SINTEF has expertise and practical experience with many of the commercial "additive materials", for various additive manufacturing (AM) processes for metals and plastics/composites.

SINTEF is also updated on the development of such materials. The feedstock for AM machines ("3D printers") is one or more materials in the form of powder, filament/wire, liquid, paste etc. SINTEF has equipment for characterizing these feedstocks in terms of chemical and physical properties.

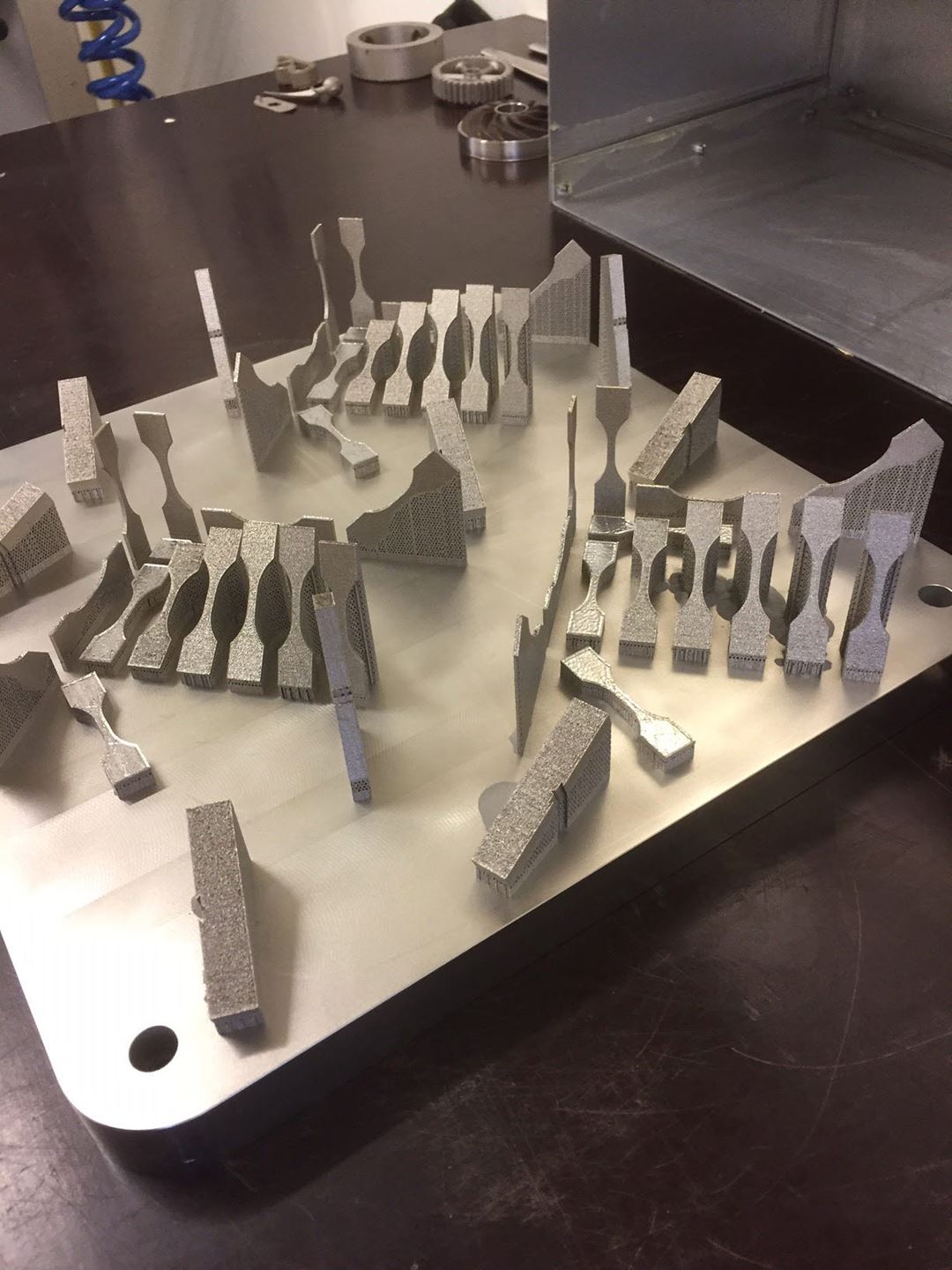

With regard to industrial AM, the material properties of the final part are important, and in several projects SINTEF has mapped and analyzed mechanical properties and repeatability. Process-induced microstructures and possible defects are part of this picture. The material properties are influenced by the AM process (and process parameters), and in some cases the mechanical properties have significant anisotropy.

SINTEF also performs advanced mechanical testing in order to develop, calibrate and verify material models for numerical simulations (structural analysis, topology optimization).

SINTEF is also working on establishing process parameters for AM with "new" materials (typically metals and plastics used in other processes, but not so far not in AM). Such materials can e.g. be special steel alloys and nickel alloys.

SINTEF also develops materials for functional applications. One example is ceramic materials for piezoelectric components. Another example is bioprinting materials where the goal is to create tissues and organs, initially only for research purposes.

Some of SINTEF's experts in materials for AM:

- Metals: Vegard Brøtan, Klas Magnus Boivie, Olav Åsebø Berg, Mohammed Mhamdi, Amin Shahrestani Azar, Magnus Eriksson, Xiaobo Ren, Rune Østhus, Kristian Leonard Aas (pulverteknologi), Carlos Adolfo Grande

- Plastics (polymer materials), rubbers and composites: Erik Andreassen, Benjamin Alcock

- Ceramic materials: Marie-Laure Fontaine, Carlos Adolfo Grande

- Materials for bioprinting: Hanne Haslene-Hox, Øystein Arlov

- Materials for architecture/buildings: Nathalie Labonnote