The laboratory supports different testing labs through:

- Positioning of test samples (e.g., sub-sized fracture mechanics samples from HAZ, fusion line or weld metal)

- Positioning of notches and fatigue pre-cracks (corrosion and mechanical/fracture mechanical testing)

- General documentation of weldments

- Macrophoto

- Macro hardness measurements as mentioned above (to obtain information on maximum hardness and hardness distribution information)

- Weld defects (cracks, porosity, lack of fusion/penetration, inclusions/slag, undercuts, etc.) and built up of individual beads/layers

- Brittle fracture initiation

- Initiation of corrosion attacks

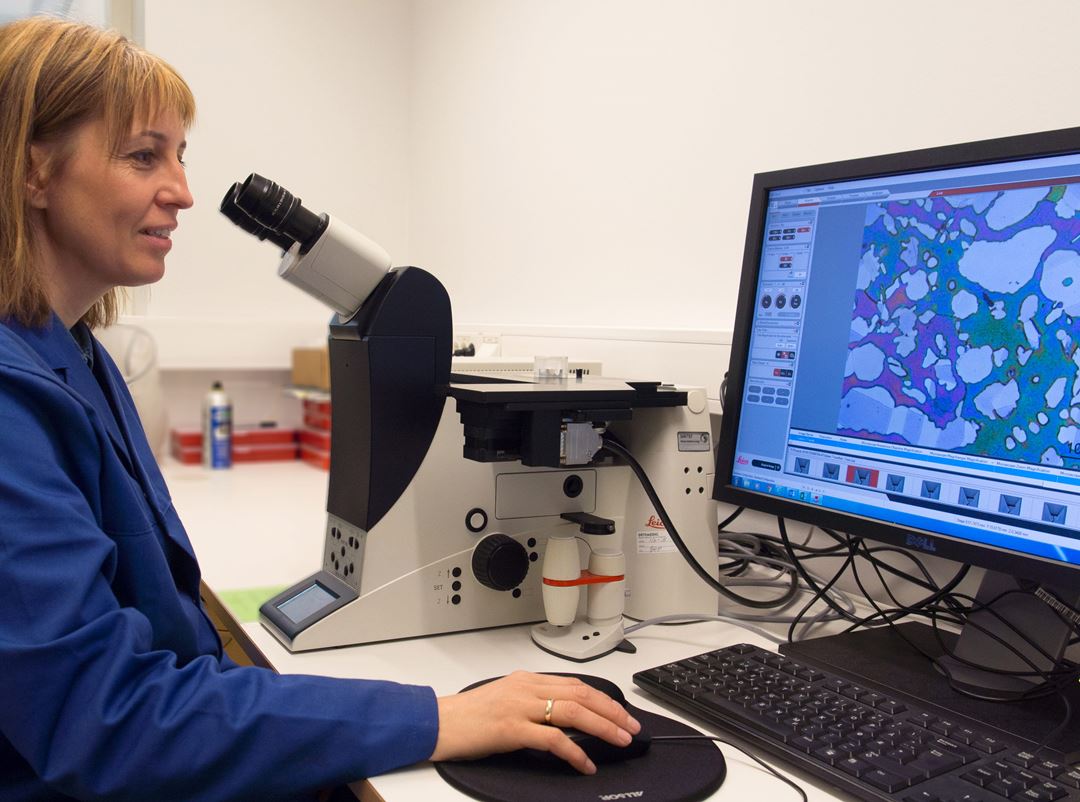

In addition, the laboratory is equipped with microscopes used for

- Quantitative microstructure analyses

- Solidification microstructure (dendritic, cellular, etc.)

- Volume fractions of phases (examples are martensite-austenite, M-A, constituents in welding of structural steel, formation of sigma phase in duplex stainless steel, etc.)

- Ferrite content and austenite spacing in duplex stainless steel

- Grain size

- Microhardness measurements to achieve information on local properties of inhomogeneous materials

- Damage and failure analyses

- Characterization of stress corrosion cracking (SCC) and sulphides stress cracking (SSC)

The following equipment is available:

- Cutting machines

- Hot mounting press and cold mounting systems

- Grinding and polishing equipment

- Equipment for electrolytic polishing and etching

- Stereo microscope

- Light optical microscope with fully motorized stand

- Micro hardness tester with test force of 5 kgf to 500 gf

- Hardness tester with test force of 200 gf to 30 kgf. The test cycle is fully motorised.