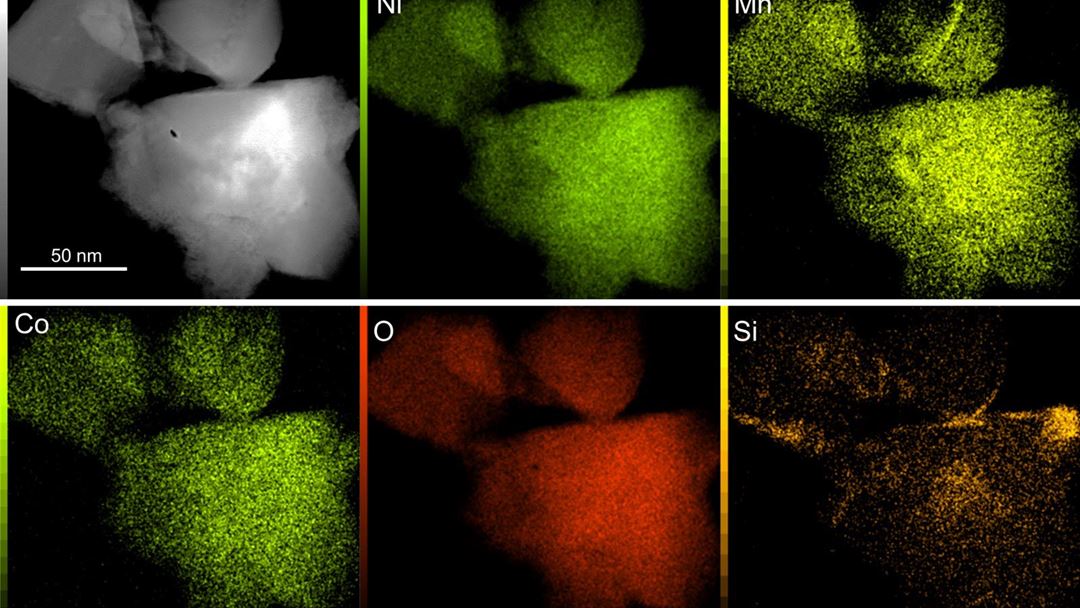

Mapping of elements in a lithium ion battery cathode material, where the particles have been coated by protective aluminium oxide (above) and silicon oxide (below). The mapping was made by STEM-EDS analysis