compositional: Equation-of-state compositional solvers¶

#.. include:: mrst/compositional/README.txt

Models¶

Base classes¶

-

Contents¶ MODELS

- Files

- GenericNaturalVariablesModel - GenericOverallCompositionModel - ThreePhaseCompositionalModel - Base class for compositional models

-

class

ThreePhaseCompositionalModel(G, rock, fluid, compFluid, varargin)¶ Bases:

ReservoirModelBase class for compositional models

Synopsis:

model = ThreePhaseCompositionalModel(G, rock, fluid, compFluid)

Description:

This is the base class for several compositional models in MRST. It contains common functionality and is not intended for direct use.

Parameters: - G – Grid structure

- rock – Rock structure for the reservoir

- fluid – The flow fluid, containing relative permeabilities, surface densities and flow properties for the aqueous/water phase (if present)

- compFluid – CompositionalFluid instance describing the species present.

Returns: model – Initialized class instance

See also

NaturalVariablesCompositionalModel,OverallCompositionCompositionalModel-

computeFlash(model, state, dt, iteration)¶ Flash a state with the model’s EOS.

-

getScalingFactorsCPR(model, problem, names, solver)¶ #ok Get scaling factors for CPR reduction in

CPRSolverADParameters: - model – Class instance

- problem –

LinearizedProblemADwhich is intended for CPR preconditioning. - names – The names of the equations for which the factors are to be obtained.

- solver – The

LinearSolverADclass requesting the scaling factors.

Returns: scaling – Cell array with either a scalar scaling factor for each equation, or a vectogetComponentScalingr of equal length to that equation.

- SEE ALSO

CPRSolverAD

-

storeDensities(model, state, rhoW, rhoO, rhoG)¶ Densities

-

EOSModel= None¶ EquationOfState model used for PVT and phase behavior

-

EOSNonLinearSolver= None¶ NonLinearSolver used to solve EOS problems that appear

-

dzMaxAbs= None¶ Maximum allowable change in any mole fraction

-

fugacityTolerance= None¶ Tolerance for fugacity equality (in units 1/barsa)

-

incTolComposition= None¶ Increment tolerance for composition

-

incTolPressure= None¶ Relative increment tolerance for pressure

-

useIncTolComposition= None¶ If true, use increment tolerance for composition. Otherwise, use mass-balance.

Different formulations¶

-

Contents¶ NATVARS

- Files

- equationsNaturalVariables - Equations for natural variables formulation NaturalVariablesCompositionalModel - Natural variables model for compositional problems ReducedLinearizedSystem - Linearized system which performs a Schur complement before solving

-

class

NaturalVariablesCompositionalModel(G, rock, fluid, compFluid, varargin)¶ Bases:

ThreePhaseCompositionalModelNatural variables model for compositional problems

Synopsis:

model = NaturalVariablesCompositionalModel(G, rock, fluid, compFluid)

Description:

The natural variables model relies on separate primary variables for saturations in the multiphase region. This makes it possible to perform certain heuristics to ensure convergence (e.g. saturation chopping) since there is a weaker correspondence between saturations and the compositions. However, this formulation traverses the phase boundary as a number of discrete steps and can take more nonlinear iterations for some problems.

Parameters: - G – Grid structure

- rock – Rock structure for the reservoir

- fluid – The flow fluid, containing relative permeabilities, surface densities and flow properties for the aqueous/water phase (if present)

- compFluid – CompositionalFluid instance describing the species present.

Returns: model – Initialized class instance

See also

ThreePhaseCompositionalModel,OverallCompositionCompositionalModel-

allowLargeSaturations= u'false'¶ Allow sum of saturations larger than unity (experimental option)

-

maxPhaseChangesNonLinear= u'inf'¶ Maximum number of phase transitions for a given cell, during a nonlinear step (experimental option)

-

reduceLinearSystem= u'true'¶ Return ReducedLinearizedSystem instead of LinearizedSystemAD

-

class

ReducedLinearizedSystem(varargin)¶ Bases:

LinearizedProblemLinearized system which performs a Schur complement before solving the linear system

-

B= None¶ Kept upper block

-

C= None¶ Eliminated upper block

-

D= None¶ First lower block

-

E= None¶ Second lower block

-

E_L= None¶ Lower part of LU-factorized E-matrix

-

E_U= None¶ Upper part of LU-factorized E-matrix

-

f= None¶ First part of right-hand-side

-

h= None¶ Last part of right-hand-side

-

keepNum= None¶ Number of equations to keep after elimination

-

reorder= None¶ Reordering indices for the variables before elimination

-

-

equationsNaturalVariables(state0, state, model, dt, drivingForces, varargin)¶ Equations for natural variables formulation

-

Contents¶ OVERALL

- Files

- OverallCompositionCompositionalModel - Overall composition model for compositional problems

-

class

OverallCompositionCompositionalModel(varargin)¶ Bases:

ThreePhaseCompositionalModelOverall composition model for compositional problems

Synopsis:

model = OverallCompositionCompositionalModel(G, rock, fluid, compFluid)

Description:

The overall composition model relies on primary variables pressure and overall compositions for all components. As a consequence, the the phase behavior and mixing is offloaded to the equation of state directly. A requirement for this model is that the equation of state is fullfilled at each Newton iteration.

Parameters: - G – Grid structure

- rock – Rock structure for the reservoir

- fluid – The flow fluid, containing relative permeabilities, surface densities and flow properties for the aqueous/water phase (if present)

- compFluid – CompositionalFluid instance describing the species present.

Returns: model – Initialized class instance

See also

ThreePhaseCompositionalModel,NaturalVariablesCompositionalModel

PVT models¶

Equations of state¶

-

Contents¶ EOS

- Files

- EquationOfStateModel - Equation of state model. Implements generalized two-parameter cubic EquilibriumConstantModel - Equilibrium constant EOS model for problems where functions of the

-

class

EquationOfStateModel(G, fluid, eosname)¶ Bases:

PhysicalModelEquation of state model. Implements generalized two-parameter cubic equation of state with Newton and successive substitution solvers, as well as standard functions for computing density and viscosity.

-

computeFugacity(model, p, x, Z, A, B, Si, Bi)¶ Compute fugacity based on EOS coefficients

-

computeLiquidZ(model, A, B)¶ Pick smallest Z factors for liquid phase (least energy)

-

computeVaporZ(model, A, B)¶ Pick largest Z factors for vapor phase (most energy)

-

getMassFraction(model, molfraction)¶ Convert molar fraction to mass fraction

-

getMixtureFugacityCoefficients(model, P, T, x, y, acf)¶ Calculate intermediate values for fugacity computation

-

getMoleFraction(model, massfraction)¶ Convert mass fraction to molar fraction

-

getPhaseFractionAsADI(model, state, p, T, z)¶ Compute derivatives for values obtained by solving the equilibrium equations (molar fractions in each phase, liquid mole fraction).

-

setZDerivatives(model, Z, A, B, cellJacMap)¶ Z comes from the solution of a cubic equation of state, so the derivatives are not automatically computed. By differentiating the cubic EOS manually and solving for dZ/du where u is some primary variable, we can still obtain derivatives without making any assumptions other than the EOS being a cubic polynomial

-

solveCubicEOS(model, A, B)¶ Peng Robinson equation of state in form used by Coats

-

stepFunction(model, state, state0, dt, drivingForces, linsolve, nonlinsolve, iteration, varargin)¶ #ok Compute a single step of the solution process for a given equation of state (thermodynamic flash calculation);

-

substitutionCompositionUpdate(model, P, T, z, K, L)¶ Determine overall liquid fraction

-

PropertyModel= None¶ Model to be used for property evaluations

-

fluid= None¶ CompositionalFluid

-

minimumComposition= u'1e-8'¶ Minimum composition value (for numerical stability)

-

omegaA= None¶ Parameter for EOS

-

omegaB= None¶ Parameter for EOS

-

selectGibbsMinimum= u'true'¶ Use minimum Gibbs energy to select Z

-

useNewton= None¶ Use Newton based solver for flash. If set to false, successive substitution if used instead.

-

-

class

EquilibriumConstantModel(G, fluid, k_values)¶ Bases:

EquationOfStateModelEquilibrium constant EOS model for problems where functions of the type K(p, T, z) is sufficient to describe the phase behavior

Fluid models¶

-

Contents¶ FLUIDS

- Files

- BlackOilPropertyModel - Black-oil property model for compositional models CompositionalFluid - CompositionalPropertyModel - Property model for compositional models CoolPropsCompositionalFluid - Create MRST compositional fluid by using the open CoolProp library getCompositionalFluidCase - Grab bag of different fluids for use in examples etc PropertyModel - Base class for properties in the compositional module TableCompositionalFluid - Create MRST compositional from stored tables (taken from CoolProp)

-

class

BlackOilPropertyModel(rho, mu, satfn, varargin)¶ Bases:

PropertyModelBlack-oil property model for compositional models

-

class

CompositionalPropertyModel(varargin)¶ Bases:

PropertyModelProperty model for compositional models

-

computeDensity(model, p, x, Z, T, isLiquid)¶ Predict mass density from EOS Z-factor

-

computeMolarDensity(model, p, x, Z, T, isLiquid)¶ Predict molar density from EOS Z-factor

-

computePseudoCriticalPhaseProperties(model, x)¶ Molar fraction weighted aggregated properties to get pseudocritical properties of mixture.

-

computeViscosity(model, P, x, Z, T, isLiquid)¶ Compute viscosity using the Lohrenz, Bray and Clark correlation for hydrocarbon mixtures (LBC viscosity)

-

-

class

CoolPropsCompositionalFluid(names)¶ Bases:

CompositionalFluidCreate MRST compositional fluid by using the open CoolProp library (can be downloaded from http://www.coolprop.org/)

-

CoolPropsCompositionalFluid(names)¶ Create fluid from names

Synopsis:

f = TableCompositionalFluid({'Methane', 'n-Decane'});

Parameters: names – Cell array of valid names. See getFluidListfor valid names.Returns: fluid – Initialized fluid.

-

-

class

PropertyModel(f)¶ Base class for properties in the compositional module

-

class

TableCompositionalFluid(names)¶ Bases:

CompositionalFluidCreate MRST compositional from stored tables (taken from CoolProp)

-

TableCompositionalFluid(names)¶ Create fluid from names

Synopsis:

f = TableCompositionalFluid({'Methane', 'n-Decane'});

Parameters: names – Cell array of valid names. See getFluidListfor valid names.Returns: fluid – Initialized fluid.

-

-

getCompositionalFluidCase(name, varargin)¶ Grab bag of different fluids for use in examples etc

-

Contents¶ BLACKOIL

- Files

- blackOilToMassFraction - Evaluate properties convertBlackOilModelToCompositionalModel - Convert blackoil model to compositional-like model convertBlackOilStateToCompositional - Convert BO state to compositional-like state convertRSRVtoKValue - Convert RS/RV b lackoil to K-value. Experimental!

-

blackOilToMassFraction(model, p, sO, sG, rs, rv)¶ Evaluate properties

-

convertBlackOilModelToCompositionalModel(bomodel, varargin)¶ Convert blackoil model to compositional-like model

-

convertBlackOilStateToCompositional(bomodel, state)¶ Convert BO state to compositional-like state

-

convertRSRVtoKValue(model, varargin)¶ Convert RS/RV b lackoil to K-value. Experimental!

Note

Does not yet support RV.

Examples¶

Example comparing natural variables and overall composition with boundary conditions¶

Generated from compositionalBoundaryConditionsExample.m

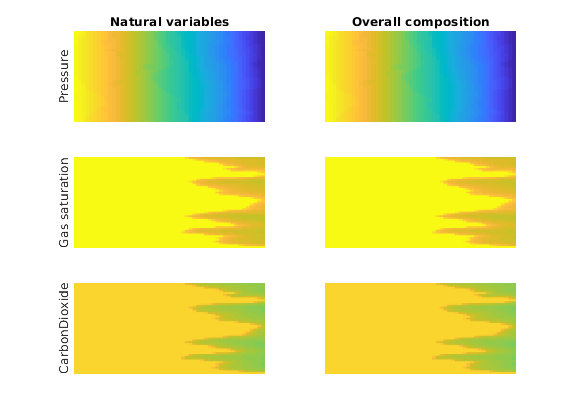

We simulate injection of CO2 using boundary conditions and compare two formulations for the same problem in terms of results and nonlinear iterations.

mrstModule add compositional ad-core ad-props

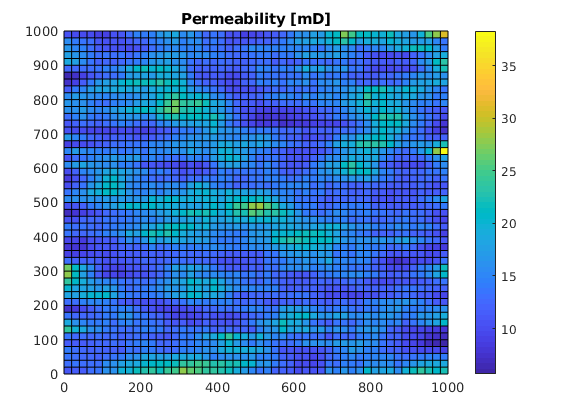

Set up problem¶

nx = 50;

ny = 50;

% Quadratic domain

dims = [nx, ny, 1];

pdims = [1000, 1000, 10];

G = cartGrid(dims, pdims);

G = computeGeometry(G);

% Generate a random Gaussian permeability field

rng(0);

K = logNormLayers(G.cartDims);

K = K(G.cells.indexMap);

rock = makeRock(G, K*milli*darcy, 0.2);

figure;

plotCellData(G, K);

colorbar;

title('Permeability [mD]');

Set up compositional fluid model¶

Three-component system of Methane, CO2 and n-Decane

names = {'Methane' 'CarbonDioxide' 'n-Decane'};

% Critical temperatures

Tcrit = [190.5640 304.1282 617.7000];

% Critical pressure

Pcrit = [4599200 7377300 2103000];

% Critical volumes

Vcrit = [9.8628e-05 9.4118e-05 6.0976e-04];

% Acentric factors

acentricFactors = [0.0114 0.2239 0.4884];

% Mass of components (as MRST uses strict SI, this is in kg/mol)

molarMass = [0.0160 0.0440 0.1423];

% Initialize fluid

fluid = CompositionalFluid(names, Tcrit, Pcrit, Vcrit, acentricFactors, molarMass);

Set up initial state and boundar conditions¶

We inject one pore-volume over 20 years. The right side of the domain is fixed at 75 bar.

minP = 75*barsa;

totTime = 20*year;

pv = poreVolume(G, rock);

bc = [];

bc = fluxside(bc, G, 'xmin', sum(pv)/totTime, 'sat', [1, 0]);

bc = pside(bc, G, 'xmax', minP, 'sat', [1, 0]);

bc.components = repmat([0.1, 0.9, 0], numel(bc.face), 1);

flowfluid = initSimpleADIFluid('rho', [1000, 500, 500], ...

'mu', [1, 1, 1]*centi*poise, ...

'n', [2, 2, 2], ...

'c', [1e-5, 0, 0]/barsa);

ncomp = fluid.getNumberOfComponents();

s0 = [1, 0];

state0 = initResSol(G, 1.5*minP, s0);

T = 423.15;

state0.T = repmat(T, G.cells.num, 1);

state0.components = repmat([0.3000 0.1000 0.6000], G.cells.num, 1);

dt = rampupTimesteps(totTime, 75*day, 12);

schedule = simpleSchedule(dt, 'bc', bc);

Solve with natural variables¶

Natural variables is one possible variable set for compositional problems. These variables include saturations, making it easier to limit updates for problems with strong relative permeability effects.

model = NaturalVariablesCompositionalModel(G, rock, flowfluid, fluid, 'water', false);

nls = NonLinearSolver('useRelaxation', true);

[~, states, report] = simulateScheduleAD(state0, model, schedule, 'nonlinearsolver', nls);

Solving timestep 001/110: -> 1582 Seconds, 31 Milliseconds

Solving timestep 002/110: 1582 Seconds, 31 Milliseconds -> 3164 Seconds, 62 Milliseconds

Solving timestep 003/110: 3164 Seconds, 62 Milliseconds -> 1 Hour, 2728 Seconds, 125.00 Milliseconds

Solving timestep 004/110: 1 Hour, 2728 Seconds, 125.00 Milliseconds -> 3 Hours, 1856 Seconds, 250.00 Milliseconds

Solving timestep 005/110: 3 Hours, 1856 Seconds, 250.00 Milliseconds -> 7 Hours, 112 Seconds, 500.00 Milliseconds

Solving timestep 006/110: 7 Hours, 112 Seconds, 500.00 Milliseconds -> 14 Hours, 225 Seconds

Solving timestep 007/110: 14 Hours, 225 Seconds -> 1 Day, 4 Hours, 450.00 Seconds

Solving timestep 008/110: 1 Day, 4 Hours, 450.00 Seconds -> 2 Days, 8 Hours, 900.00 Seconds

...

Solve using overall composition¶

Another formulation is to use composition variables with no saturations. In this formulation, the flash is solved between each nonlinear update.

model_o = OverallCompositionCompositionalModel(G, rock, flowfluid, fluid, 'water', false);

[~, states_o, report_o] = simulateScheduleAD(state0, model_o, schedule, 'nonlinearsolver', nls);

Solving timestep 001/110: -> 1582 Seconds, 31 Milliseconds

Solving timestep 002/110: 1582 Seconds, 31 Milliseconds -> 3164 Seconds, 62 Milliseconds

Solving timestep 003/110: 3164 Seconds, 62 Milliseconds -> 1 Hour, 2728 Seconds, 125.00 Milliseconds

Solving timestep 004/110: 1 Hour, 2728 Seconds, 125.00 Milliseconds -> 3 Hours, 1856 Seconds, 250.00 Milliseconds

Solving timestep 005/110: 3 Hours, 1856 Seconds, 250.00 Milliseconds -> 7 Hours, 112 Seconds, 500.00 Milliseconds

Solving timestep 006/110: 7 Hours, 112 Seconds, 500.00 Milliseconds -> 14 Hours, 225 Seconds

Solving timestep 007/110: 14 Hours, 225 Seconds -> 1 Day, 4 Hours, 450.00 Seconds

Solving timestep 008/110: 1 Day, 4 Hours, 450.00 Seconds -> 2 Days, 8 Hours, 900.00 Seconds

...

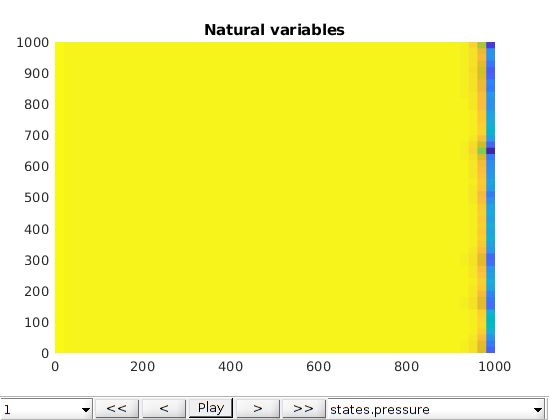

Launch interactive plotting¶

mrstModule add mrst-gui

figure;

plotToolbar(G, states)

title('Natural variables')

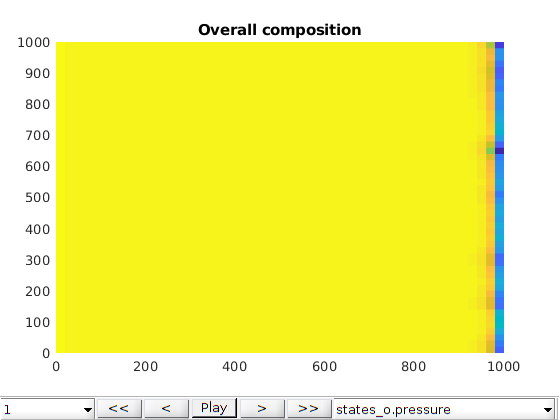

figure;

plotToolbar(G, states_o)

title('Overall composition')

Plot the pressure, gas saturation and CO2 mole fraction for both solvers¶

We compare the two results and see that they agree on the solution.

[h1, h2, h3, h4, h5, h6] = deal(nan);

h = figure;

for i = 1:numel(states_o)

figure(h);

if i > 1

delete(h1);

delete(h2);

delete(h3);

delete(h4);

delete(h5);

delete(h6);

end

subplot(3, 2, 1);

h1 = plotCellData(G, states{i}.pressure, 'EdgeColor', 'none');

axis tight; set(gca,'xticklabel',[],'yticklabel',[])

if i == 1

title('Natural variables')

ylabel('Pressure')

end

subplot(3, 2, 3);

h3 = plotCellData(G, states{i}.s(:, 2), 'EdgeColor', 'none');

axis tight; set(gca,'xticklabel',[],'yticklabel',[])

caxis([0, 1])

if i == 1

ylabel('Gas saturation')

end

subplot(3, 2, 5);

h5 = plotCellData(G, states{i}.components(:, 2), 'EdgeColor', 'none');

axis tight; set(gca,'xticklabel',[],'yticklabel',[])

caxis([0, 1])

if i == 1

ylabel(names{2})

end

subplot(3, 2, 2);

h2 = plotCellData(G, states_o{i}.pressure, 'EdgeColor', 'none');

if i == 1

title('Overall composition')

end

axis tight; set(gca,'xticklabel',[],'yticklabel',[])

subplot(3, 2, 4);

h4 = plotCellData(G, states_o{i}.s(:, 2), 'EdgeColor', 'none');

axis tight; set(gca,'xticklabel',[],'yticklabel',[])

caxis([0, 1])

subplot(3, 2, 6);

h6 = plotCellData(G, states_o{i}.components(:, 2), 'EdgeColor', 'none');

axis tight off; set(gca,'xticklabel',[],'yticklabel',[])

caxis([0, 1])

drawnow

end

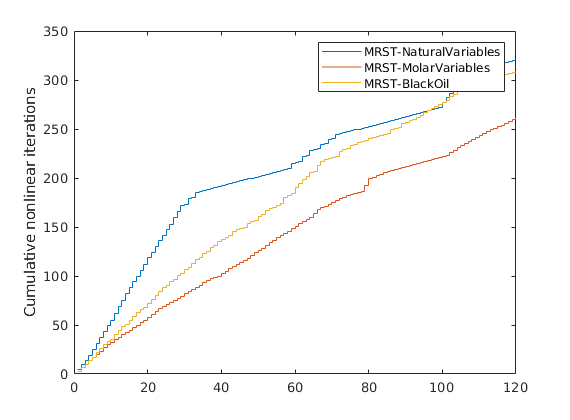

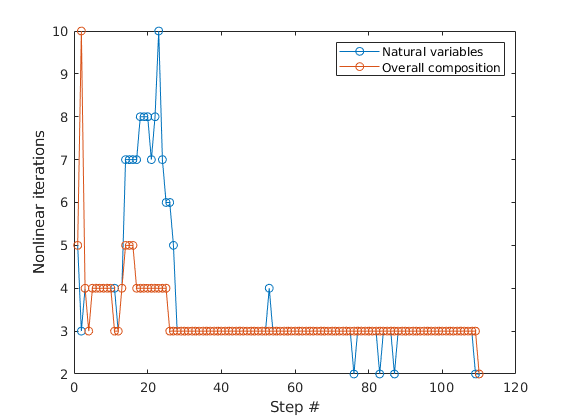

Plot the nonlinear iteration count¶

Different solvers are suitable for different problems. In this case, the overall composition model takes slightly fewer iterations.

figure;

plot([report.Iterations, report_o.Iterations], '-o')

legend('Natural variables', 'Overall composition')

xlabel('Step #')

ylabel('Nonlinear iterations')

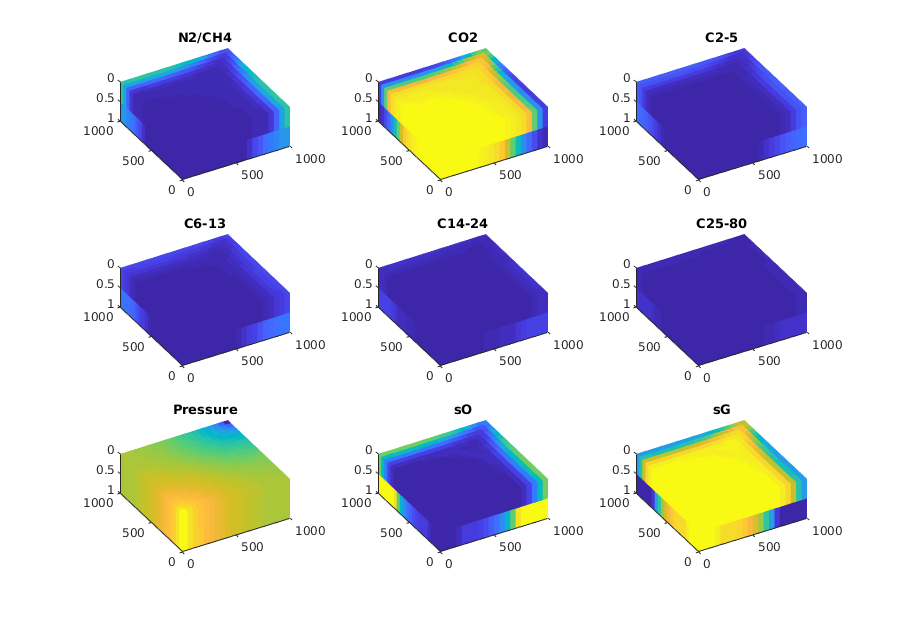

Example demonstrating a three dimensional, six component problem¶

Generated from compositionalExample3DSixComponents.m

We set up a simple grid and rock structure. The numbers can be adjusted to get a bigger/smaller problem. The default is a small problem with 20x20x2 grid blocks.

mrstModule add ad-core ad-props mrst-gui compositional

% Dimensions

nx = 20;

ny = nx;

nz = 2;

% Name of problem and pressure range

casename = 'lumped_1';

minP = 100*barsa;

maxP = 200*barsa;

% Set up grid and rock

dims = [nx, ny, nz];

pdims = [1000, 1000, 1];

G = cartGrid(dims, pdims);

G = computeGeometry(G);

rock = makeRock(G, 50*milli*darcy, 0.25);

Set up quarter five spot well pattern¶

We place vertical wells in opposing corners of the reservoir. The injector is rate controlled and the producer is bottom hole pressure controlled.

W = [];

% Injector

W = verticalWell(W, G, rock, 1, 1, [], 'comp_i', [1, 0], 'name', 'Inj',...

'Val', 0.0015, 'sign', 1, 'type', 'rate');

% Producer

W = verticalWell(W, G, rock, nx, ny, [], ...

'comp_i', [0.5, 0.5], 'Name', 'Prod', 'Val', minP, 'sign', -1, 'Type', 'bhp');

Set up model and initial state¶

We set up a problem with quadratic relative permeabilities. The fluid model is retrieved from “High Order Upwind Schemes for Two-Phase, Multicomponent Flow” (SPE 79691) by B. T. Mallison et al. The model consists of six components. Several of the components are not distinct molecules, but rather lumped groups of hydrocarbons with similar molecular weight. The reservoir contains all these components initially, which is then displaced by the injection of pure CO2.

nkr = 2;

[fluid, info] = getCompositionalFluidCase(casename);

flowfluid = initSimpleADIFluid('n', [nkr, nkr, nkr], 'rho', [1000, 800, 10]);

gravity reset on

model = NaturalVariablesCompositionalModel(G, rock, flowfluid, fluid, 'water', false);

ncomp = fluid.getNumberOfComponents();

state0 = initCompositionalState(G, minP + (maxP - minP)/2, info.temp, [0.5, 0.5], info.initial, model.EOSModel);

for i = 1:numel(W)

W(i).components = info.injection;

end

Set up schedule and simulate the problem¶

We simulate two years of production with a geometric rampup in the timesteps.

time = 2*year;

n = 45;

dt = rampupTimesteps(time, 7*day, 5);

schedule = simpleSchedule(dt, 'W', W);

[ws, states, rep] = simulateScheduleAD(state0, model, schedule);

Solving timestep 001/110: -> 5 Hours, 900 Seconds

Solving timestep 002/110: 5 Hours, 900 Seconds -> 10 Hours, 1800 Seconds

Solving timestep 003/110: 10 Hours, 1800 Seconds -> 21 Hours

Solving timestep 004/110: 21 Hours -> 1 Day, 18 Hours

Solving timestep 005/110: 1 Day, 18 Hours -> 3 Days, 12 Hours

Solving timestep 006/110: 3 Days, 12 Hours -> 7 Days

Solving timestep 007/110: 7 Days -> 14 Days

Solving timestep 008/110: 14 Days -> 21 Days

...

Plot all the results¶

lf = get(0, 'DefaultFigurePosition');

h = figure('Position', lf + [0, -200, 350, 200]);

nm = ceil(ncomp/2);

v = [-30, 60];

for step = 1:numel(states)

figure(h); clf

state = states{step};

for i = 1:ncomp

subplot(nm, 3, i);

plotCellData(G, state.components(:, i), 'EdgeColor', 'none');

view(v);

title(fluid.names{i})

caxis([0, 1])

end

subplot(nm, 3, ncomp + 1);

plotCellData(G, state.pressure, 'EdgeColor', 'none');

view(v);

title('Pressure')

subplot(nm, 3, ncomp + 2);

plotCellData(G, state.s(:, 1), 'EdgeColor', 'none');

view(v);

title('sO')

subplot(nm, 3, ncomp + 3);

plotCellData(G, state.s(:, 2), 'EdgeColor', 'none');

view(v);

title('sG')

drawnow

end

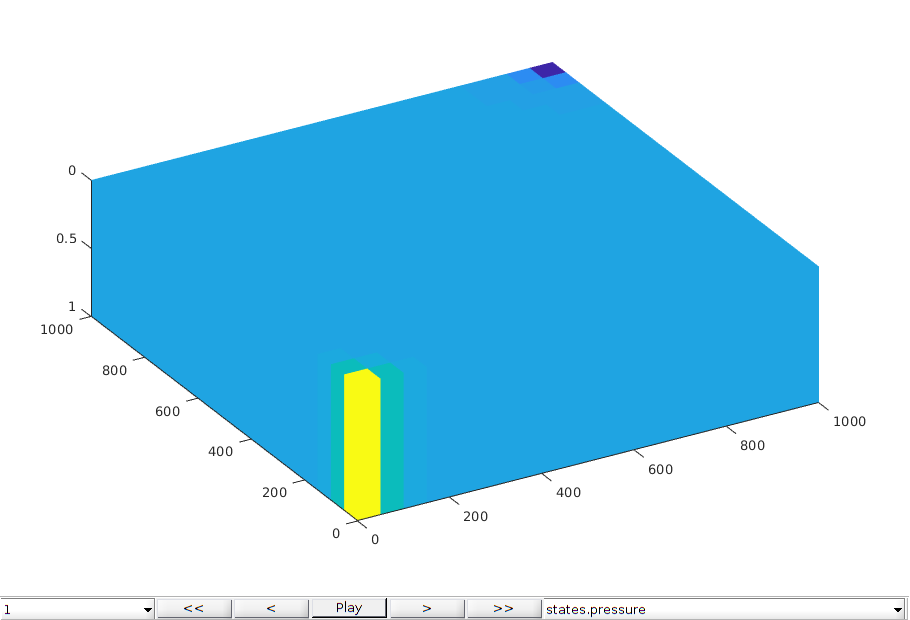

Plot the results in the interactive viewer¶

figure(1); clf;

plotToolbar(G, states)

view(v);

axis tight

Copyright notice¶

<html>

% <p><font size="-1

Conceptual example on how to run larger compositional problems¶

Generated from compositionalLargerProblemTutorial.m

The default settings of the compositional module are suitable for small problems and should work on most configurations with a recent Matlab version. However, with an external linear solver and a change of backend, larger problems can be solved.

mrstModule add compositional ad-core linearsolvers ad-props

useBC = false; % Use BC instead of wells

includeWater = false; % Include aqueous phase

useNatural = true; % Use natural variables formulation

% Define a problem

gravity reset on

nx = 30;

ny = 30;

nz = 30;

dims = [nx, ny, nz];

pdims = [1000, 1000, 100];

G = cartGrid(dims, pdims);

G = computeGeometry(G);

% Random permeability field

rng(0);

K = logNormLayers(G.cartDims);

K = K(G.cells.indexMap);

rock = makeRock(G, K*milli*darcy, 0.2);

pv = poreVolume(G, rock);

% Take the SPE5 fluid model (six components)

[fluid, info] = getCompositionalFluidCase('spe5');

minP = 0.5*info.pressure;

totTime = 10*year;

% Set up driving forces

[bc, W] = deal([]);

if useBC

bc = fluxside(bc, G, 'xmin', sum(pv)/totTime, 'sat', [0, 1, 0]);

bc = pside(bc, G, 'xmax', minP, 'sat', [0, 1, 0]);

bc.components = repmat(info.injection, numel(bc.face), 1);

else

W = verticalWell(W, G, rock, 1, 1, 1, 'comp_i', [0, 1, 0], ...

'Type', 'rate', 'name', 'Inj', 'Val', sum(pv)/totTime, 'sign', 1);

W = verticalWell(W, G, rock, nx, ny, nz, ...

'comp_i', [0, 0.5, 0.5], 'Name', 'Prod', 'Val', minP, 'sign', -1);

for i = 1:numel(W)

W(i).components = info.injection;

end

end

flowfluid = initSimpleADIFluid('rho', [1000, 500, 500], ...

'mu', [1, 1, 1]*centi*poise, ...

'n', [2, 2, 2], ...

'c', [1e-5, 0, 0]/barsa);

Initialize models¶

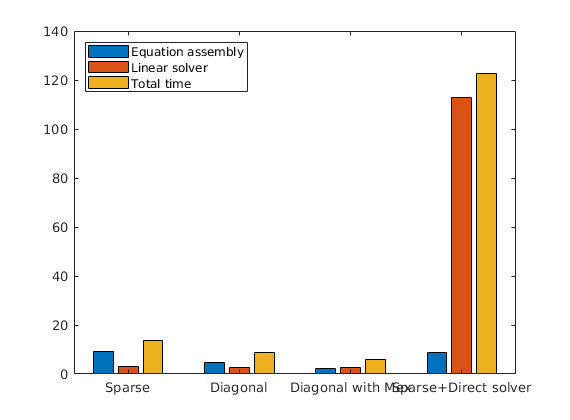

We initialize two models: The first uses the standard constructor, and uses the Sparse backend for AD. The second example uses the Diagonal AD backend instead, which is faster for problems with a moderate to many degrees of freedom and several components. The third option is to extended the diagonal backend with C++-acceleration through a mex interface. A compiler must be available (see mex -setup) for this to work. Note that the first simulation with diagonal+mex will occasionally stop to compile subroutines, so the user is encouraged to repeat the benchmark if this is the case. The performance of the backends varies from configuration to configuration, so the user is encouraged to test different versions until the best speed is found.

arg = {G, rock, flowfluid, fluid, 'water', includeWater};

diagonal_backend = DiagonalAutoDiffBackend('modifyOperators', true);

mex_backend = DiagonalAutoDiffBackend('modifyOperators', true, 'useMex', true);

sparse_backend = SparseAutoDiffBackend();

if useNatural

constructor = @GenericNaturalVariablesModel;

else

constructor = @GenericOverallCompositionModel;

end

modelSparseAD = constructor(arg{:}, 'AutoDiffBackend', sparse_backend);

modelDiagonalAD = constructor(arg{:}, 'AutoDiffBackend', diagonal_backend);

modelMexDiagonalAD = constructor(arg{:}, 'AutoDiffBackend', mex_backend);

Set up driving forces and initial state¶

ncomp = fluid.getNumberOfComponents();

if includeWater

s0 = [0.2, 0.8, 0];

else

s0 = [1, 0];

for i = 1:numel(W)

W(i).compi = W(i).compi(2:end);

end

if ~isempty(bc)

bc.sat = bc.sat(:, 2:end);

end

end

state0 = initCompositionalState(G, info.pressure, info.temp, s0, info.initial, modelSparseAD.EOSModel);

Pick linear solver¶

The AMGCL library is one possible solver option for MRST. It is fairly easy to write interfaces to other solvers using MEX files and/or the LinearSolverAD class. We call the routine for automatically selecting a reasonable linear solver for the specific model.

linsolve = selectLinearSolverAD(modelDiagonalAD);

disp(linsolve)

AMGCL-CPR-block linear solver of class AMGCL_CPRSolverAD

--------------------------------------------------------

AMGCL constrained-pressure-residual (CPR) solver. Configuration:

solver: gmres (Generalized minimal residual method. Parameters: gmres_m. Internal index 4)

preconditioner: amg (Algebraic multigrid Internal index 1)

relaxation: ilu0 (Incomplete LU-factorization with zero fill-in - ILU(0). Parameters: ilu_damping. Internal index 3)

coarsening: aggregation (Aggregation with constant interpolation. Parameters: aggr_eps_strong, aggr_over_interp, aggr_relax. Internal index 3)

s_relaxation: ilu0 (Incomplete LU-factorization with zero fill-in - ILU(0). Parameters: ilu_damping. Internal index 3)

...

Solve a single short step to benchmark assembly and solve time¶

shortSchedule = simpleSchedule(0.1*day, 'bc', bc, 'W', W);

nls = NonLinearSolver('LinearSolver', linsolve);

[~, statesSparse, reportSparse] = simulateScheduleAD(state0, modelSparseAD, shortSchedule, 'nonlinearsolver', nls);

[~, statesDiagonal, reportDiagonal] = simulateScheduleAD(state0, modelDiagonalAD, shortSchedule, 'nonlinearsolver', nls);

try

[~, statesMexDiagonal, reportMexDiagonal] = simulateScheduleAD(state0, modelMexDiagonalAD, shortSchedule, 'nonlinearsolver', nls);

catch

[statesMexDiagonal, reportMexDiagonal] = deal([]);

end

Solving timestep 1/1: -> 2 Hours, 1440 Seconds

*** Simulation complete. Solved 1 control steps in 13 Seconds, 469 Milliseconds ***

Solving timestep 1/1: -> 2 Hours, 1440 Seconds

*** Simulation complete. Solved 1 control steps in 8 Seconds, 644 Milliseconds ***

Solving timestep 1/1: -> 2 Hours, 1440 Seconds

*** Simulation complete. Solved 1 control steps in 5 Seconds, 971 Milliseconds ***

Solve using direct solver¶

This system is too large for the standard direct solver in Matlab. This may take some time!

[~, ~, reportDirect] = simulateScheduleAD(state0, modelSparseAD, shortSchedule);

Solving timestep 1/1: -> 2 Hours, 1440 Seconds

*** Simulation complete. Solved 1 control steps in 122 Seconds, 597 Milliseconds ***

Plot the time taken to solve a single step¶

figure(1 + useNatural); clf

getTime = @(report) [sum(cellfun(@(x) x.AssemblyTime, report.ControlstepReports{1}.StepReports{1}.NonlinearReport)), ...

% Assembly

sum(cellfun(@(x) x.LinearSolver.SolverTime, report.ControlstepReports{1}.StepReports{1}.NonlinearReport(1:end-1))),...

% Linear solver

sum(report.SimulationTime), ...

];

time_sparse = getTime(reportSparse);

time_diagonal = getTime(reportDiagonal);

time_direct = getTime(reportDirect);

if isempty(reportMexDiagonal)

time = [time_sparse; time_diagonal; time_direct];

bar(time)

set(gca, 'XTickLabel', {'Sparse', 'Diagonal', 'Sparse+Direct solver'});

else

time_mex = getTime(reportMexDiagonal);

time = [time_sparse; time_diagonal; time_mex; time_direct];

bar(time)

set(gca, 'XTickLabel', {'Sparse', 'Diagonal', 'Diagonal with Mex', 'Sparse+Direct solver'});

end

legend('Equation assembly', 'Linear solver', 'Total time', 'Location', 'NorthWest')

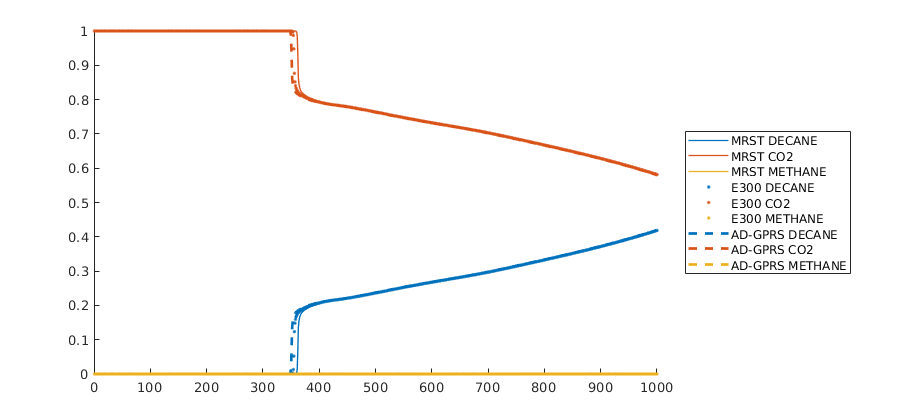

Compare MRST results with other simulators¶

Generated from compositionalValidationSimple.m

This example is a two-phase compositional problem where CO2 is injected into a mixture of CO2, Methane and Decane. The problem consists of 1000 cells and is one dimensional for ease of visualization. The problem is divided into a large number of timesteps to ensure that the different simulators take approximately the same timesteps. The problem is challenging in terms of fluid physics because the pressure is relatively low, which makes the phase behavior highly pressure dependent and all components exist in both phases. Since the wells are set to bottom hole pressure controls, the fluid volume injected is dependent on correctly calculating the mobility and densities in the medium. MRST uses the Peng-Robinson equation of state by default and the Lohrenz, Bray and Clark (LBC) correlation to determine viscosities for both phases.

mrstModule add compositional deckformat ad-core ad-props

Set up model¶

MRST includes both natural variables and overall composition. This toggle can switch between the modes.

useNatural = true;

pth = getDatasetPath('simplecomp');

fn = fullfile(pth, 'SIMPLE_COMP.DATA');

% Read deck

deck = readEclipseDeck(fn);

deck = convertDeckUnits(deck);

% Set up grid

G = initEclipseGrid(deck);

G = computeGeometry(G);

% Set up rock

rock = initEclipseRock(deck);

rock = compressRock(rock, G.cells.indexMap);

fluid = initDeckADIFluid(deck);

% Define some surface densities

fluid.rhoOS = 800;

fluid.rhoGS = 10;

eos = initDeckEOSModel(deck);

if useNatural

model = NaturalVariablesCompositionalModel(G, rock, fluid, eos.fluid, 'water', false);

else

model = OverallCompositionCompositionalModel(G, rock, fluid, eos.fluid, 'water', false);

end

schedule = convertDeckScheduleToMRST(model, deck);

% Manually set the injection composition

[schedule.control.W.components] = deal([0, 1, 0]);

% Injection is pure gas

[schedule.control.W.compi] = deal([1, 0]);

Warning: Could not assign property 'STCOND'. Encountered error: 'Undefined

function 'assignSTCOND' for input arguments of type 'struct'.'

Set up initial state¶

The problem is defined at 150 degrees celsius with 75 bar initial pressure. We set up the initial problem and make a call to the flash routines to get correct initial composition.

ncomp = eos.fluid.getNumberOfComponents();

for i = 1:numel(schedule.control.W)

schedule.control.W(i).lims = [];

end

% Initial conditions

z0 = [0.6, 0.1, 0.3];

T = 150 + 273.15;

p = 75*barsa;

state0 = initCompositionalState(G, p, T, 1, z0, eos);

Simulate the schedule¶

Note that as the poblem has 500 control steps, this may take some time (upwards of 4 minutes).

[ws, states, rep] = simulateScheduleAD(state0, model, schedule);

Solving timestep 001/500: -> 864 Seconds

Solving timestep 002/500: 864 Seconds -> 2592 Seconds

Solving timestep 003/500: 2592 Seconds -> 1 Hour, 2448 Seconds

Solving timestep 004/500: 1 Hour, 2448 Seconds -> 2 Hours, 2304 Seconds

Solving timestep 005/500: 2 Hours, 2304 Seconds -> 4 Hours, 2016 Seconds

Solving timestep 006/500: 4 Hours, 2016 Seconds -> 8 Hours, 1440 Seconds

Solving timestep 007/500: 8 Hours, 1440 Seconds -> 16 Hours, 288 Seconds

Solving timestep 008/500: 16 Hours, 288 Seconds -> 1 Day, 2 Hours, 2304.00 Seconds

...

Comparison plots with existing simulators¶

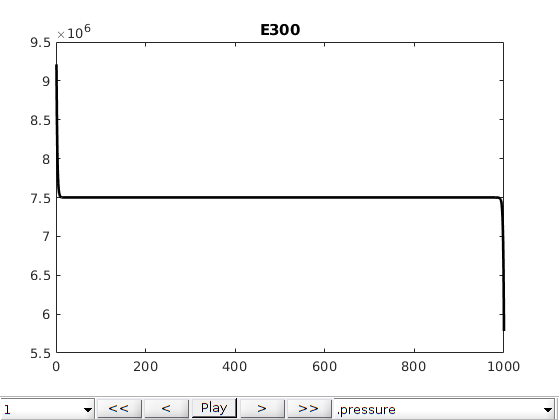

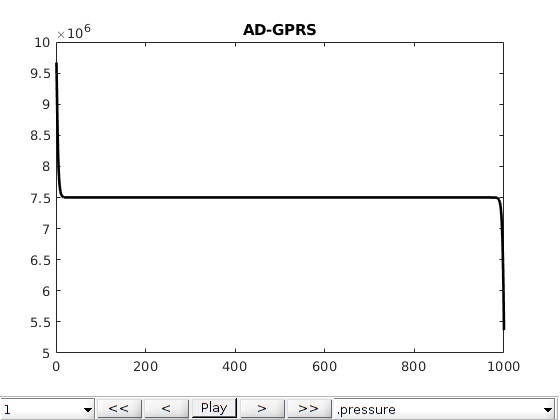

The same problem was defined into two other simulators: Eclipse 300 (which is a commercial simulator) and AD-GPRS (Stanford’s research simulator). We load in precomputed states from these simulators and compare the results. Note that the shock speed is sensitive to the different tolerances in the simulators, which have not been adjusted from the default in either simulator. We observe good agreement between all three simulators, with the minor differences can likely be accounted for by harmonizing the tolerances and sub-timestepping strategy for the different simulators.

lf = get(0, 'DefaultFigurePosition');

h = figure('Position', lf + [0, 0, 350, 0]);

ref = load(fullfile(pth, 'comparison.mat'));

data = {states, ref.statesECL, ref.statesGPRS};

n = min(cellfun(@numel, data));

names = {'MRST', 'E300', 'AD-GPRS'};

markers = {'-', '.', '--'};

cnames = model.EOSModel.fluid.names;

nd = numel(data);

l = cell(nd*ncomp, 1);

for i = 1:nd

for j = 1:ncomp

l{(i-1)*ncomp + j} = [names{i}, ' ', cnames{j}];

end

end

lw = [1, 2, 2];

colors = lines(ncomp);

for step = 1:n

figure(h); clf; hold on

for i = 1:numel(data)

s = data{i}{step};

comp = s.components;

if iscell(comp)

comp = [comp{:}];

end

for j = 1:ncomp

plot(comp(:, j), markers{i}, 'linewidth', lw(i), 'color', colors(j, :));

end

end

legend(l, 'location', 'eastoutside');

ylim([0, 1]);

drawnow

end

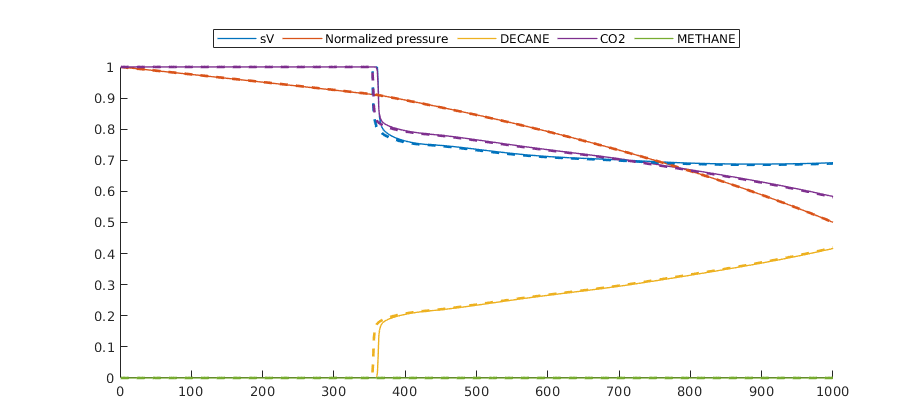

Compare pressure and saturations¶

We also plot a more detailed comparison between MRST and E300 to show that the prediction of phase behavior is accurate.

colors = lines(ncomp + 2);

for step = 1:n

figure(h); clf; hold on

for i = 1:2

s = data{i}{step};

if i == 1

marker = '-';

linewidth = 1;

else

marker = '--';

linewidth = 2;

end

hs = plot(s.s(:, 2), marker, 'color', [0.913, 0.172, 0.047], 'linewidth', linewidth, 'color', colors(1, :));

p = s.pressure./max(s.pressure);

hp = plot(p, marker, 'linewidth', linewidth, 'color', colors(2, :));

comp = s.components;

if iscell(comp)

comp = [comp{:}];

end

if i == 1

handles = [hs; hp];

end

for j = 1:ncomp

htmp = plot(comp(:, j), marker, 'linewidth', linewidth, 'color', colors(j + 2, :));

if i == 1

handles = [handles; htmp];

end

end

if i == 2

legend(handles, 'sV', 'Normalized pressure', cnames{:}, 'location', 'northoutside', 'orientation', 'horizontal');

end

end

ylim([0, 1]);

drawnow

end

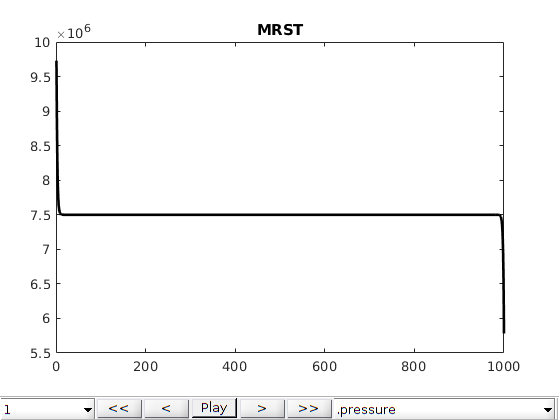

Set up interactive plotting¶

Finally we set up interactive plots to make it easy to look at the results from the different simulators.

mrstModule add mrst-gui

for i = 1:nd

figure;

plotToolbar(G, data{i}, 'plot1d', true);

title(names{i});

end

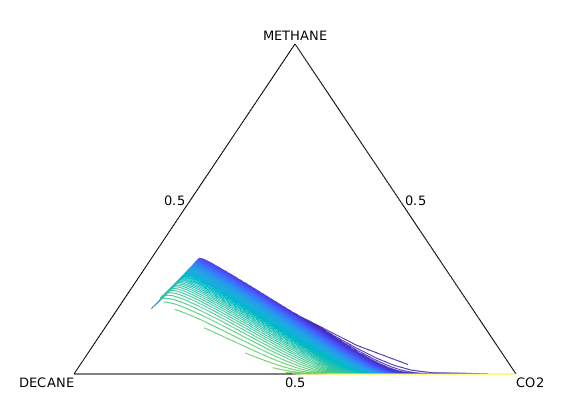

Plot displacement lines in ternary diagram¶

figure; hold on

plot([0, 0.5, 1, 0], [0, sqrt(3)/2, 0, 0], 'k')

mapx = @(x, y, z) (1/2)*(2*y + z)./(x + y+ z);

mapy = @(x, y, z) (sqrt(3)/2)*z./(x + y+ z);

colors = parula(numel(states));

for i = 1:5:numel(states)

C = states{i}.components;

plot(mapx(C(:, 1), C(:, 2), C(:, 3)), mapy(C(:, 1), C(:, 2), C(:, 3)), '-', 'color', colors(i, :))

end

axis off

text(0, 0, model.EOSModel.fluid.names{1}, 'verticalalignment', 'top', 'horizontalalignment', 'right')

text(1, 0, model.EOSModel.fluid.names{2}, 'verticalalignment', 'top', 'horizontalalignment', 'left')

text(0.5, sqrt(3)/2, model.EOSModel.fluid.names{3}, 'verticalalignment', 'bottom', 'horizontalalignment', 'center')

text(mapx(0.5, 0.5, 0), mapy(0.5, 0.5, 0), '0.5', 'verticalalignment', 'top', 'horizontalalignment', 'center')

text(mapx(0, 0.5, 0.5), mapy(0, 0.5, 0.5), '0.5', 'verticalalignment', 'bottom', 'horizontalalignment', 'left')

text(mapx(0.5, 0.0, 0.5), mapy(0.5, 0.0, 0.5), '0.5', 'verticalalignment', 'bottom', 'horizontalalignment', 'right')

Example demonstrating compositional solvers with K-values¶

Generated from runCompositionalSPE1.m

We solve SPE1 using two compositional models with the black-oil properties represented as pressure and composition-dependent equilibrium constants.

First, setup the base case¶

mrstModule add ad-core ad-blackoil compositional ad-props mrst-gui

[G, rock, fluid, deck, state] = setupSPE1();

model = ThreePhaseBlackOilModel(G, rock, fluid, 'disgas', true);

model.extraStateOutput = true;

schedule = convertDeckScheduleToMRST(model, deck);

Switch well limits¶

The compositional solvers use a different definition of oil-rate controls. For this reason, we adjust the control of the producer to use BHP.

schedule.control.W(2).type = 'bhp';

schedule.control.W(2).val = 200*barsa;

schedule.control.W(2).lims = [];

Convert state and wells¶

state0 = convertBlackOilStateToCompositional(model, state);

for i = 1:numel(schedule.control(1).W)

schedule.control(1).W(i).components = schedule.control(1).W(i).compi(2:end);

end

Convert model to compositional model¶

This is based on interpolation and is not completely robust.

modelNat = convertBlackOilModelToCompositionalModel(model, 'interpolation', 'pchip');

modelNat.FacilityModel = FacilityModel(modelNat);

modelNat.FacilityModel.toleranceWellRate = 1e-3;

modelNat.dsMaxAbs = 0.2;

modelNat.dzMaxAbs = inf;

modelNat.incTolPressure = inf;

Run natural variables¶

[wsNat, statesNat, reportNat] = simulateScheduleAD(state0, modelNat, schedule);

Solving timestep 001/120: -> 1 Day

Solving timestep 002/120: 1 Day -> 3 Days

Solving timestep 003/120: 3 Days -> 5 Days

Solving timestep 004/120: 5 Days -> 10 Days

Solving timestep 005/120: 10 Days -> 15 Days

Solving timestep 006/120: 15 Days -> 25 Days

Solving timestep 007/120: 25 Days -> 35 Days

Solving timestep 008/120: 35 Days -> 45 Days

...

Run overall composition¶

modelOverall = OverallCompositionCompositionalModel(G, rock, fluid, modelNat.EOSModel);

modelOverall.FacilityModel = FacilityModel(modelOverall);

modelOverall.FacilityModel.toleranceWellRate = modelNat.FacilityModel.toleranceWellRate;

modelOverall.dsMaxAbs = modelNat.dsMaxAbs;

modelOverall.dzMaxAbs = modelNat.dzMaxAbs;

modelOverall.incTolPressure = modelNat.incTolPressure;

[wsOverall, statesOverall, reportOverall] = simulateScheduleAD(state0, modelOverall, schedule);

Solving timestep 001/120: -> 1 Day

Solving timestep 002/120: 1 Day -> 3 Days

Solving timestep 003/120: 3 Days -> 5 Days

Solving timestep 004/120: 5 Days -> 10 Days

Solving timestep 005/120: 10 Days -> 15 Days

Solving timestep 006/120: 15 Days -> 25 Days

Solving timestep 007/120: 25 Days -> 35 Days

Solving timestep 008/120: 35 Days -> 45 Days

...

Run the reference¶

model.FacilityModel = FacilityModel(model);

model.FacilityModel.toleranceWellRate = modelNat.FacilityModel.toleranceWellRate;

[wsRef, statesRef, reportRef] = simulateScheduleAD(state, model, schedule);

Solving timestep 001/120: -> 1 Day

Solving timestep 002/120: 1 Day -> 3 Days

Solving timestep 003/120: 3 Days -> 5 Days

Solving timestep 004/120: 5 Days -> 10 Days

Solving timestep 005/120: 10 Days -> 15 Days

Solving timestep 006/120: 15 Days -> 25 Days

Solving timestep 007/120: 25 Days -> 35 Days

Solving timestep 008/120: 35 Days -> 45 Days

...

Store component rates for the reference solution in the same format¶

for i = 1:numel(wsRef)

for j = 1:numel(wsRef{i})

wsRef{i}(j).PseudoGas = wsRef{i}(j).qGs.*fluid.rhoGS;

wsRef{i}(j).PseudoOil = wsRef{i}(j).qOs.*fluid.rhoOS;

end

end

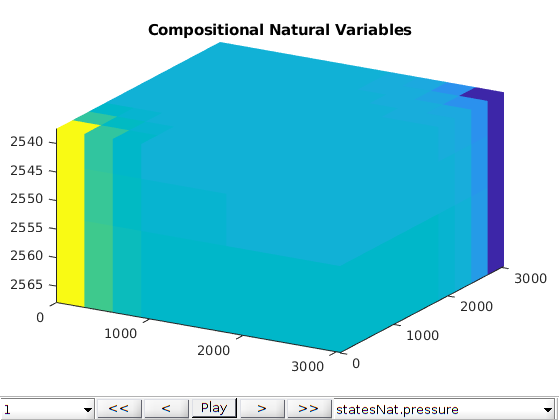

Add interactive plotting¶

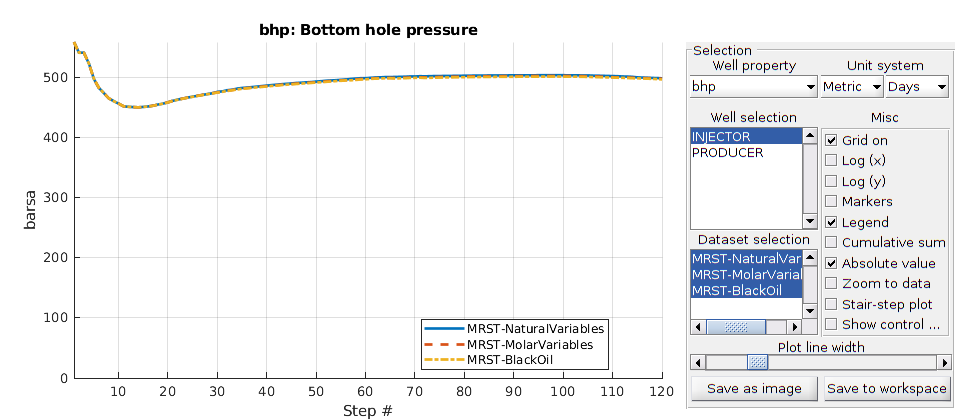

Note: Gas and oil rates in the producer are defined differently between the solvers, and will not match

names = {'MRST-NaturalVariables', 'MRST-MolarVariables', 'MRST-BlackOil'};

figure;

plotToolbar(G, statesNat);

title('Compositional Natural Variables')

axis tight

view(30, 30);

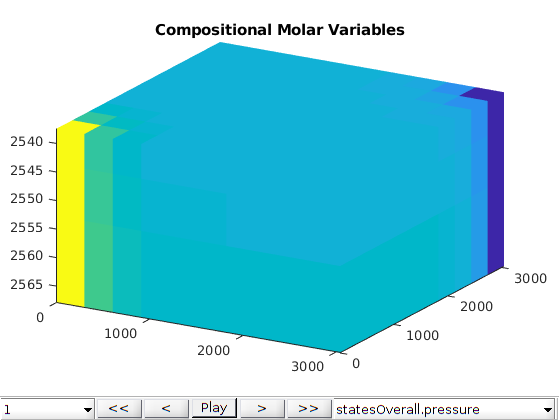

figure;

plotToolbar(G, statesOverall);

title('Compositional Molar Variables')

axis tight

view(30, 30);

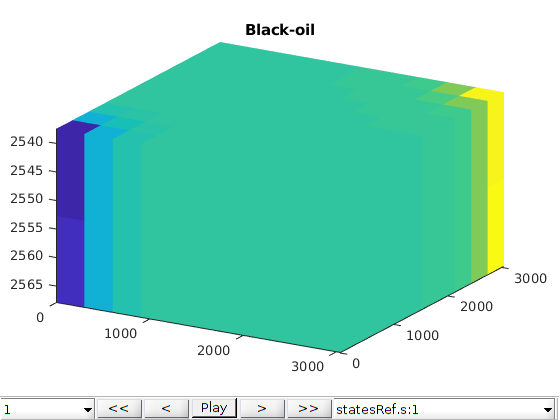

figure;

plotToolbar(G, statesRef);

title('Black-oil');

axis tight

view(30, 30);

plotWellSols({wsNat, wsOverall, wsRef}, 'datasetnames', names)

Plot nonlinear iterations¶

figure;

stairs(cumsum([reportNat.Iterations, reportOverall.Iterations, reportRef.Iterations]));

legend(names);

ylabel('Cumulative nonlinear iterations')